Schroth Racing All models - Competition Instructions User Manual

Page 21

T

IGHTENING

T

ORQUES BY

B

OLT

D

IMENSION

• Each bolt diameter and type of thread requires an individual torque

for proper tightening. These torques as listed below are defined by

national or international standardisation organisations.

• For safe installation always tighten bolts to the recommended torque.

• For any installation use e.g. “Loctite 243” or spring washers where

recommended to secure bolt fastening.

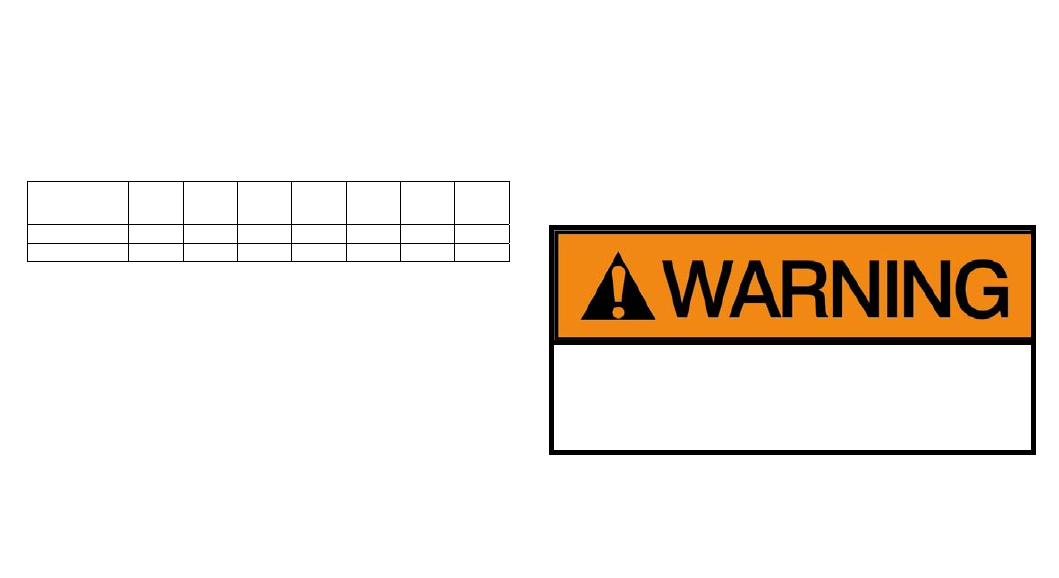

M 8

5/16” M

10 3/8”

7/16”

20 UNF 15/32”

1/2”

Torque in Nm

25 25 50 50 40 87 113

Torque in ft-lb

18,5 18,5 37 37 30 64,5 83,5

C

REATING A NEW ATTACHMENT POINT

• Follow the recommendations for geometry and strap routing

described on Pages 24

to 26 to define the proper anchor point

location.

• FIA does not allow welding or drilling to roll cages, except those

conducted and certified by the roll cage manufacturer. Only

manufacturer specified roll cage bars must be used for racing harness

installation.

• For new attachment points to the chassis heed the following

WARNING box.

If you intend to drill a hole, make sure not to damage the fuel

tank, fuel lines, electrical wires, brake lines or other important

components. Any damage to such components can result in

fire, explosion or mechanical failure and severe injuries or death

can result.

• For new attachment points to the chassis you must use a FIA specified

reinforcement plate [see “Accessories & Spare Parts”].

• Drill a hole of 12 mm [15/32”] diameter for lap- & shoulder belt and

standard anti-sub strap attachments.

- 20 -