Troubleshooting, General troubleshooting, Troubleshooting general troubleshooting – Great Plains YP2425F-2470 Operator Manual User Manual

Page 89

2014-07-14

401-406M

Great Plains Manufacturing, Inc.

85

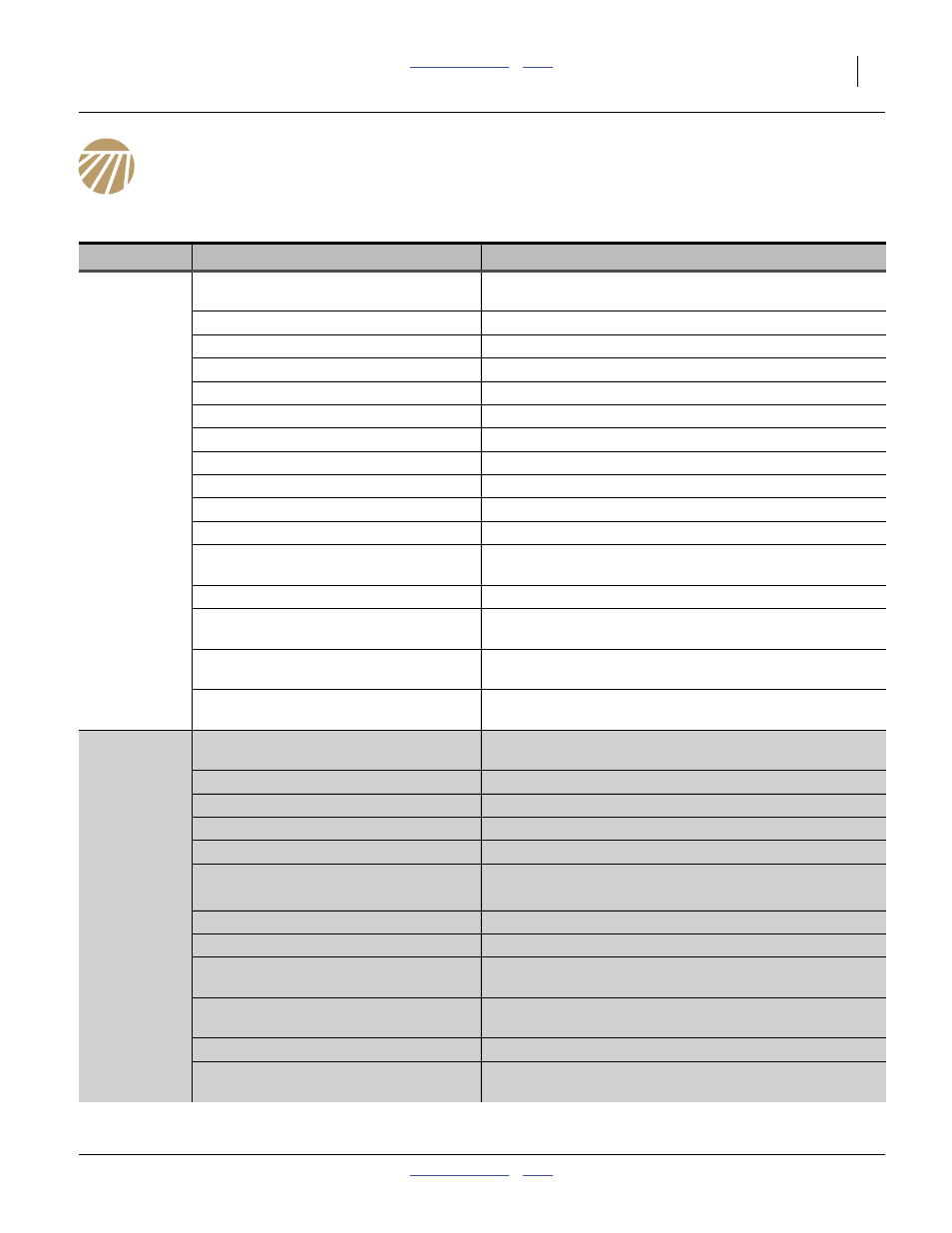

Troubleshooting

General Troubleshooting

Problem

Cause

Solution

Planting too

little

Incorrect seed size for meter wheel can

cause skips

Replace meter wheels to match seed

Meter drive not engaged

Engage drive coupler, page 68

Worn meter components

Replace worn components

Incorrect seed rate.

Check seed rate information.

Excessive field speed.

Reduce field speed.

Seed size and weight may vary.

Finger meter brush may need adjustment, page 79.

Incorrect tire size or air pressure.

Correct tire size and air pressure, page 121.

Incorrect fan air flow

Adjust fan speed and/or fan baffle, page 58

Excessive gaps between planter passes. Adjust marker, page 52.

Plugged row-unit seed tube.

Raise planter, expose bottom of seed tube and clean out.

Thrown or worn drive chains

Check drive chains.

Worn/rusted sprockets, chains and/or

chain idlers.

Replace sprockets, chains and/or chain idlers.

Improper sprocket.

Check sprockets

Speed sensor calibration

Perform calibration per DICKEY-john

®

documentation

with planter lowered.

Speed sensor angle.

With planter lowered, check radar speed sensor angle per

DICKEY-john

®

recommendations.

Meter wheel or finger pickup has fewer

cells than indicated on seed rate chart.

Charts are based on either 6 finger or 12 finger meters or

various wheel cell counts.

Planting too

much

Incorrect seed size for meter wheel can

cause doubles

Replace meter wheels to match seed

Worn meter components

Replace worn components

Meter clean-out door left open

Close door

Incorrect seed rate.

Check seed rate information in the seed monitor manual.

Actual field size is different.

Verify field size.

Excessive overlap.

Irregular shaped field.

Adjust marker, page 52.

Incorrect tire size or air pressure.

Correct tire size and air pressure, page 122.

Improper sprocket.

Check sprockets

Speed sensor calibration

Perform calibration per DICKEY-john

®

documentation

with planter lowered.

Speed sensor angle.

With planter lowered, check radar speed sensor angle per

DICKEY-john

®

recommendations.

Brush too loose on finger pickup meter

Adjust brush, page 79

Meter wheel or finger pickup has more

cells than indicated on seed rate chart.

Charts are based on either 6 finger or 12 finger meters or

various wheel cell counts.

For planters equipped with Row-Pro™, see also

“Row-Pro™ Troubleshooting” on page 149.