25 series spreaders and scrapers, 25 series row-unit side wheels – Great Plains YP2425F-2470 Operator Manual User Manual

Page 100

96

YP2425 & YP2425F

Great Plains Manufacturing, Inc.

401-406M

2014-07-14

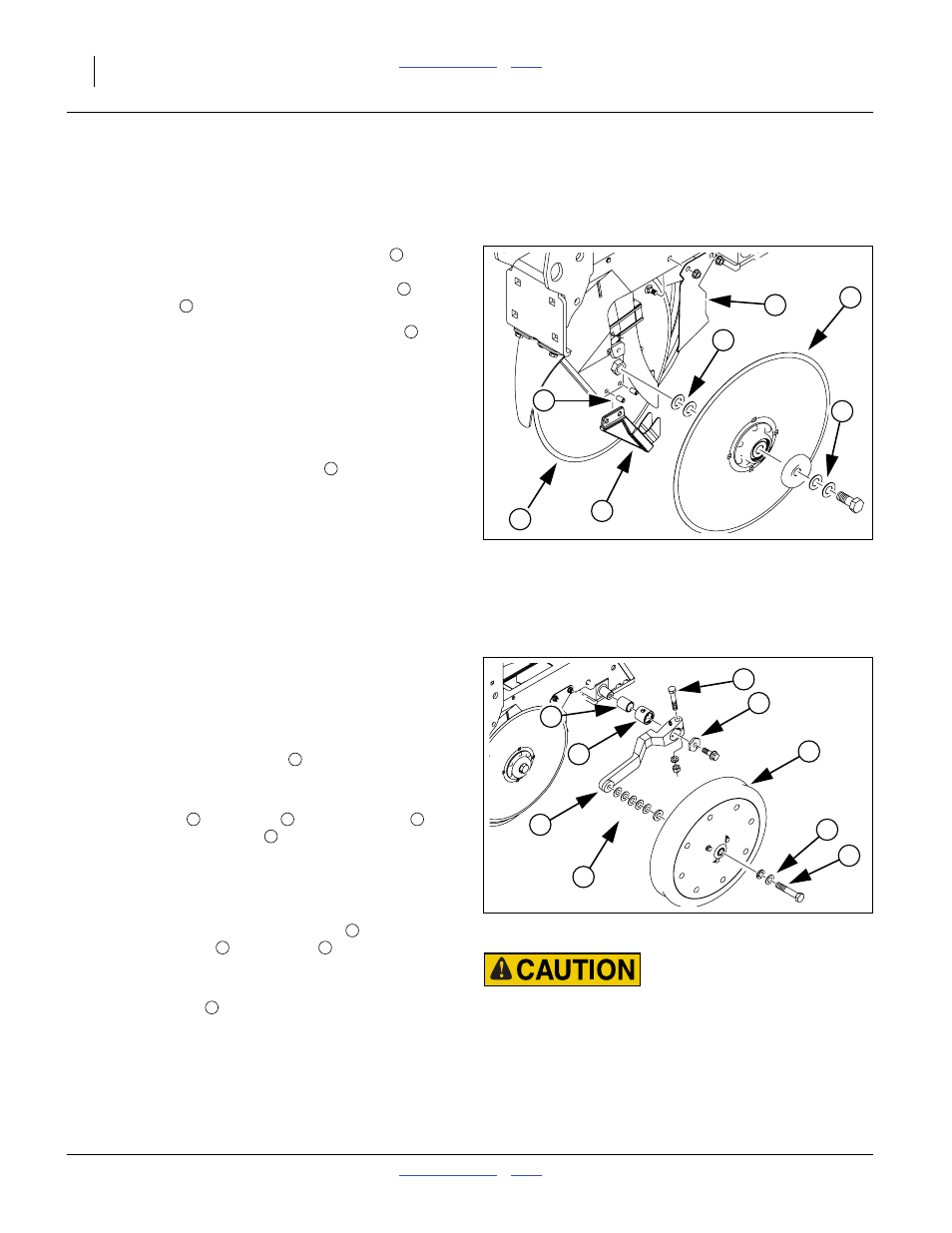

25 Series Spreaders and Scrapers

Remove side gauge wheels from arms to access

row-unit disks and scrapers.

2.

With the unit raised, check blade spreader

for

wear. Replace spreader if it is

1

⁄

2

inch (13 mm) wide

or narrower. To replace, remove disk blades

, drive

out roll pins

, and install new spreader.

3.

When reinstalling disk blades, put two shims

between bearing and shank on each blade. Tighten

bolts.

4.

Check amount of contact between blades, and adjust

number of shims as needed. Store extra shims on

outside of blade. See “Opener Disc Contact

Region” on page 72.

5.

Check that outside disk scrapers

are formed to

disk blades to help remove any mud. Bend/twist

scrapers to fit blades as needed. Every 200 acres of

operation, check outside scrapers for adjustment

and wear. Replace outside scrapers as necessary.

25 Series Row-Unit Side Wheels

1.

Lift opener side wheel off the ground. Move tire in

and out to check for end play. Check for roughness in

bearing by rotating wheel. If bearings are rough,

inspect and replace if necessary.

2.

Side wheels are preset at the factory. Due to normal

wear it may become necessary to make adjustments

so the wheel remains close to the disk. To prevent

plugging, loosen clamp bolt

and slide arm inward

to take up gap between side wheel and disk blade. If

more adjustment is needed, go to step 3.

3.

Remove bolt

and wheel

. Remove shims

from the inside of wheel

and place them on the

outside of wheel. Always place removed shims from

the inside to the outside. When installed, wheel

should turn freely and not hit the arm at the curve.

Do not add any more shims than necessary.

4.

Disassemble side gauge wheel arm

from unit.

Remove bushing

from sleeve

and check for

wear. If necessary, replace bushing.

5.

When reinstalling side gauge wheels, align tab on

hex adjustment

with notch in bushing. Replace

bolt and tighten.

6.

Adjust side gauge wheels. Refer to see “Side Gauge

Wheel Adjustment” on page 73.

1

2

4

5

3

4

3

Note: You may need fewer washer shims on worn disks.

Figure 130

Spreaders and Scraper

s

22839

Note: It is normal for the blade spreader to have some

looseness in the holder and between the blades.

Some looseness is required for proper operation.

1

3

2

4

5

{

4

2

3

8

1

7

6

5

4

Sharp Object Hazard:

Disk edges are sharp. Be careful when working in this area.

Figure 131

Side Gauge Wheel Shims

21894

1

2

3

4

3

5

6

7

8