Ultra-cut 400 xt – Tweco 400 XT Ultra-Cut Plasma Cutting System With Automated Gas Control User Manual

Page 97

ULTRA-CUT 400 XT

Manual 0-5306

OPERATION

4-29

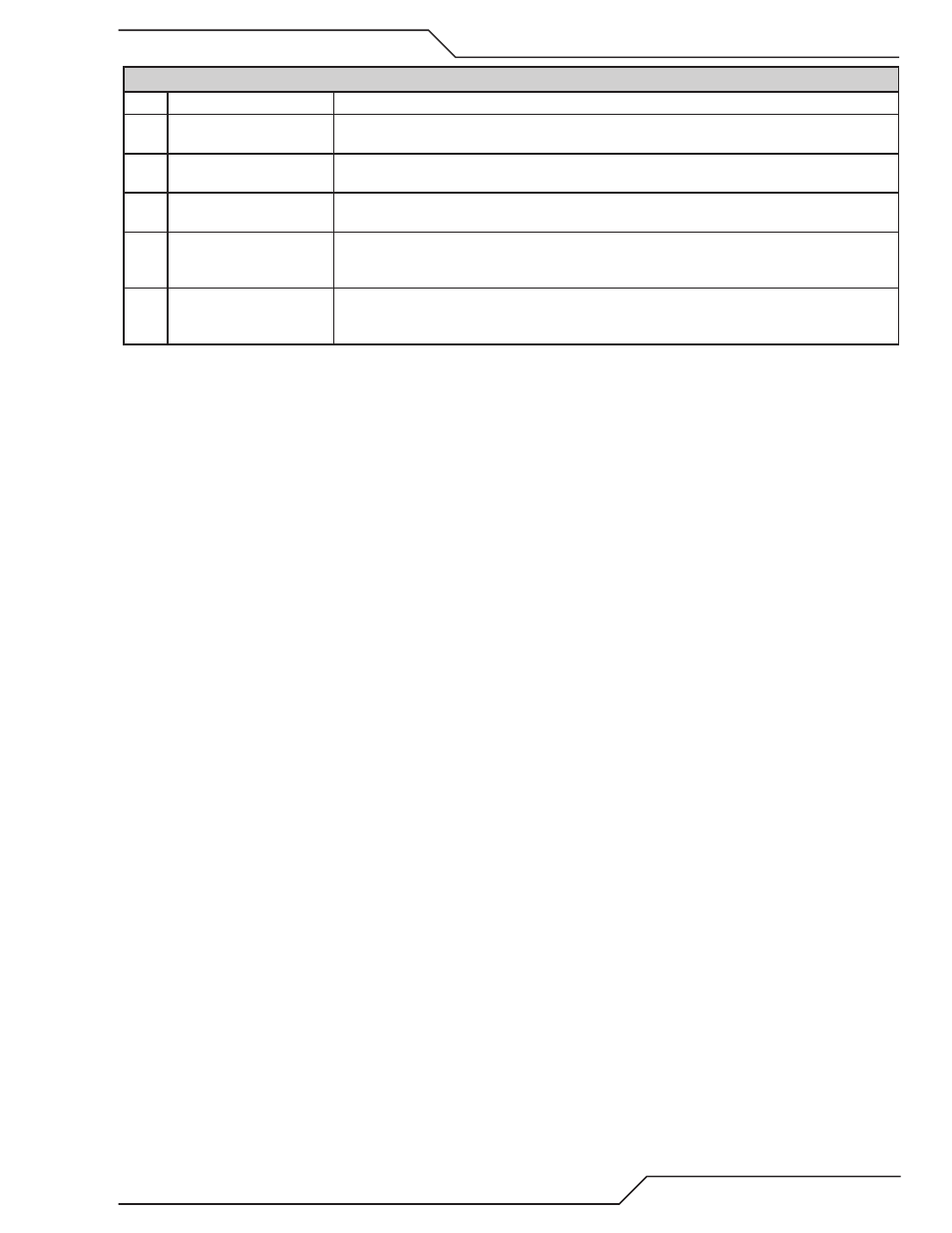

Group 9 - Shield H2O Proportional Valve (V2)

9-1

Valve open

Check for open connection; Replace valve.

9-2

DPC inlet Supply pressure

low

Raise plasma inlet pressure; check for DMC valve not open; restriction in gas supply/hoses.

9-3

Outlet flow too low

Valve full on but pressure still too low. Leak in shield hose to torch; Defective control valve (V2);

Defective pressure sensor (PS5) or flow sensor (FS-1) if equiped; DPC Control PCB

9-4

Outlet flow low

Tracking error, outlet pressure too low. Leak in shield hose to torc; Defective control valve (V2).

Defective pressure sensor (PS5) or flow sensor (FS-1) if equiped; DPC Control PCB

9-5

Outlet flow Too high

Valve set to minimum but valve outlet pressure still too high. Mineral build up or other restriction in

control valve (V2), DPC manifold, shield hose or torch; Defective control valve (V2)/ Defective pres-

sure sensor (PS5) or flow sensor (FS-1) if equiped; DPC Control PCB

9-6

Outlet flow high

Tracking error, outlet pressure too high. Mineral build up or other restriction in control valve (V2),

DPC manufold, shield hose or torch; Defective control valve (V2); Defective pressure sensor (PS5)

or flow sensor (FS-1) if equiped; DPC Control PCB