Control wiring – Rockwell Automation 160 AC DRIVE SER B/FRN 5-6.XX User Manual

Page 20

Chapter 2 – Installation and Wiring

2-7

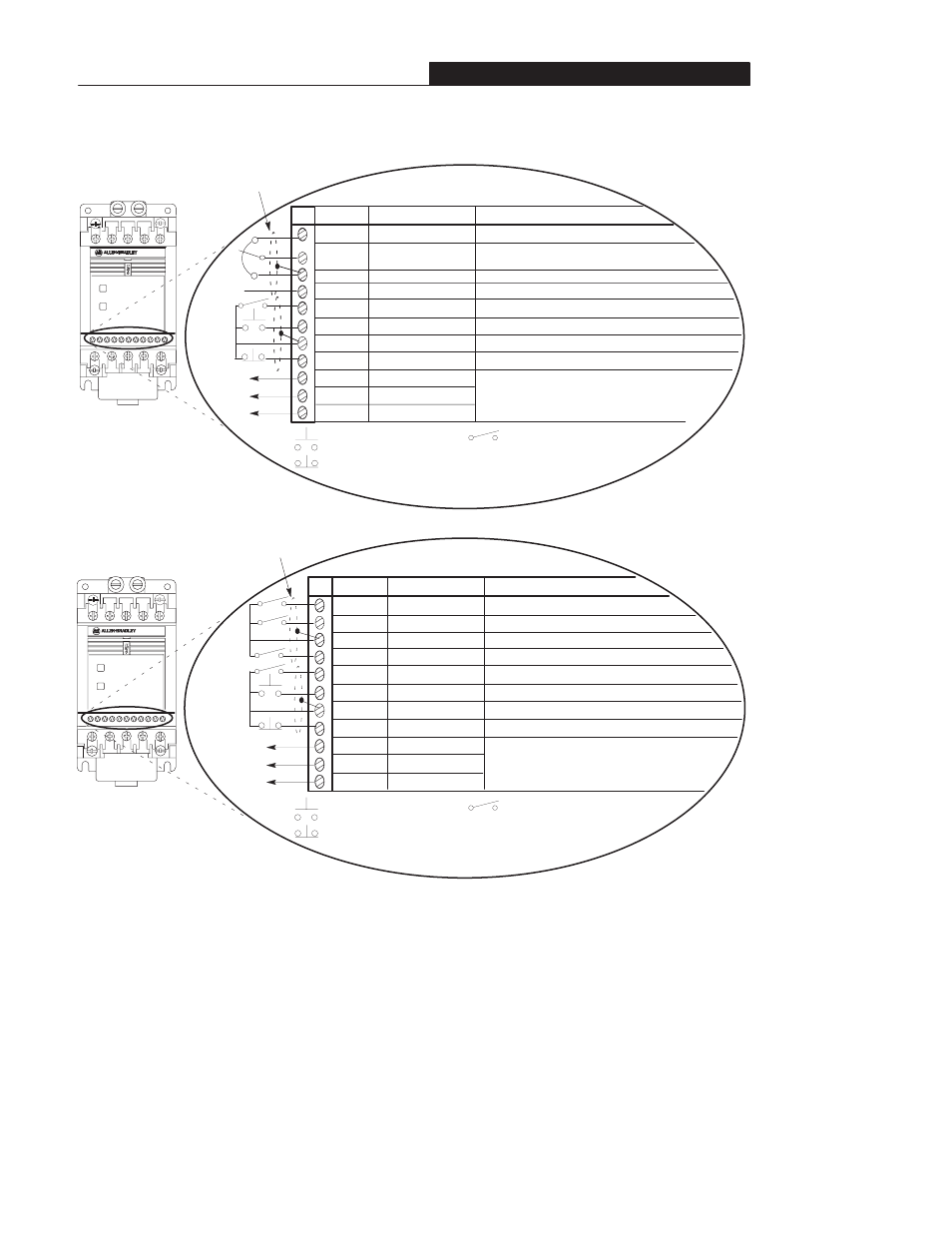

Control Wiring

8

7

6

5

4

3

2

1

9

1

10

1

+ 10V Pot

Pot Wiper or

+10/–10V DC Input

Common

4–20mA Input

Reverse

Start

Common

Stop

Normally Closed

Relay Common

Normally Open

Signal

Specification

10 k

Ω

Potentiometer, 2 Watts

Controller Input Impedance = 100 k

Ω

Controller Input Impedance = 250

Ω

Contact closure input required to operate controller

➀

Contact closure input

➀

Contact closure input

➀

Terminal

TB3

Customer-programmable relay outputs.

Resistive load 0.4A at 125V AC 2A at 30V DC.

Inductive load 0.2 A at 125V AC 1A at 30V DC.

FAULT

READY

Figure 2.3 – TB3 Control Wiring for Analog Signal Follower Model

FAULT

READY

8

7

6

5

4

3

2

1

9

1

10

1

SW1

SW2

Common

SW3

Reverse

Start

Common

Stop

Normally Closed

Relay Common

Normally Open

Signal

Specification

Contact closure input

➀

➀

Internal 12V supply.

Contact closure input

➀

Contact closure input

➀

Contact closure input required to operate controller

➀

Contact closure input

➀

Contact closure input

➀

Terminal

TB3

Customer-programmable relay outputs.

Resistive load 0.4A at 125V AC 2A at 30V DC.

Inductive load 0.2 A at 125V AC 1A at 30V DC.

Shielded Wire

Figure 2.4 – TB3 Control Wiring for Preset Speed Model

➁

Do not exceed control wiring length of 15 meters (50 feet)

.

Control signal cable length is highly dependent on

electrical environment and installation practices. To improve noise immunity the control terminal block common

must be connected to earth ground.

➂

This diagram shows “three wire” control. Refer to the following page for diagrams of other control wiring methods.

Common

➁

Common

➁

Shielded Wire

➂

➂

= N.O. Maintained Contact

= N.C. Momentary Contact

= N.O. Momentary Contact

Common

➁

= N.O. Maintained Contact

= N.C. Momentary Contact

= N.O. Momentary Contact

Common

➁