Removing drive sprocket, Danger – MacDon PW8 Pick-Up Header User Manual

Page 127

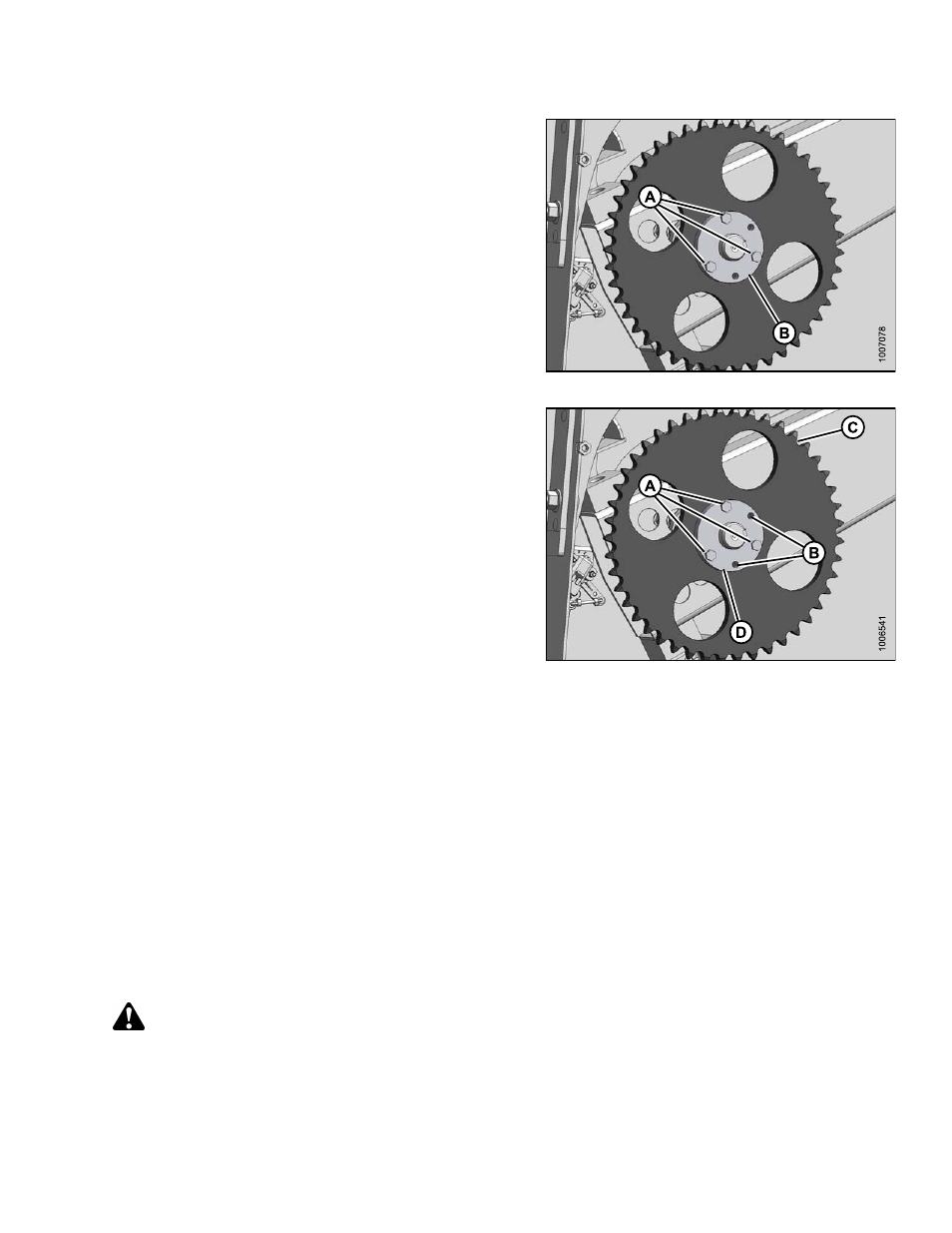

7. Tighten the three hex bolts (A) in equal increments to

32 lbf·ft (44 N·m), maintaining sprocket alignment.

8. Tap bushing (B) with a hammer, and retorque.

Repeat three times or until bolts no longer turn at

32 lbf·ft (44 N·m).

Figure 4.73

9. Check alignment of sprockets. If misalignment is more

than 0.04 in. (1 mm), measure, record amount and

proceed as follows:

a. Measure and record the position of the tapered

bushing relative to the driveshaft.

b. Remove the three hex bolts (A) from tapered

bushing.

c. Reinstall twp of the bolts (A) into the threaded

holes (B) in the tapered bushing (D).

d. Turn bolts into tapered bushing equal amounts in

half-turn increments, until the tapered bushing (D)

and sprocket (C) can be moved.

e. Reposition the tapered bushing, accounting for the

misalignment.

f.

Repeat Steps:

5., Installing Driven Sprocket, page

to

9., Installing Driven Sprocket, page 119

above.

g. Check alignment of sprockets.

h. Repeat substeps a. to g. until specified alignment

is achieved.

10. Install and tension chain. Refer to

.

11. Close endshield. Refer to

Figure 4.74

Removing Drive Sprocket

DANGER

Stop engine and remove key from ignition before leaving operator’s seat for any reason. A child or even

a pet could engage an idling machine.

169489

119

Revision A