Motor cable recommendations, Long motor cable effects – Rockwell Automation 160 AC DRIVE SER B/FRN 5-6.XX User Manual

Page 17

Chapter 2 – Installation and Wiring

2-4

Motor Cable Recommendations

A variety of cable types are acceptable for

variable speed controller installations. For many

installations, unshielded cable is adequate,

provided it can be separated from sensitive

circuits. As an approximate guide, allow a

spacing of 1 meter (3.3 feet) for every 10 meters

(33 feet) of unshielded length. If you cannot

separate motor cables from sensitive circuits, or if

you must run motor cables from multiple

controllers (more than three) in a common

conduit or cable trays, shielded motor cable is

recommended to reduce system noise.

Motor cables should be four-conductor with the

ground lead and shield (if using shielded cable)

connected to the controller ground terminal and

the motor frame ground terminal.

Table 2.E provides the recommended wire type

for both wet and dry installations as defined by

NEC 1996 (70-31). These recommendations are

based upon a variety of factors such as insulation

thickness, susceptibility to moisture and

susceptibility to nicks and cuts during installation.

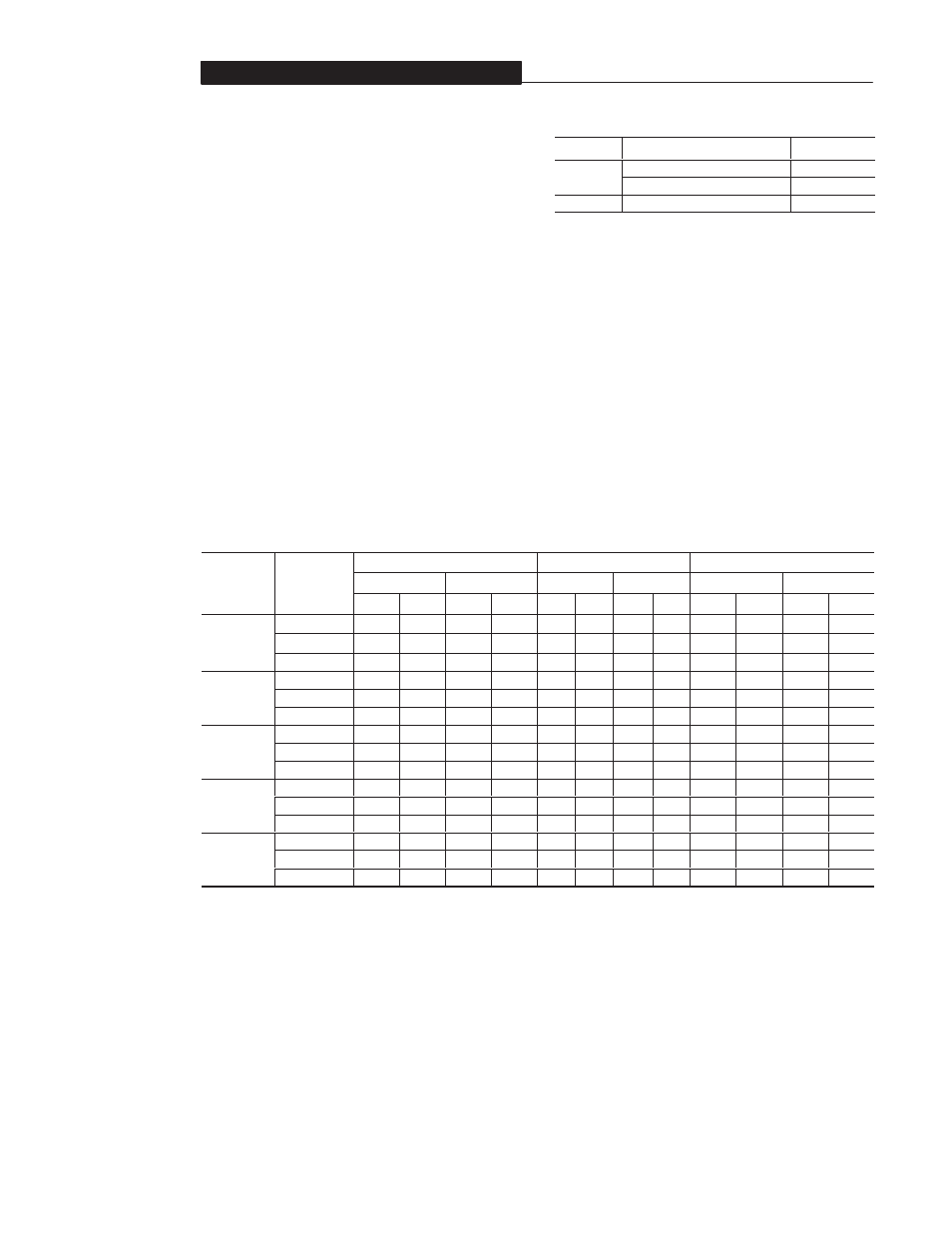

Table 2.E – Recommended Cable Type(s)

Condition

Insulation Type(s)

Example(s)

Dry

PVC

①

THHN

Dry

XLPE

XHHW-2

Wet

XLPE

XHHW-2

➀

For AC line voltages in excess of 264V AC, or motor cable

distances greater than 50 ft (15m), wire with XLPE insulation is

recommended.

Long Motor Cable Effects

The controller should be installed as close to the

motor whenever possible. Installation with long

motor cables may require the addition of external

devices to limit voltage reflections at the motor

(reflected wave phenomona). See Table 2.F for

recommendations.

Important: The use of an external device to limit

reflected wave issues may effect the accuracy of

the Bulletin 160 current sensing. Table 2.G

provides recommended cable length due to

Capacitive Current considerations.

Table 2.F – Cable Length Recommendations — Reflected Wave

➁

380

460V

Motor

Motor Cable Only

RWR at Drive

③

Reactor at Motor

380 – 460V

Ratings

Motor

Insulation

at n

Shielded

Unshielded

Shielded

Unshielded

Shielded

Unshielded

Ratings

Insulat on

Rating

ft.

m.

ft.

m.

ft.

m.

ft.

m.

ft.

m.

ft.

m.

2 2 kW

1000 Vp-p

40

12

40

12

360

110

300

92

210

64

210

64

2.2 kW

(3 HP)

1200 Vp-p

60

18

60

18

360

110

600

183

260

79

260

79

(3 HP)

1600 Vp-p

500

➃

152

➃

500

➃

152

➃

360

110

600

183

500

➃

152

➃

500

➃

152

➃

1 5kW

1000 Vp-p

40

12

40

12

300

92

300

92

250

76

250

76

1.5kW

(2 HP)

1200 Vp-p

60

18

60

18

300

92

540

165

340

104

340

104

(2 HP)

1600 Vp-p

500

➃

152

➃

500

➃

152

➃

300

92

540

165

500

➃

152

➃

500

➃

152

➃

0 75 kW

1000 Vp-p

55

17

40

12

300

92

300

92

325

99

325

99

0.75 kW

(1 HP)

1200 Vp-p

125

43

60

18

300

92

375

114

500

152

325

99

(1 HP)

1600 Vp-p

500

➃

152

➃

500

➃

152

➃

300

92

375

114

500

➃

152

➃

500

➃

152

➃

0 55 kW

1000 Vp-p

45

14

40

12

300

92

300

92

300

92

300

92

0.55 kW

(0 75 HP)

1200 Vp-p

125

38

60

18

300

92

375

114

500

152

500

152

(0.75 HP)

1600 Vp-p

500

➃

152

➃

500

➃

152

➃

300

92

375

114

500

➃

152

➃

500

➃

152

➃

0 37 kW

1000 Vp-p

45

14

40

12

300

92

300

92

300

92

300

92

0.37 kW

(0 5 HP)

1200 Vp-p

125

38

50

15

300

92

375

114

500

152

500

152

(0.5 HP)

1600 Vp-p

500

➃

152

➃

500

➃

152

➃

300

92

375

114

500

➃

152

➃

500

➃

152

➃

➁

The reflected wave data applies to all PWM frequencies 2 to 8 kHz. For 230V ratings see Table 2.G.

➂

Cable lengths listed are for PWM frequencies of 2 kHz. Refer to publication 1204-5.1 for cable length recommendations at other PWM frequencies.

➃

The maximum peak-to-peak voltage of the controller is 1400V due to the minimum on/off time software. Reflective Wave Testing has been

done on cable lengths up to 500 feet. See Table 2.G for Capacitive Current Considerations.