8adapting the application individually – Lenze E84AVSCx 8400 StateLine C User Manual

Page 64

8

Adapting the application individually

8.3

Implementing more additional functions in the signal flow

64

Lenze · 8400 StateLine · Operating instructions · from Firmware V06.00 · DMS 1.2 EN · 12/2012 · TD05

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

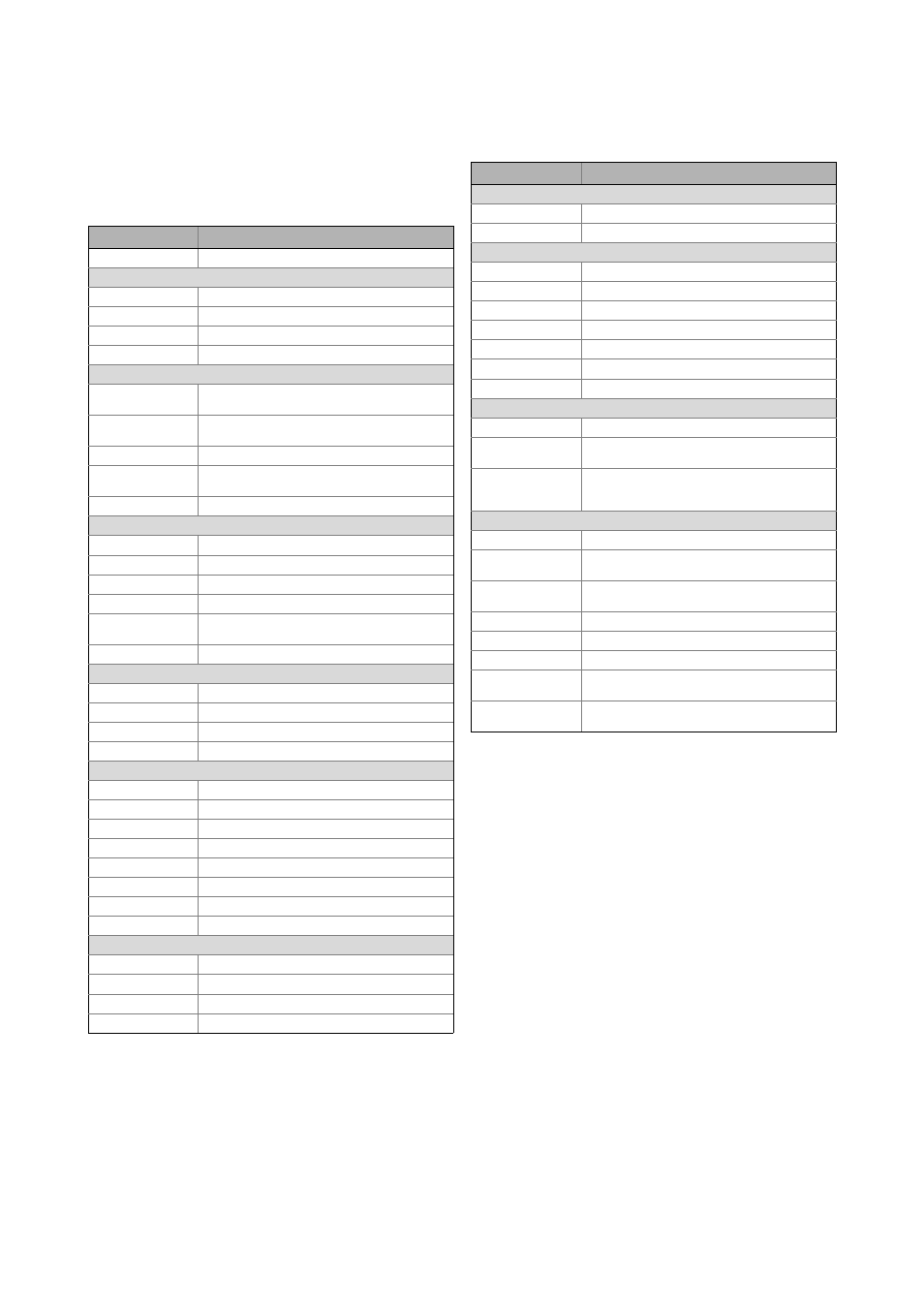

Brief description of the input and output interfaces

For a detailed interface description see the reference

manual.

Input interface

Function

nMainSetValue_a

Main speed setpoint

Motor potentiometer (L_MPot_1)

bMPotEnable

Activating the motor potentiometer function

bMPotInAct

Activating the inactive function

bMPotUp

Increasing the speed setpoint

bMPotDown

Decreasing the speed setpoint

Ramp function generator (L_NSet_1)

bRFG_Stop

Maintain the current value of the

main setpoint integrator

bRFG_0

Lead the main setpoint integrator

to "0" within the current Ti times

bJogSpeed1/2/4/8

Selection inputs for fixed changeover setpoints

bJogRamp1/2/4/8

Selection inputs for alternative

acceleration/deceleration times

nAuxSetValue_a

Additional speed setpoint

Process controller (L_PCTRL_1)

nPIDVpAdapt_a

Percentage adaptation of gain Vp

nPIDActValue_a

Speed or actual sensor value (actual process value)

nPIDInfluence_a

Limitation of the influencing factor in percent

nPIDSetValue_a

Sensor or process setpoint

bPIDEnable

InfluenceRamp

Activate ramp for influencing factor

bPIDOff

Switch off the I component of the process controller

Motor interface (LS_MotorInterface)

nTorqueMotLim_a

Torque limitation in motor mode

nTorqueGenLim_a

Torque limitation in generator mode

nVoltageAdd_a

Additive voltage impression

nBoost_a

Additional setpoint for the motor voltage at speed = 0

Motion Control Kernel

bSetDCBrake

Manual DC-injection braking (DCB)

bSetQuickstop

Enable quick stop (QSP)

bRLQCw

Activate clockwise rotation (fail-safe)

bRLQCcw

Activate counter-clockwise rotation (fail-safe)

bSetSpeedCcw

Change of direction of rotation

bMBRKRelease

Holding brake control: Release/apply brake

nPWMAngleOffset

Additional offset for the electrical angle of rotation

wSMControl

Interface to optional safety engineering

Device control (LS_DriveInterface)

wCANDriveControl

Control word via system bus (CAN)

wMCIDriveControl

Control word via communication module

bCInh

Enable/Inhibit controller

bFailReset

Reset error message

Output interface

Function

Ramp function generator (L_NSet_1)

bSpeedSetReached

Status signal "setpoint = 0"

bSpeedActEqSet

Status signal "actual speed value = speed setpoint"

Motor interface (LS_MotorInterface)

nMotorSpeedAct_a

Actual speed value

nMotorTorqueAct_a

Actual torque

bImaxActive

"Current setpoint inside the limitation" status signal

nMotorCurrent_a

Current stator current/effective motor current

nDCVoltage_a

Actual DC-bus voltage

nMotorVoltage_a

Current motor voltage/inverter output voltage

bQSPIsActive

Status signal "quick stop is active"

Motion Control Kernel

nMotorSpeedSet_a

Speed setpoint

bBrakeReleaseOut

Holding brake control: Trigger signal for the holding

brake control switching element via a digital output

bBrakeReleased

Holding brake control: Status signal of the brake control

with regard to the release and application times of the

brake

Device control (LS_DriveInterface)

wDriveControlStatus

Status word of the controller (based on DSP-402)

wStateDeterm

FailNoLow

Display of the status determining error

(Low word)

wStateDeterm

FailNoHigh

Display of the status determining error

(High word)

bDriveFail

Status signal "controller in error status"

bDriveReady

Status signal "controller is ready for operation"

bCInhActive

Status signal "controller inhibit is active"

bSpeedCcw

FALSE = Clockwise rotation (Cw)

TRUE = Counter-clockwise rotation (Ccw)

bSpeedActCompare

Status signal "speed setpoint or actual value <

comparison value (C00024)"