5hydraulic safety, Hydraulic safety, 5 hydraulic safety – MacDon PW8 Pick-Up Header User Manual

Page 14

1.5

Hydraulic Safety

• Always place all hydraulic controls in Neutral before

dismounting.

• Make sure that all components in the hydraulic system

are kept in good condition and clean.

• Replace any worn, cut, abraded, flattened, or crimped

hoses and steel lines.

• Do not attempt any makeshift repairs to the hydraulic

lines, fittings, or hoses by using tapes, clamps, cements,

or welding.

The hydraulic system operates under

extremely high pressure. Such makeshift repairs will fail

suddenly and create a hazardous and unsafe condition.

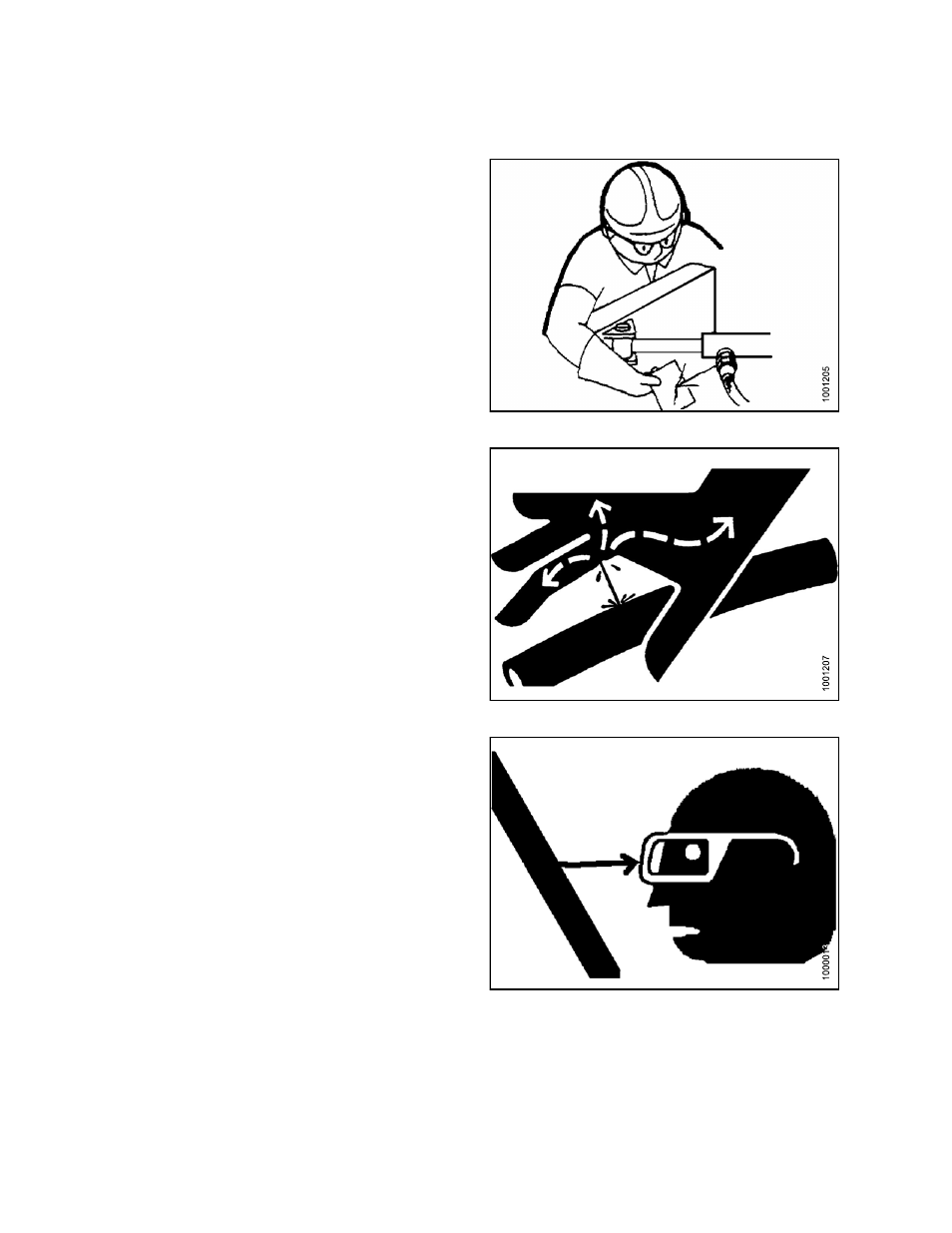

Figure 1.11: Checking Hydraulic Leaks

• Wear proper hand and eye protection when searching for

a high-pressure hydraulic leak. Use a piece of cardboard

as a backstop instead of hands to isolate and identify

a leak.

• If injured by a concentrated high-pressure stream of

hydraulic fluid, seek medical attention immediately.

Serious infection or toxic reaction can develop from

hydraulic fluid piercing the skin.

Figure 1.12: Hydraulic Pressure Hazard

• Before applying pressure to a hydraulic system, make

sure all components are tight and that steel lines, hoses,

and couplings are in good condition.

Figure 1.13: Wear Safety Glasses

169489

6

Revision A