Chapter 4 - mounting and connecting, Unpacking, handling, and inspection, Chapter 4 – Rockwell Automation MPAS Integrated Linear Stages User Manual

Page 27: Mounting and connecting, Chapter

Rockwell Automation Publication MP-UM001D-EN-P - September 2013

27

Chapter

4

Mounting and Connecting

Unpacking, Handling, and

Inspection

Inspect packaging to make certain no damage has occurred in shipment. Any

damage or suspected damage must be immediately documented. Claims for

damage due to shipment are usually made against the transportation company.

Contact Allen-Bradley immediately for further advice.

Be sure the information listed on the purchase order correlates to the information

on the packing slip for your linear stage and its accessories. Inspect the assemblies

and confirm, if applicable, the presence of specified options.

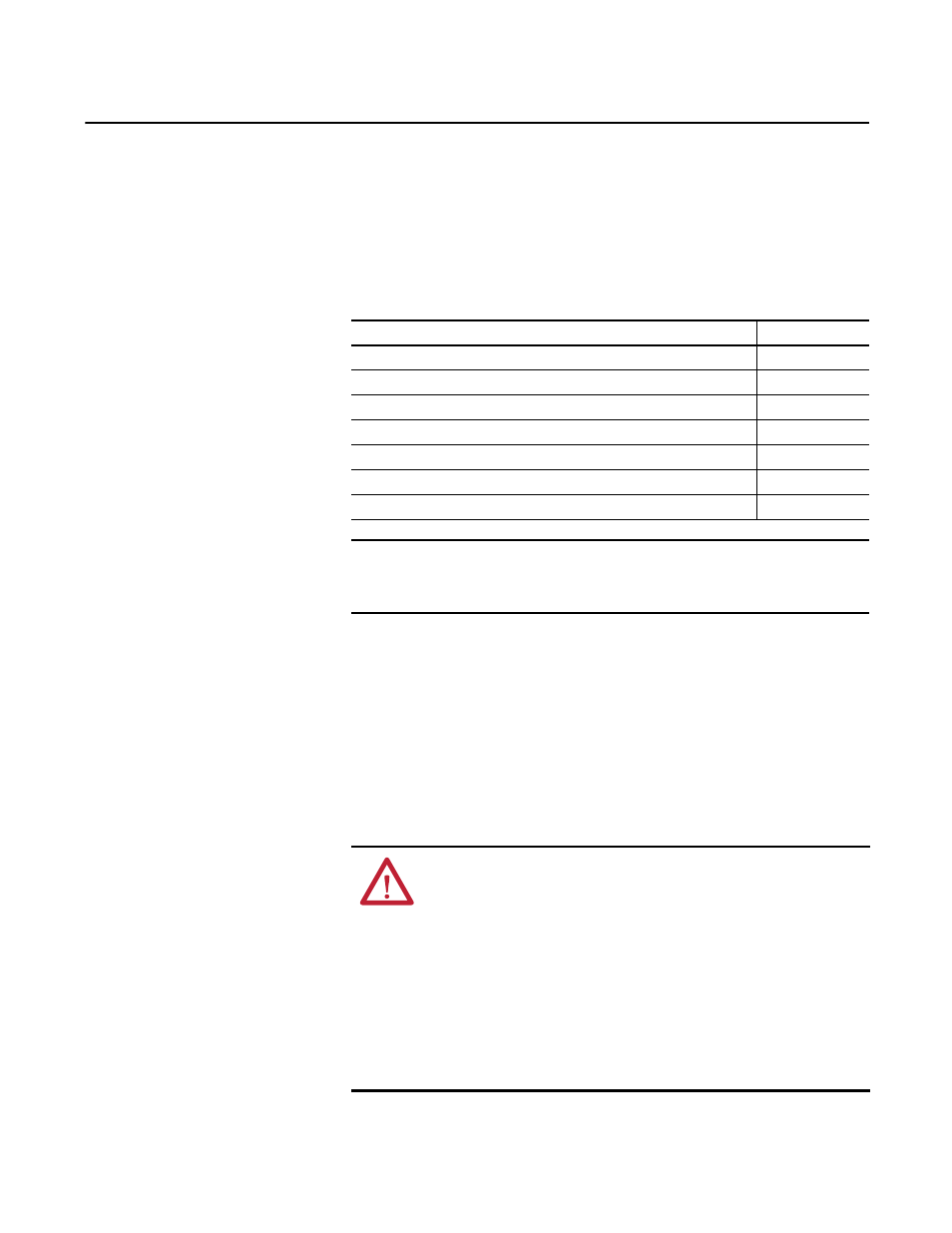

Topic

Page

Unpacking, Handling, and Inspection

About the Air Option for Ball Screw Linear Stages

About the Brake Option for Ball Screw Linear Stages

Meeting UL Installation Standards for the Linear Stage

IMPORTANT

Any person that teaches, operates, maintains, or repairs these linear stages

must be trained and demonstrate the competence to safely perform the

assigned task.

ATTENTION: Direct drive linear stages contain powerful permanent magnets

that require extreme caution during handling. Do not disassemble the linear

stage. The forces generated by permanent magnets are very powerful and can

cause bodily injury.

Persons with pacemakers or automatic implantable cardiac defibrillators

(AICD) must maintain a minimum distance of 0.3 m (12 in.) from magnet

assemblies.

Additionally, unless absolutely unavoidable, a minimum distance of 1.5 m (5 ft)

must be maintained between magnet assemblies and other magnetic or ferrous

composite materials. Calipers, micrometers, laser equipment, and other types of

instrumentation must be nonmetallic.