O-ring face seal (orfs) hydraulic fittings – MacDon PW8 Pick-Up Header User Manual

Page 92

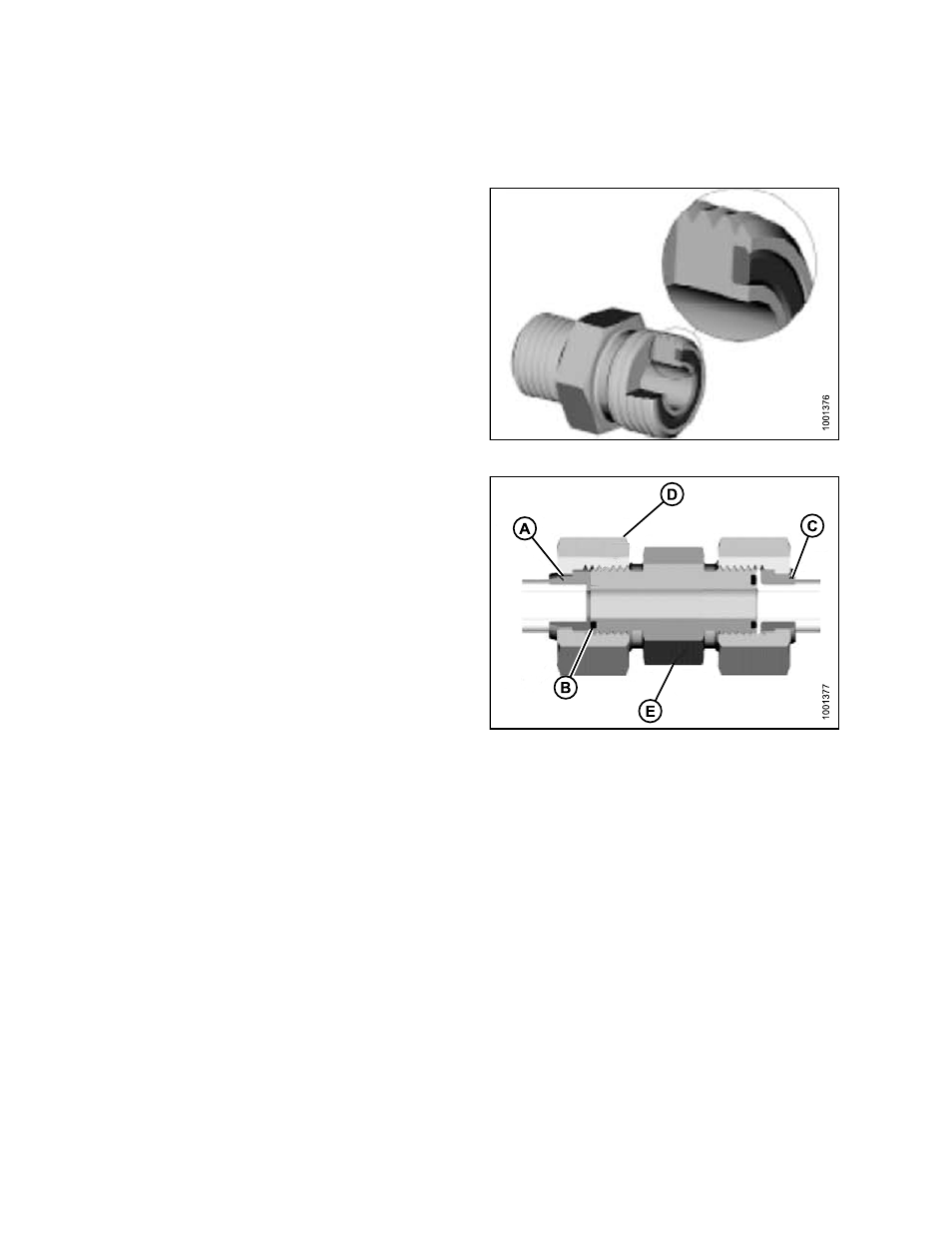

O-Ring Face Seal (ORFS) Hydraulic Fittings

To tighten O-ring face seal (ORFS) hydraulic fittings, follow these steps:

1. Check components to ensure that the sealing surfaces

and fitting threads are free of burrs, nicks, and

scratches or any foreign material.

Figure 4.7

2. Apply hydraulic system oil to the O-ring (B).

3. Align the tube or hose assembly so that the flat face

of the sleeve (A) or (C) comes in full contact with

O-ring (B).

4. Thread tube or hose nut (D) until hand-tight. The nut

should turn freely until it is bottomed out.

5. Torque fitting further to the torque value in the table

shown in the opposite column.

NOTE:

If applicable, hold the hex on the fitting body (E)

to prevent rotation of fitting body and hose when

tightening the fitting nut (D).

6. When assembling unions or two hoses together, three

wrenches will be required.

7. Check the final condition of the fitting.

Figure 4.8

A - Brazed Sleeve

B - O-ring

C - Two Piece Sleeve

D - Nut

E - Fitting Body

169489

84

Revision A