Great Plains YP2425F-2470 Operator Manual User Manual

Page 91

Great Plains Manufacturing, Inc.

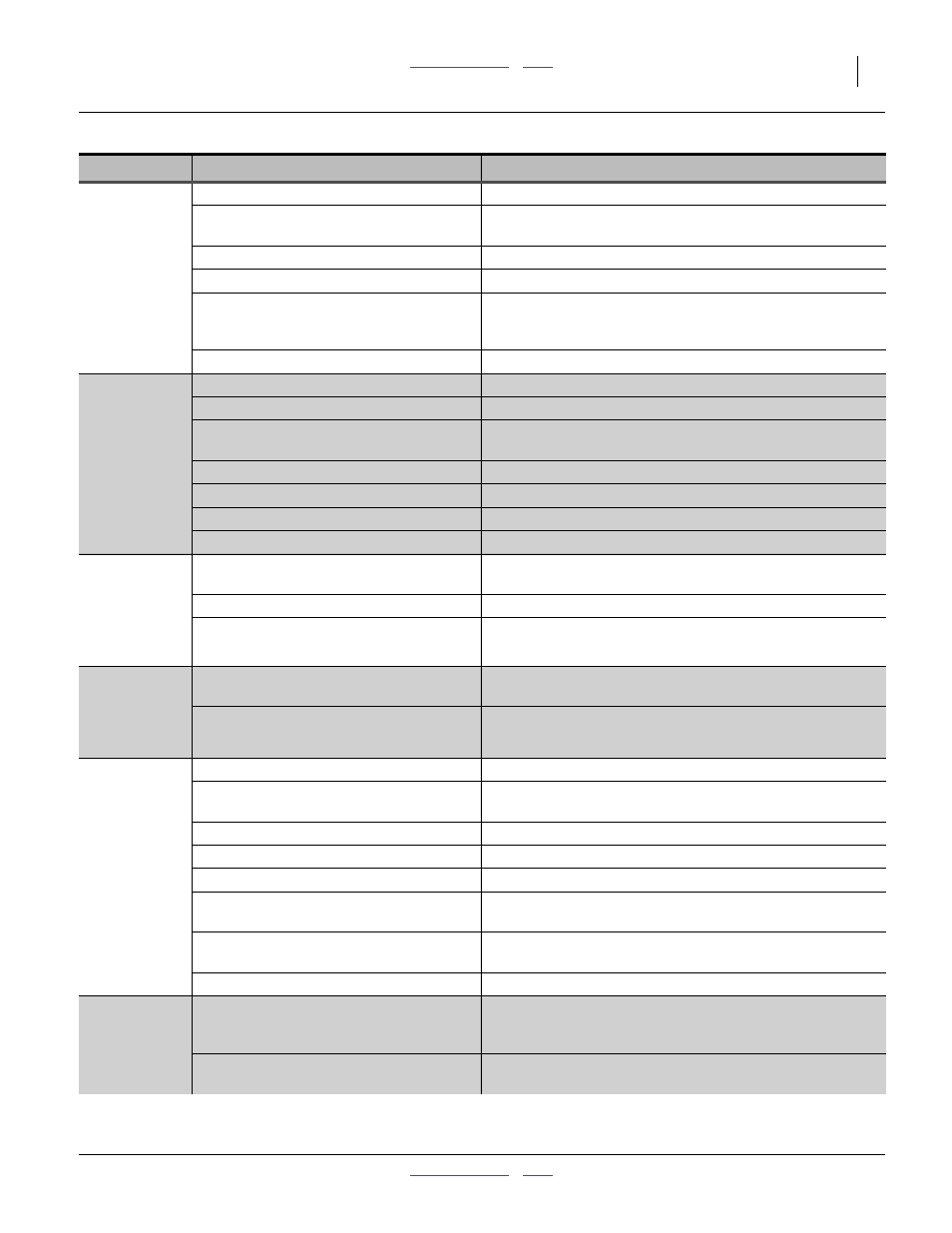

Troubleshooting

87

2014-07-14

401-406M

Press

wheels not

compacting

the soil as

desired.

Incorrect spring handle setting

See “Press Wheel Adjustment” on page 83.

Wheel stagger needs adjustment for

conditions

See “Press Wheel Adjustment” on page 83.

Insufficient row unit down force

See “Row Unit Down Pressure” on page 66.

Too wet or cloddy.

Wait until drier weather or rework ground.

Use of incorrectly shaped tire for your

conditions.

Wedge shaped wheels work best on narrow spacings and

in wet conditions. Round edge wheels work best in wider

row spacings and drier conditions.

Incorrect press wheel depth.

Reset press wheel depth, page 83.

Press wheel

or row-units

plugging

Planting conditions too wet.

Wait until drier weather.

Too much pressure on row-units.

Reduce down pressure on row-units.

Coulters set too deep, bring up excess

dirt and moisture.

Check coulter adjustment.

Backed up with planter in the ground.

Clean out and check for damage.

Failed disk bearings.

Replace disk bearings.

Disk blades worn.

Replace disk blades.

Scraper worn or damaged.

Replace scraper.

Air lines

plugging

between air

box and Y

splitters

Improper air hose routing.

With planter unfolded, hoses should form a gentle

horizontal “S” shape through the holders with no big sags.

Air leaks between manifold and splitters

Check for leaks and correct as needed.

Fan air flow too low.

Speed up fan. If already at 3800 rpm, increase airflow by

reducing butterfly valve angle, before increasing rpm.

Seed

blowing out

of Pro-Box

door area

Fan air flow too high.

Slow down fan. If already at or below 3000 rpm, set fan at

3800 rpm and use fan butterfly valve to reduce airflow.

Seal on top of airbox damaged or out of

adjustment.

Seal should be compressed approximately

1

⁄

2

inch when

hopper or box is installed.

Hydraulic

marker

functioning

improperly

Marker circuit set to Aux

Set Marker/Aux valve on wing to Marker. See page 47.

Air in lines or valves

Re-phase Marker cylinders, then see “Marker Cylinder

Bleeding” on page 91.

Leaks in hose fittings or connections.

Check all hose fittings and connections for air or oil leaks.

Low tractor hydraulic oil level.

Check tractor hydraulic oil level.

Loose or missing bolts or fasteners.

Check all bolts and fasteners.

Needle valve plugged.

Open needle valve, cycle markers slowly and reset

needle valve. See page 55.

Needle valve(s) in sequence valve

plugged.

Open needle valves, cycle markers slowly and reset

needle valves. See page 55.

Wing Fold Switch ON

Turn Wing Fold switch OFF

Marker disk

does not

mark

Marker folding linkage does not have

enough slack to allow marker disk to

drop into field depressions.

See “Marker Chain Length Adjustment” on page 54.

Marker disc needs adjustment

Increase disc angle. If still no mark, reverse marker disk

to pull or throw dirt.

Problem

Cause

Solution