Bleeding hydraulics, Bleeding lift hydraulics, Bleeding fold cylinder hydraulics – Great Plains YP2425F-2470 Operator Manual User Manual

Page 94: Lift cylinder bleeding

90

YP2425 & YP2425F

Great Plains Manufacturing, Inc.

401-406M

2014-07-14

Bleeding Hydraulics

Bleeding Lift Hydraulics

Normally the lift hydraulics are bled at the factory before

shipping, and bleeding should not be required other than

to raise fully and hold lever on for one minute or until all

cylinders extend fully.

If it is necessary to further bleed lift system, see “Lift

Cylinder Bleeding” on page 90 below.

Bleeding Fold Cylinder Hydraulics

Normally the fold hydraulics are bled at the factory before

shipping, and bleeding should not be required other than

to fold fully and hold lever on for one minute or until all

cylinders reach the end of their stroke.

Erratic gage wheel behavior, such as wandering back

and forth in the field, or failing to rotate fully into place

while folding, are signs that the fold cylinders need to be

bled.

If it is necessary to further bleed fold system, see “Fold

Cylinder Bleeding” on page 91.

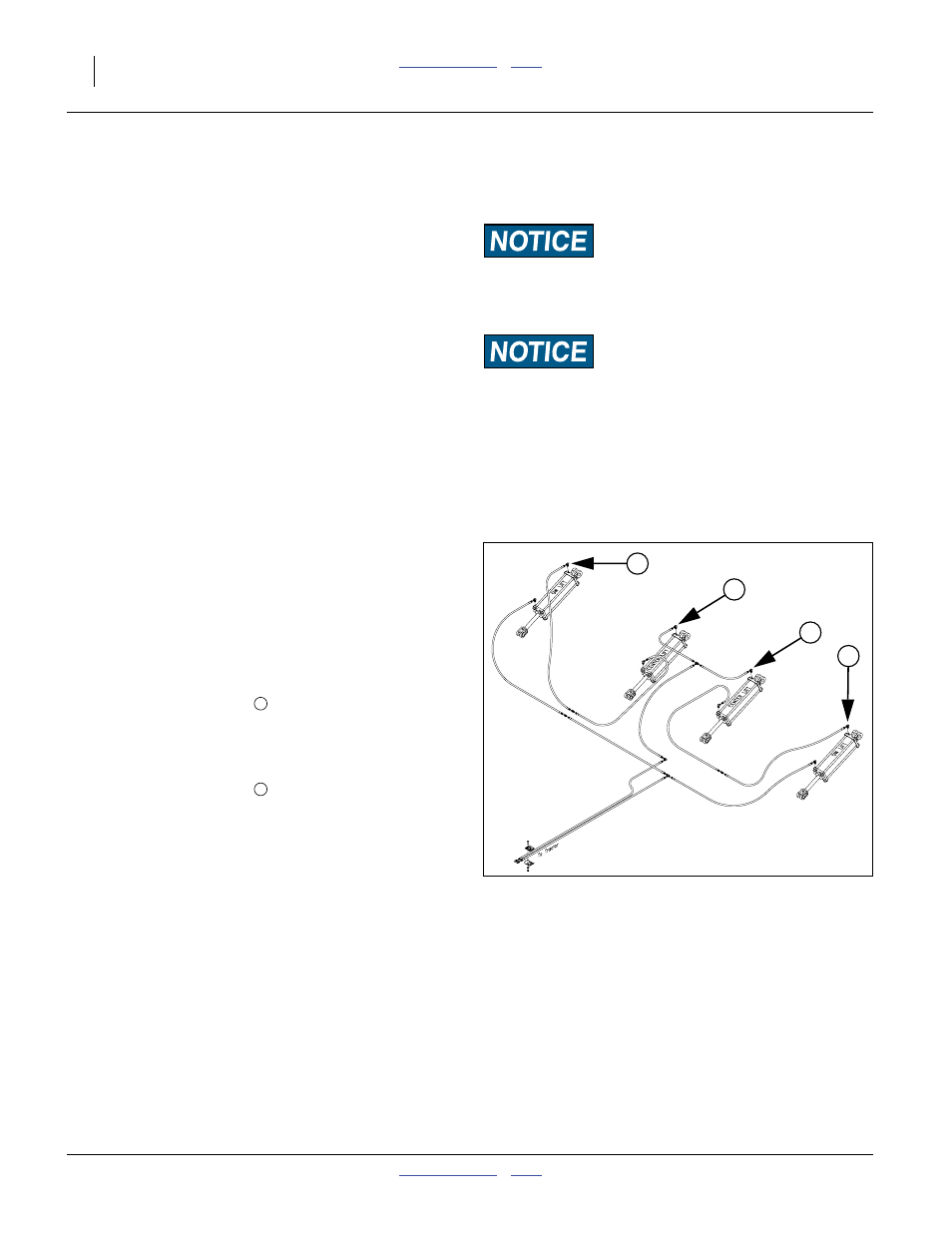

Lift Cylinder Bleeding

Unfold and lower planter.

2.

Un-pin rod ends of all lift cylinders. Position cylinders

so that rod ends may extend without striking

machine parts.

3.

Loosen the JIC fittings

master lift cylinder.

4.

Extend the circuit until fluid appears at the loosened

fittings. Set circuit to Neutral and secure fittings.

5.

Loosen the JIC fittings

slave lift cylinder.

6.

Extend the circuit until fluid appears at the loosened

fittings. Set circuit to Neutral and secure fittings.

7.

Re-pin rod ends.

Figure 119

Lift Bleed

25227

1

2

Machine Damage Risk:

Do not fold or unfold without first raising planter completely.

Machine Damage Risk:

Bleed lines only at:

JIC (Joint Industry Conference, 37

°

flare) or

NPT (National Pipe Thread, tapered thread) fittings.

Never bleed at:

ORB (O-Ring Boss) or

QD (Quick Disconnect) fittings.

1

2