Ultra-cut 400 xt – Tweco 400 XT Ultra-Cut Plasma Cutting System With Automated Gas Control User Manual

Page 63

ULTRA-CUT 400 XT

Manual 0-5306

INSTALLATION

3-41

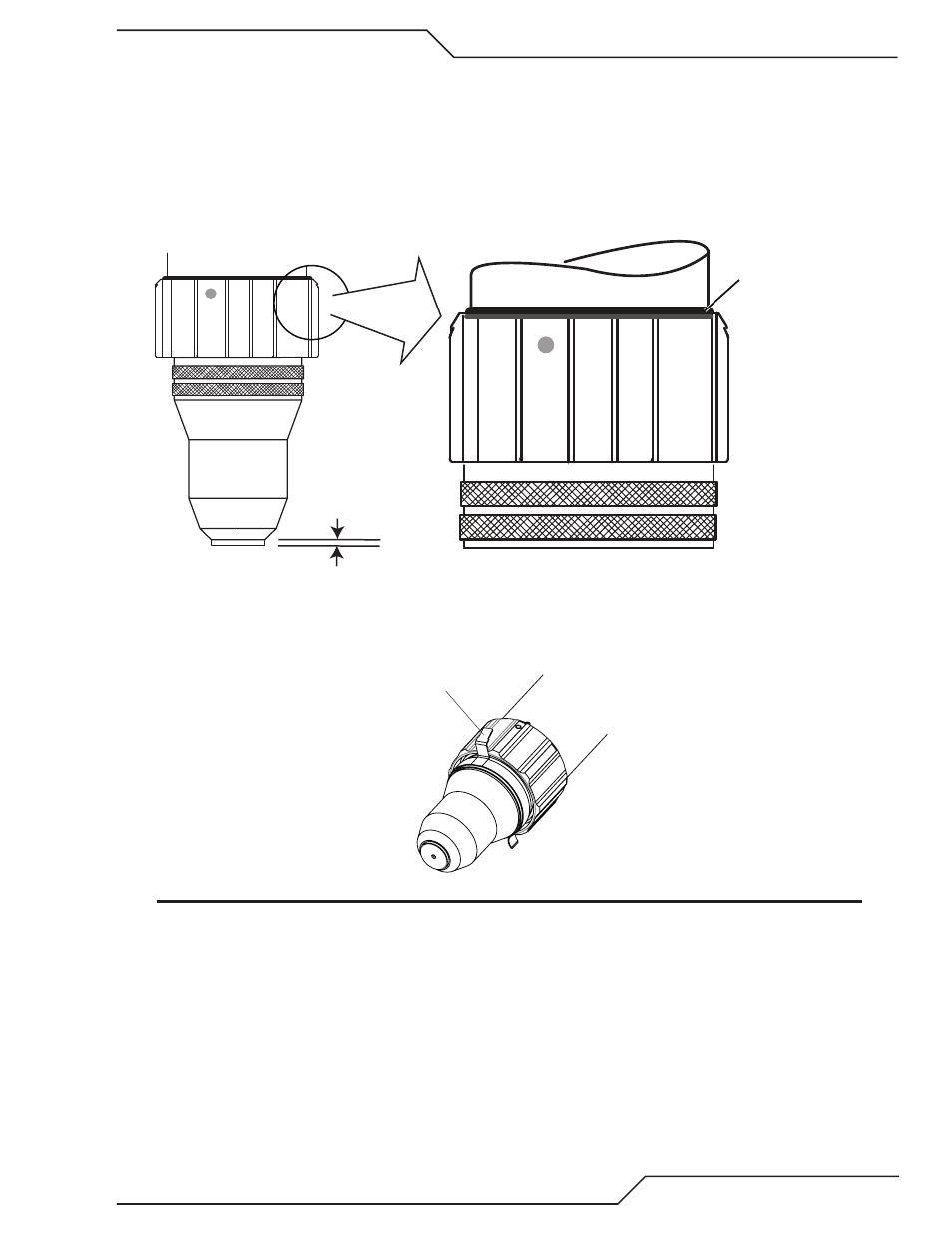

4. Insert the stack of consumable parts into the cartridge. Ensure that the large O-ring on the torch tip fits completely into

the cartridge. If any part of the O-ring protrudes from the cartridge, the parts are not seated properly.

5. Use the cartridge tool to hold the cartridge assembly, while turning the shield cup (and shield retainer for 200 Amp parts)

onto the cartridge assembly. For 300 Amp parts turn the shield retainer onto the shield cup now. When this group is

fully assembled, the shield should protrude from the front of the shield cup or shield retainer. Without this protrusion

the shield cup is not properly tightened onto the cartridge assembly.

6. Take the cartridge tool off the cartridge. Fit the cartridge assembly onto the torch head. The Speed Lok ring should click

into place and the cartridge assembly should touch the large O-ring on the torch body.

Torch Head O-Ring

Torch Head

Art # A-08300_AB

0.063 - 0.083"

(1.6 - 2.1 mm)

Protrusion

Installing Assembled Cartridge Onto Torch Head

7. Slide the ohmic clip over the shield cup if using ohmic torch height sensing.

8. Connect the wire lead from the height finder to the ohmic clip if using ohmic torch height sensing.

Ohmic Clip

Art # A-03393_AB

NOTE

Ohmic height sensing is not recommended with water shield. Water on the plate interferes electrically

with the ohmic sensing circuit.