Gauge/transport wheel adjustments, Marker adjustments, Gauge/transport wheel – Great Plains YP2425F-2470 Operator Manual User Manual

Page 56: Adjustments

52

YP2425 & YP2425F

Great Plains Manufacturing, Inc.

401-406M

2014-07-14

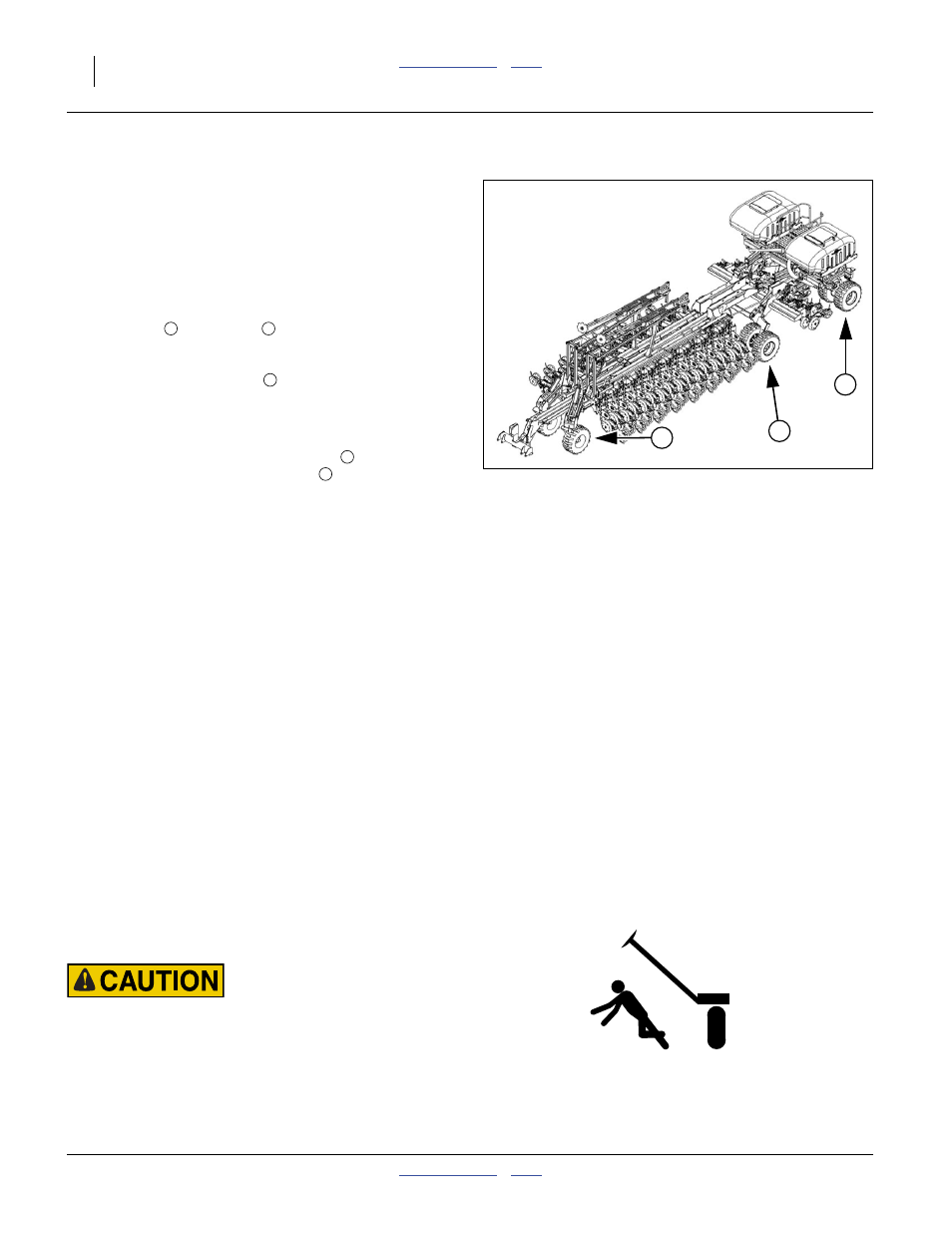

Gauge/Transport Wheel

Adjustments

The gauge/transport wheels serve two functions:

1.

When the planter is lowered, the wheels establish

the heights of their respective sections, nominally a

tool bar height of 26 inches (66 cm) above the

planting surface.

The main

and trailing

wheels are not adjustable

in height.

The wing gauge wheels

may be slightly raised or

lowered by adjusting a nut on the cylinder rod. See

“Wing Leveling, Inboard End” on page 23.

2.

When the planter is raised, all of these are the

transport wheels. The main wheels

are rigid, and

aid steering. The trailing wheels

are full castering.

The gauge wheels are usually adjusted only to bring all

sections to level.

Marker Adjustments

There are six adjustments for markers:

• Disk Angle

Even if your row spacing rarely changes, you may

need to adjust disk angle for soil conditions and

planting speed.

• Marker Extension

Once set for a specific row spacing, this only needs

periodic checking to ensure the clamp is secure.

• Marker Support Wheels

Three bolt holes are available for adjusting height.

• Shear Bolt Replacement

If a marker hangs up on an obstruction, a bolt at the

fold is designed to fail.

• Chain Length

This needs to be set if the chain is replaced. It may

also need adjustment for unusual terrain.

• Marker Speed

Once initially set by your dealer, this rarely needs

modification.

Sharp Overhead Object Hazard:

You may be injured if hit by a folding or unfolding marker.

Markers may fall quickly and unexpectedly if the hydraulics

fail. Never allow anyone near the planter when folding or

unfolding the markers.

Figure 56

Gauge Wheels

25205

3

1

2