Program group, 71 [ir compensation, 72 [slip compensation – Rockwell Automation 160 AC DRIVE SER B/FRN 5-6.XX User Manual

Page 39: 73 [reverse disable, 74 [analog select, 75 [analog input minimum, 76 [analog input maximum, 78 [compensation

Chapter 5 – Parameters and Programming

5-12

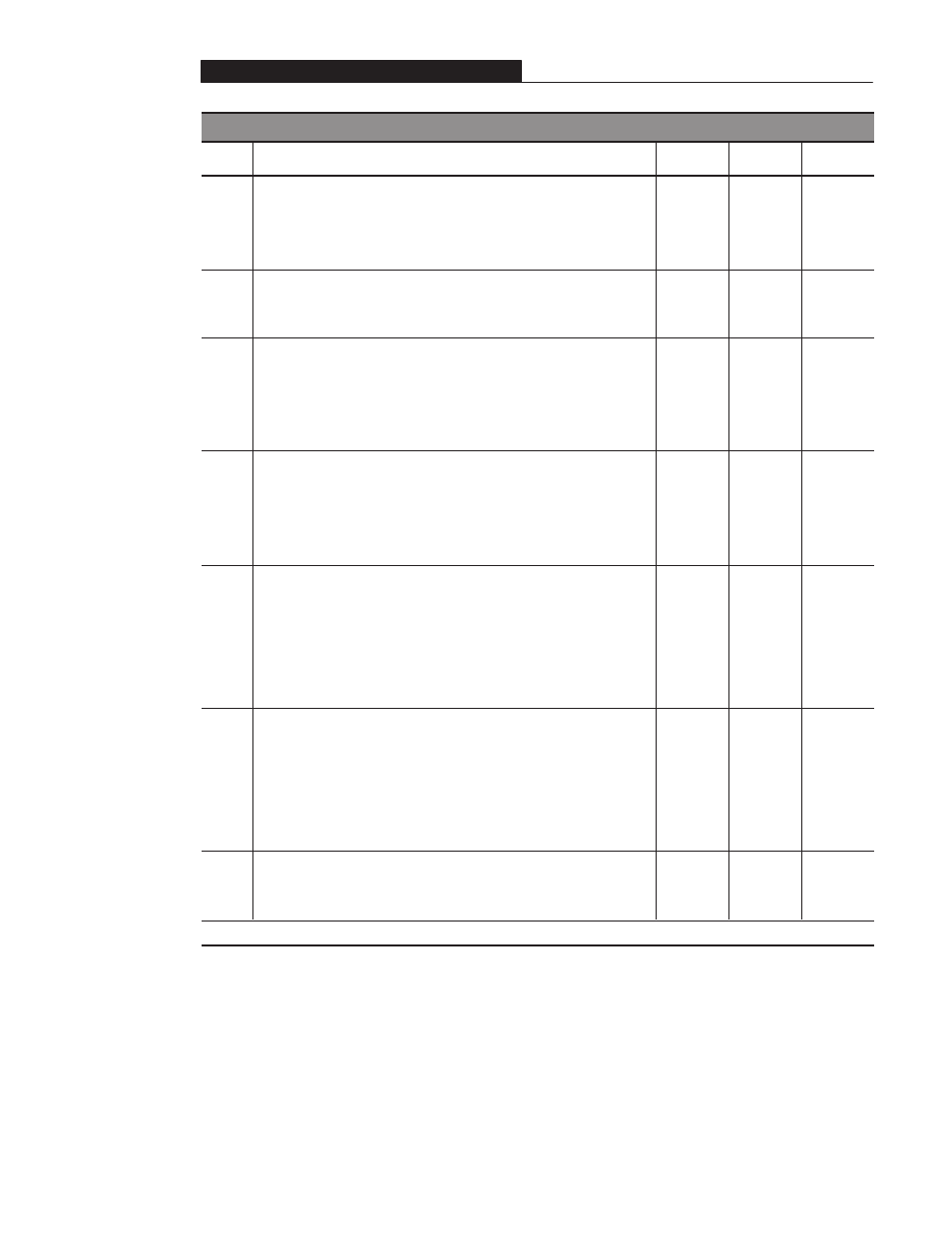

Program Group

P#

Parameter Description

Min/Max

Range

Units

Factory

Default

71

[IR Compensation]

The programmed value adds a voltage to the

output based on the torque current. An additional 31 volts (150%) are added to

460 volt units to compensate for stator resistance. 15.5 volts (150%) is added for

230 volt units. If the drive trips on an Overload fault (F7), or has trouble

accelerating to commanded speed, this value should be reduced. A setting of 0%

disables this function.

0 to 150

1%

50%

72

[Slip Compensation]

This parameter compensates for the inherent slip in an

induction motor. A frequency is added to the commanded output frequency based on

torque current. If motor shaft speed decreases significantly under heavy loads then this

value should be increased. A setting of 0.0 Hz disables the function.

0.0 to 5.0

0.1 Hz

2.0 Hz

73

[Reverse Disable]

When this parameter is set to a 1, the reverse is

disabled. The reverse command may come from the analog input, the TB3-5 input, the

keypad, or a serial command. With a negative analog input and reverse disabled, the

frequency command will be zero in bipolar mode and minimum frequency in unipolar

mode. All digital reverse inputs including two-wire “Run Reverse” will be ignored with

reverse disabled.

Important:

This parameter cannot be programmed while the drive is running.

0 to 1

Numeric

value

0

ЙЙЙ

Й

Й

Й

Й

Й

Й

Й

Й

Й

Й

Й

Й

ЙЙЙ

74

[Analog Select]

0 = unipolar analog input 0 to +10V

1 = bipolar analog input –10 to +10V

Important:

With bipolar analog input selected, the reverse inputs (keypad, terminal

block, serial) are ignored. In addition, two-wire “Run Reverse” commands, P75 –

[Analog Input Minimum] and P32 – [Minimum Frequency] settings are ignored.

Important:

This parameter cannot be programmed while the drive is running.

0 to 1

Numeric

value

0

ЙЙЙ

Й

Й

Й

Й

Й

Й

Й

Й

Й

Й

Й

Й

Й

Й

Й

ЙЙЙ

75

[Analog Input Minimum]

Important:

Do not adjust this parameter until setting P60 – [Zero Offset].

Sets the percent of analog input used to represent P32 – [Minimum Frequency]. If

the minimum analog input equals minimum frequency no action is needed. If it is

desired to adjust the analog input to equal [Minimum Frequency], use

P16 – [Analog Input] to adjust the analog input to the desired level and then enter

this value into P75.

Analog inversion can be accomplished by setting this value larger than P76.

Important:

This parameter cannot be programmed while the drive is running.

0.0 to 150.0

0.1%

0.0%

ЙЙЙ

Й

Й

Й

Й

Й

Й

Й

Й

Й

Й

Й

Й

Й

Й

Й

ЙЙЙ

76

[Analog Input Maximum]

Important:

Do not adjust this parameter until setting P60 – [Zero Offset].

Sets the percent of analog input used to represent P33 – [Maximum Frequency]. If

the maximum analog input equals maximum frequency no action is needed. If it is

desired to adjust the analog input to equal [Maximum Frequency], use

P16 – [Analog Input] to adjust the analog input to the desired level and then enter

this value into P76.

Analog inversion can be accomplished by setting this value smaller than P75.

Important:

This parameter cannot be programmed while the drive is running.

0.0 to 150.0

0.1%

100.0%

78

[Compensation]

Some drive/motor combinations have inherent instabilities

which are exhibited as non-sinusoidal motor currents. A setting of 1 will enable this

parameter and attempt to correct this condition. A setting of 0 disables this function.

Important:

Available in FRN 6.XX and later.

0 to 1

Numeric

value

0

ЙЙЙ

ЙЙЙ

=

This parameter applies only to the Analog Signal Follower model.