14 implemented cip™ objects – Lenze E84Dxxxx User Manual

Page 116

14

Implemented CIP™ objects

14.1

General CIP objects

116

Lenze · Decentralised frequency inverter 8400 protec (EtherNet/IP™ option) · Communication Manual · DMS 3.0 EN · 07/2014 · TD17

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

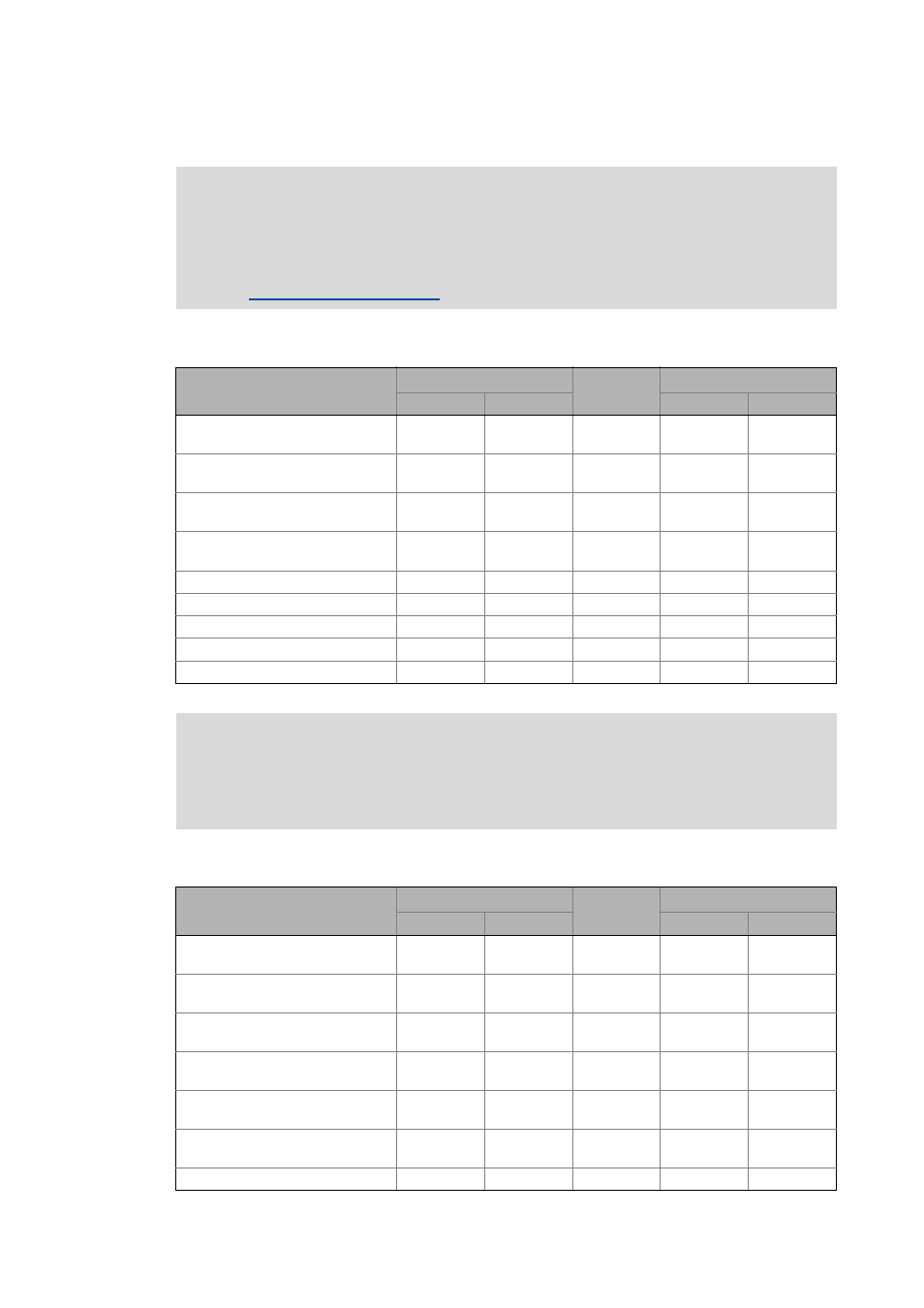

Data mapping of the output assemblies

Data mapping of the input assemblies

Note!

In order to be able to use the torque control for the assembly object instances 22 (0x16),

23 (0x17), 72 (0x48), 73 (0x49), the "DriveMode" attribute has to be written by means of

explicit message transfer.

Data component

[Bits 0 ... 7]

Class

Instance

Number

Attribute

Name

Number

Name

Number

RunFwd [Bit 0]

Control

Supervisor

0x29

1

Run1

3

RunRev [Bit 1]

Control

Supervisor

0x29

1

Run2

4

FaultReset [Bit 2]

Control

Supervisor

0x29

1

FaultRst

12

NetCtrl [Bit 5]

Control

Supervisor

0x29

1

NetCtrl

5

NetRef [Bit 6]

AC Drive

0x2A

1

NetRef

4

Drive Mode [Bits 0 ... 7]

AC Drive

0x2A

1

DriveMode

6

Speed Reference [Bits 0 ... 7]

AC Drive

0x2A

1

SpeedRef

8

Torque Reference [Bits 0 ... 7]

AC Drive

0x2A

1

TorqueRef

12

Custom Output [Bits 0 ... 7]

Note!

In case of the assembly object instances 21 (0x15) und 23 (0x17), NetCtrl (Bit 5) and

NetRef (Bit 6) must be set in order that the inverter can receive start/stop commands

and speed/torque commands via the network.

Data component

[Bits 0 ... 7]

Class

Instance

Number

Attribute

Name

Number

Name

Number

Faulted [Bit 0]

Control

Supervisor

0x29

1

Faulted

10

Warning [Bit 1]

Control

Supervisor

0x29

1

Warning

11

Running1 (Fwd) [Bit 2]

Control

Supervisor

0x29

1

Running1

7

Running2 (Rev) [Bit 3]

Control

Supervisor

0x29

1

Running2

8

Ready [Bit 4]

Control

Supervisor

0x29

1

Ready

9

CtrlFromNet [Bit 5]

Control

Supervisor

0x29

1

CtrlFromNet

15

RefFromNet [Bit 6]

AC Drive

0x2A

1

RefFromNet

29