Bonding modules – Rockwell Automation 2090 Ultra3000 Installation Manual User Manual

Page 35

Publication 2098-IN003E-EN-P — April 2004

Installing Your Ultra3000

1-11

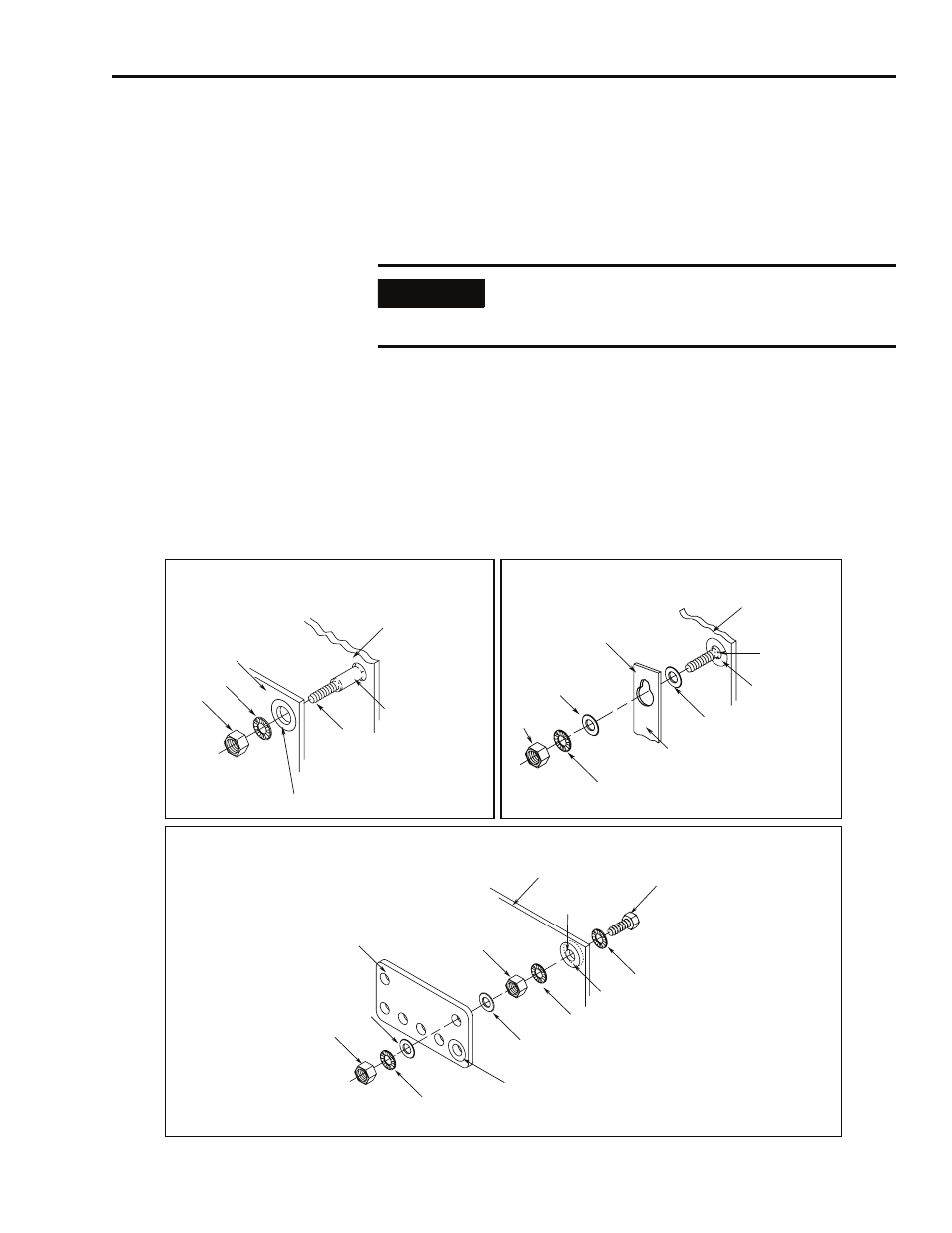

Bonding Modules

Unless specified, most paints are not conductive and they act as

insulators. To achieve a good bond between modules and the

subpanel, surfaces need to be paint-free or plated. Bonding metal

surfaces creates a low-impedance exit path for high-frequency energy.

Improper bonding blocks that direct exit path and allows

high-frequency energy to travel elsewhere in the cabinet. Excessive

high-frequency energy can effect the operation of other

microprocessor controlled equipment. The illustrations that follow

(refer to Figure 1.5) show details of recommended bonding practices

for painted panels, enclosures, and mounting brackets.

Figure 1.5

Recommended Bonding Practices

IMPORTANT

To improve the bond between the drive and

subpanel, construct your subpanel out of zinc plated

(paint-free) steel.

Stud-mounting the subpanel

to the enclosure back wall

Stud-mounting a ground bus

or chassis to the subpanel

Subpanel

Welded stud

Scrape paint

Flat washer

If the mounting bracket is coated with

a non-conductive material (anodized,

painted, etc.), scrape the material

around the mounting hole.

Star washer

Nut

Nut

Flat washer

Mounting bracket or

ground bus

Use a wire brush to remove paint from

threads to maximize ground

connection.

Back wall of

enclosure

Welded

stud

Subpanel

Star washer

Use plated panels or scrape paint on

front of panel.

Subpanel

Nut

Nut

Star washer

Flat washer

Star washer

Star washer

Scrape paint on both sides of

panel and use star washers.

Tapped hole

Bolt

Flat washer

Ground bus or

mounting bracket

If the mounting bracket is coated with

a non-conductive material (anodized,

painted, etc.), scrape the material

around the mounting hole.

Bolt-mounting a ground bus or chassis to the back-panel