Ultra-cut 400 xt – Tweco 400 XT Ultra-Cut Plasma Cutting System With Automated Gas Control User Manual

Page 129

ULTRA-CUT 400 XT

Manual 0-5306

APPENDIX

A-5

5

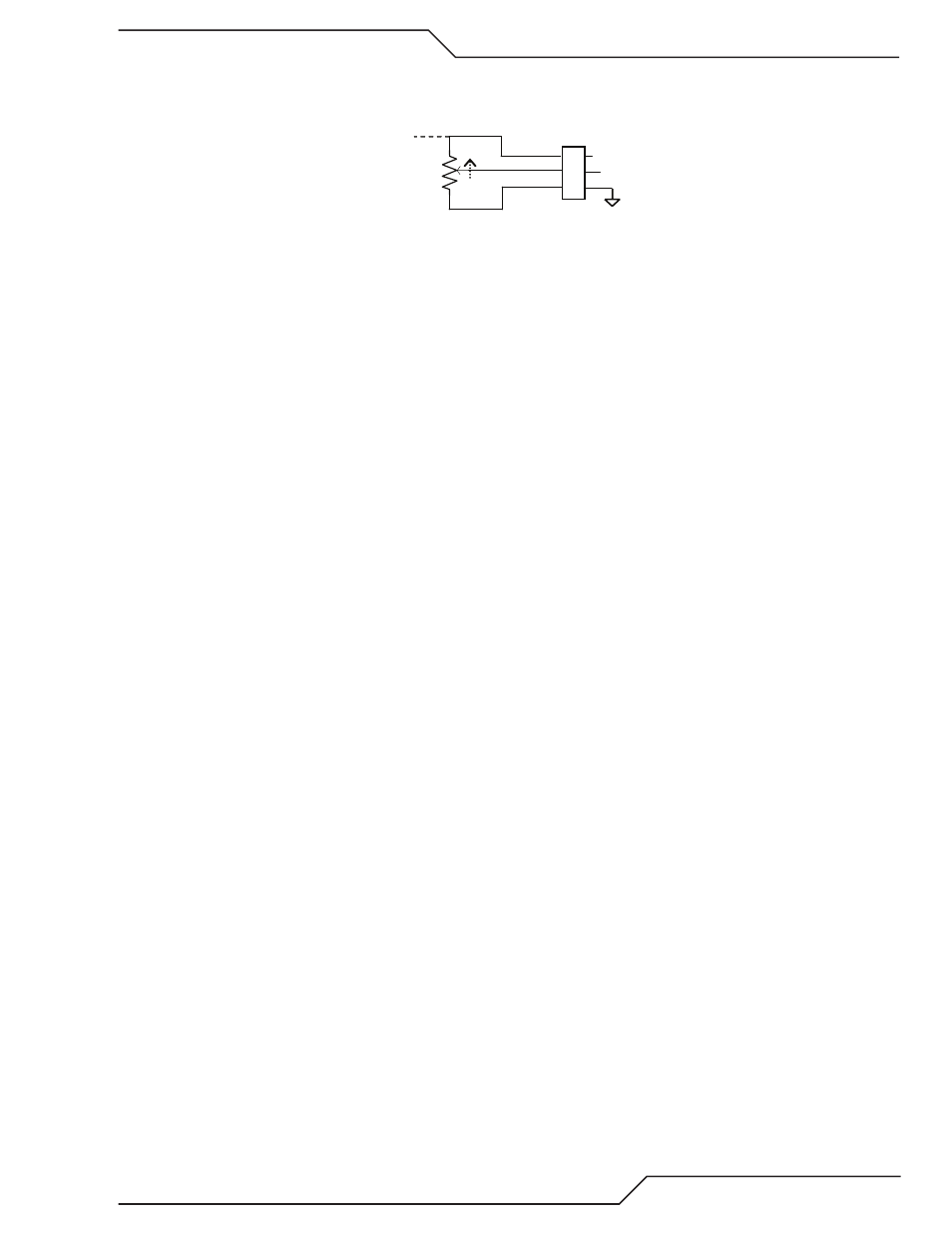

+10V @ 10ma. For Remote CC Pot – Previously CCM versions if one wanted to use a potentiometer for the Remote Analog

Current Control (CC) input an external 10 V supply was required for Pot High.. Now an isolated (from main plasma circuits) 10V

supply is provided. Recommended value of the pot is 5K or 10K.

Ext. +10V

11

10

9

TB1

+10V

WIPER

Art # A-09246

5

Plasma Marking Select (Remote) – Plasma Marking, available only with DFC 3000, may be activated with a contact closure

between TB3-1 & TB3-2 if SW8-4, DIP switch on the CPU board (smaller of the 2 CCM boards), is also on. Opening the con-

nection between TB3-1 & TB3-2 switched back to normal cutting mode. For Ultracut power supplies It is OK to leave SW8-4 on

whether you are marking or not.

The following functions may not yet be available on your system. *

*Corner Current Reduction (input)--- When activated, normally from a table controller’s corner or height control inhibit signal,

signaling that the cutting speed is being reduced to navigate a corner or small radius, the cutting current is reduced at a fixed

rate to a predetermined level to provide an improved cut at the lower speed.

*Cut Expanded Metal (input)---Normally the plasma supply is optimized for pierce cutting, high pierce height directly above

the metal to be cut, short pilot time, etc. Activating this input adjusts the plasma supply to optimize it’s parameters for cutting

expanded metal, perforated metal, running edge starting, etc. Among other changes the transfer height is reduced to same as

cut height. In addition to activating the Cut Expanded Metal input CCM switch SW1-1 should be turned on automatically restart

the pilot and SW8-1 set on for longer pilot time.

*Spare contacts --- .