7diagnostics & troubleshooting – Lenze E84AVSCx 8400 StateLine C User Manual

Page 51

Lenze · 8400 StateLine · Operating instructions · from Firmware V06.00 · DMS 1.2 EN · 12/2012 · TD05

51

7

Diagnostics & troubleshooting

7.5

Error messages

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

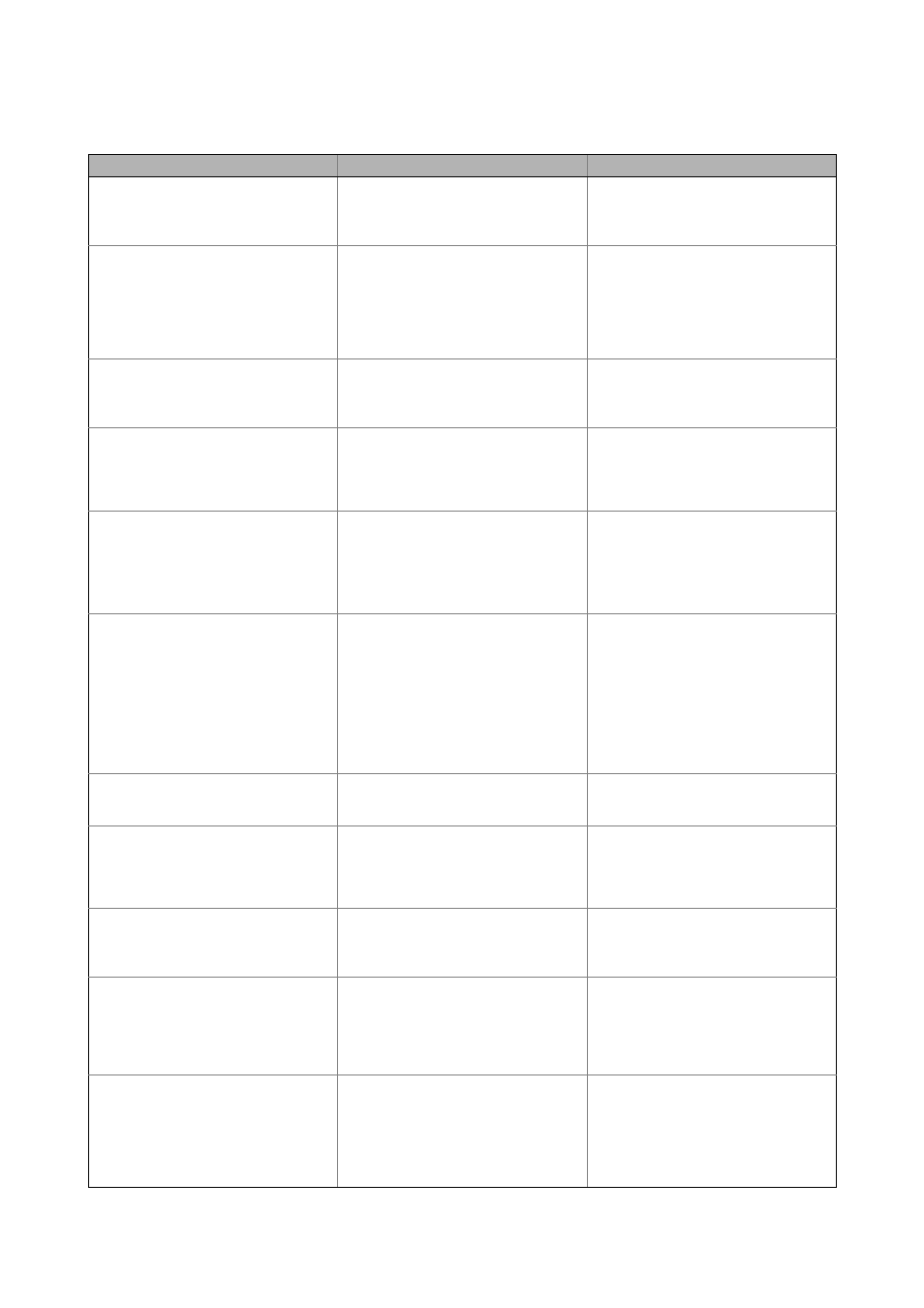

OC14: Direct-axis current controller

limitation

Direct-axis current controller limitation is

active.

• Observe load requirements.

• Correct dimensioning or reduce

setpoint generation dynamics if

necessary.

OC15: Cross current controller limitation

Cross current controller limitation is

active.

• Observe load requirements.

• Correct dimensioning or reduce

setpoint generation dynamics if

necessary.

• Check parameter setting of the current

controller with regard to the motor

controllers (e.g. reduce Vp).

OC16: Torque controller limitation

Actuator limitation according to speed

controller.

• Observe load requirements.

• Correct dimensioning or reduce

setpoint generation dynamics if

necessary.

OC17: Clamp sets pulse inhibit

Due to a short overcurrent, the inverter

was switched off for a short time (clamp

disconnection).

• Check and, if required, correct

dimensioning of the load with regard

to the installed device power.

• Reduce the dynamics of the setpoint

change or speed control.

OH1: Heatsink overtemperature

The heatsink temperature is higher than

the fixed limit temperature (90 ° C).

Maybe the ambient temperature of the

controller is too high or the fan or its

ventilation slots are dirty.

• Check control cabinet temperature.

• Clean filter.

• Clean controller.

• If required, clean or replace the fan.

• Provide for sufficient cooling of the

device.

OH3: Motor temperature (X106) triggered The motor temperature monitoring

function at the plug connector X106,

terminal T1 /T2, has tripped.

Possible causes:

• The motor is overheated so that the

thermal contact integrated into the

motor has been switched.

• An open circuit or a loose contact at the

connections mentioned above has

occurred.

• Check motor temperature monitoring.

• Provide for sufficient cooling of the

motor.

• Check terminals for open circuit or

loose contact.

OH4: Heatsink temp. > shutdown temp. -

5°C

The heatsink temperature now only

differs by 5 °C from the shutdown

temperature of the motor.

Prevent further heating, i.e. reduce motor

load or set controller inhibit so that the

heatsink can cool down again.

OS1: Max. speed limit reached

The device has recognised that the

maximum speed has been reached.

• Limit setpoint selection to maximum

values.

• Adjust set speed limitation (C00909)

and frequency limitation (C00910) if

necessary.

OT1: Max. torque reached

The device indicates that the maximally

possible torque at the motor shaft has

been reached.

• C00057 displays the current torque.

Reduce motor load.

OT2: Speed controller output limited

The output of the speed controller has

reached the internal limit value. In this

state, the speed controller is not able

anymore to correct the system deviation.

• Only with "Closed loop" operation or

vector control (SLVC).

• Observe load requirements.

• Correct dimensioning or reduce

setpoint generation dynamics if

necessary.

OU: DC bus overvoltage

The device has detected an overvoltage in

the DC bus. To protect the device

hardware, the inverter control is switched

off.

• If this error message remains active

longer than the time set in C00601, a

"Fault" is tripped.

• Reduce load in generator mode.

• Use a brake resistor.

• Use a regenerative power supply unit.

• Establish a DC-bus connection.

Error message

Cause

Remedies