Rockwell Automation 160 AC DRIVE SER B/FRN 5-6.XX User Manual

Page 42

Chapter 6 – Troubleshooting and Fault Information

6-3

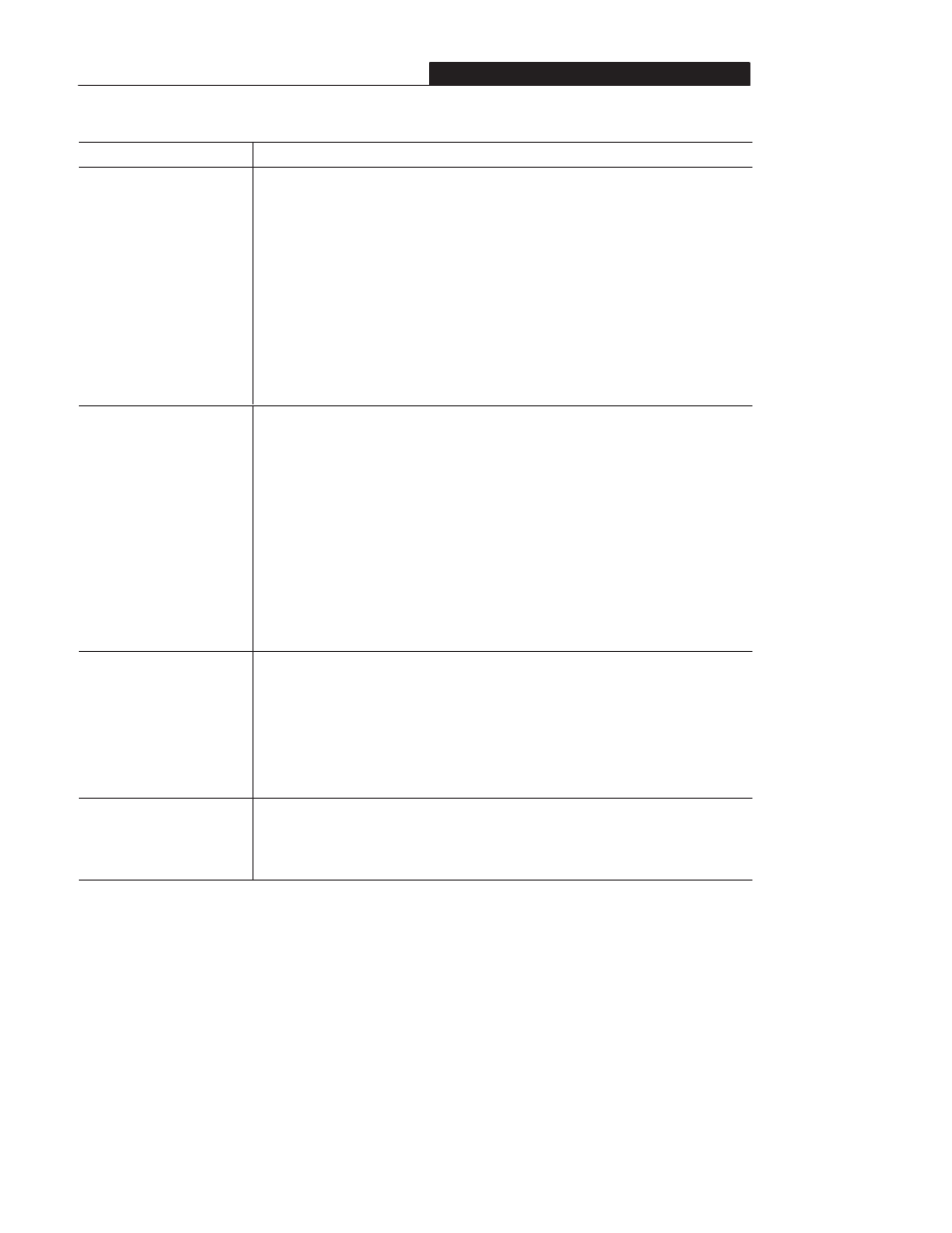

Table 6.B – Troubleshooting

Problem

Corrective Action

Motor does not start

(No output voltage to motor).

1. Check power circuit.

S Check supply voltage.

S Check all fuses and disconnects.

2. Check motor.

S Verify that motor is connected properly.

3. Check control input signals.

S Verify that START signal is present.

S Verify that STOP signal is present.

S Verify that RUN FORWARD and RUN REVERSE signals are NOT both active.

4. Check

P46 – [Input Mode]

.

S If P46 – [Input Mode] is set to “2”, only the program keypad module

Start

button will start the

motor.

Controller Started but motor

NOT rotating.

(P01 – [Output Frequency]

displays “0.0”).

1. Check motor.

S Verify that motor is connected properly.

2. Check frequency source

P06 – [Frequency Command

].

S Verify that frequency signal is present at terminal block TB3.

S –10- +10V signal

S 4–20mA signal

S Verify that Preset Frequencies are set properly.

3. Check control input signals.

S Verify that SW1, SW2 and SW3 are correct. (Refer to the chart at the end of Chapter 5).

4. Check parameter settings.

S Verify that

P59 – [Frequency Select]

is showing desired frequency source.

S Verify that

P58 – [Internal Frequency]

is the desired value.

Motor not accelerating properly.

1. Check motor.

S Verify that motor is connected properly.

S Verify that no mechanical problems exist.

2. Check parameter settings.

S Verify that

P30 – [Accel Time 1]

or

P69 – [Accel Time 2]

is set properly.

S Verify that

P43 – [Current Limit]

is set properly.

S Verify that

P38 – [Boost Volts

] is set properly.

Can not operate in “RUN FWD/

RUN REV” mode.

1. Verify that P46 – [Input Mode] is set to “1”.

2. Verify that P73 – [Reverse Disable] or P74 – [Analog Select] are not set to “1”.

3. Verify that power has been cycled for above change to take effect.

4. Verify that both RUN FORWARD and RUN REVERSE switches are NOT closed simultaneously.