11 handling and installation of fiber optics, Handling and installation of fiber optics -10, Ultra-cut 400 xt – Tweco 400 XT Ultra-Cut Plasma Cutting System With Automated Gas Control User Manual

Page 32

ULTRA-CUT 400 XT

3-10

INSTALLATION

Manual 0-5306

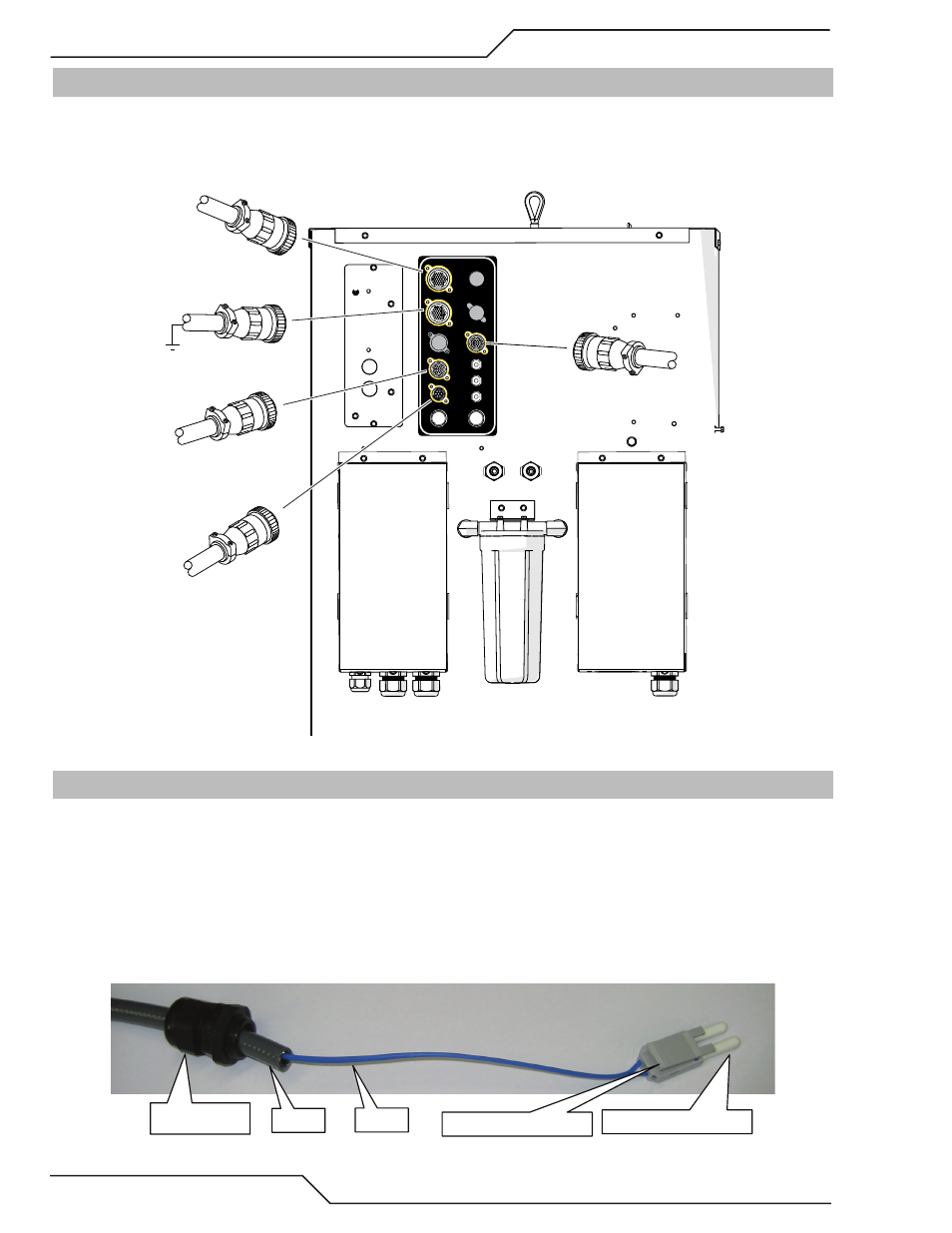

3.10 Connect Cables for CNC, Remote Arc Starter, GCM and HE 400

1. Connect one end of each cable to the power supply.

2. Connect the other end of the CNC cable to the CNC device

.

3. The CNC cable shield must be attached to ground at the CNC end.

USER INPUT

HEIGHT CONTROL

F1 - 8A SB 230 VAC

F2 - 8A SB 230 VAC

CB4 - 5A 120 VAC

CB3 - 5A 24 VAC

CB2 - 5A 120 VAC

J55 - GCM

J15 - CNC

J59 - RAS

J70 - HE

J54 - TSC /COMM

Art # A-11971

J15 To CNC Control

J59 To Remote

Arc Starter

J55 To GCM

J70 To Heat

Exchanger

J54 TSC/

Comm

3.11 Handling and Installation of Fiber Optics

General Information

This kit is for proper handling and installation of Fiber Optic Cables used in Thermal Dynamics Ultra-Cut

®

and Auto-Cut O2

®

automated gas boxes and Gas Control Modules.

Fiber Optic cable is used in place of wire because it offers far superior immunity to electrical noise but it is more delicate and

requires careful handling. With fiber optics, electrical signals are converted to light with a transmitter LED. The light passes down

the fiber where it is converted back to an electrical signal at the receiver end. Any damage to the fiber from sharp bends or pulling

that stretches the fiber can reduce it’s ability to transmit light. We run the fiber inside a hose for most of its length to protect it

from abrasion, burning from hot metal or sharp bends but the ends are exposed and must be handled with care.

Hose

Strain Relief

Fiber

Connector with Latch

Protective End Covers

Art # A-09416