9tcf power wiring diagram – Lenze TCF Series User Manual

Page 19

9

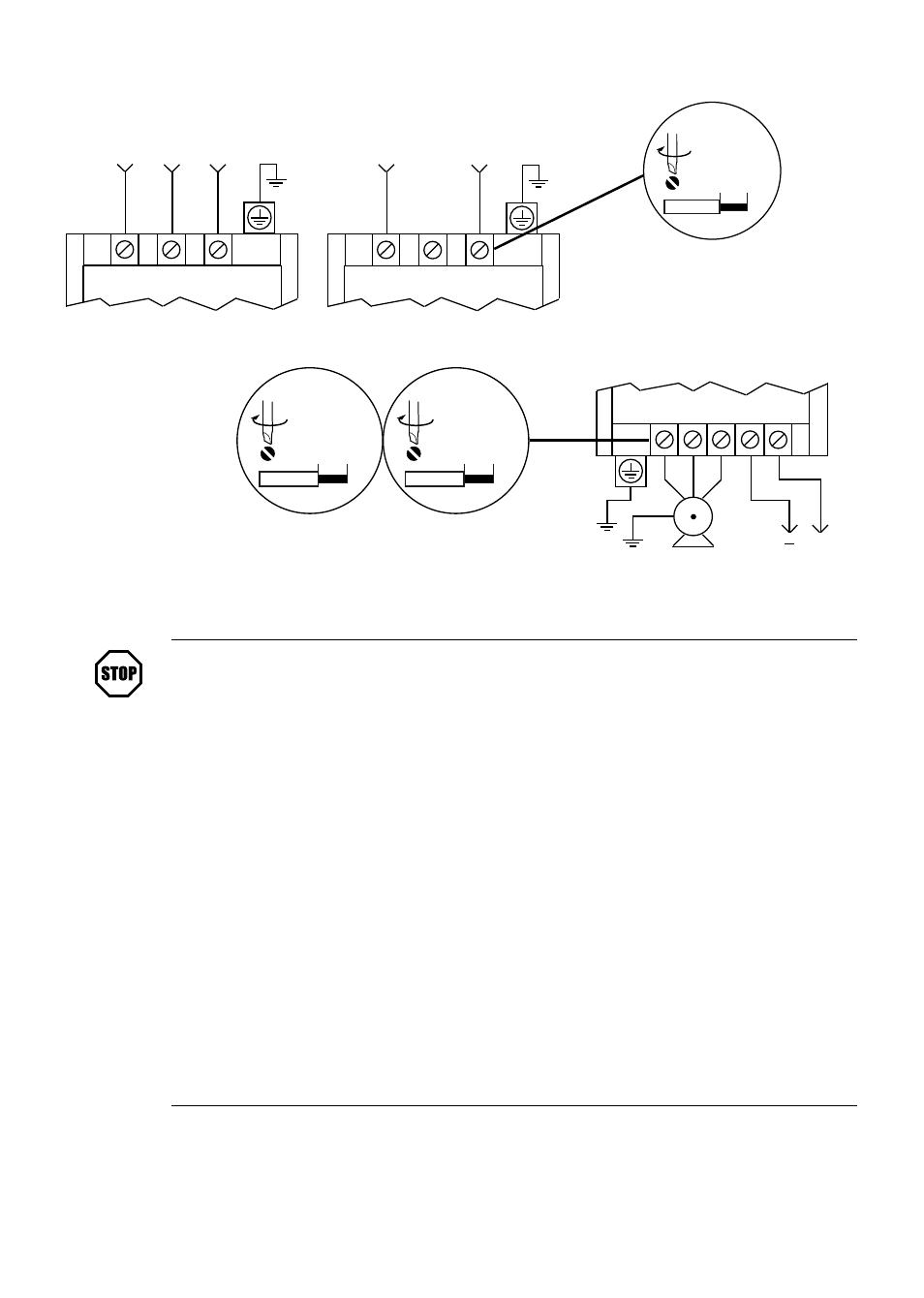

TCF POWER WIRING DIAGRAM

THREE PHASE INPUT

(ALL SERIES)

L1

L2

L3

OUTPUT (ALL SERIES)

3 PHASE

AC MOTOR

DC BUS

VOLTAGE

T1 T2 T3 B- B+

+

SINGLE PHASE INPUT

(TF200Y SERIES)

L1

L2

L3

For all other models,

use output torque values .

TF230Y &

TF250 only

7 .0 lb-in / 0 .8 Nm

0 .24 in / 6 mm

0 .5 - 5 HP

(0 .37 - 3 .7 kW)

4 .5 lb-in / 0 .5 Nm

0 .24 in / 6 mm

7 .5 - 10 HP

(5 .5 - 7 .5 kW)

10 lb-in / 1 .2 Nm

0 .35 in / 9 mm

STOP!

•

Do NOT connect AC line power to output terminals T1, T2, or T3 . Severe

damage to the drive will result .

•

Leakage current may exceed 3 .5 mA AC . Minimum size of the protective

earth conductor shall comply with local safety regulations for high leakage

current equipment .

•

Wire and Ground in accordance with NEC or CEC, and all applicable

local codes .

•

Motor wires MUST be run in a separate steel conduit away from control

wiring and incoming AC power wiring .

•

Do not install contactors between the drive and the motor without

consulting Lenze-AC Tech for more information . Failure to do so may

result in drive damage .

•

Use only UL and CSA listed and approved wire .

•

Minimum wire voltage rating is 300 V for 120, 208, and 240 Vac systems,

and 600 V for 400 and 480 Vac systems .

•

Wire gauge must be based on a minimum of 125% of the rated input/

output current of the drive, and a minimum 75°C insulation rating . Use

copper wire only .

15