Bolt / nut tightening torques – Landoll HSB 71-1 through 131-1 SOIL BUILDER Coulter Chisel - Extended Frame User Manual

Page 14

1K705

Page 12

Fasteners

Before operating your Brillion Zone Commander,

check all hardware for tightness. Use the

Tightening Torque Chart reproduced below as

a guide.

After a few hours use, check entire machine

and tighten any loose nuts or bolts. Daily or

periodic checks should be made thereafter.

M

aintenance

M

aintenance

791rev6-23-08

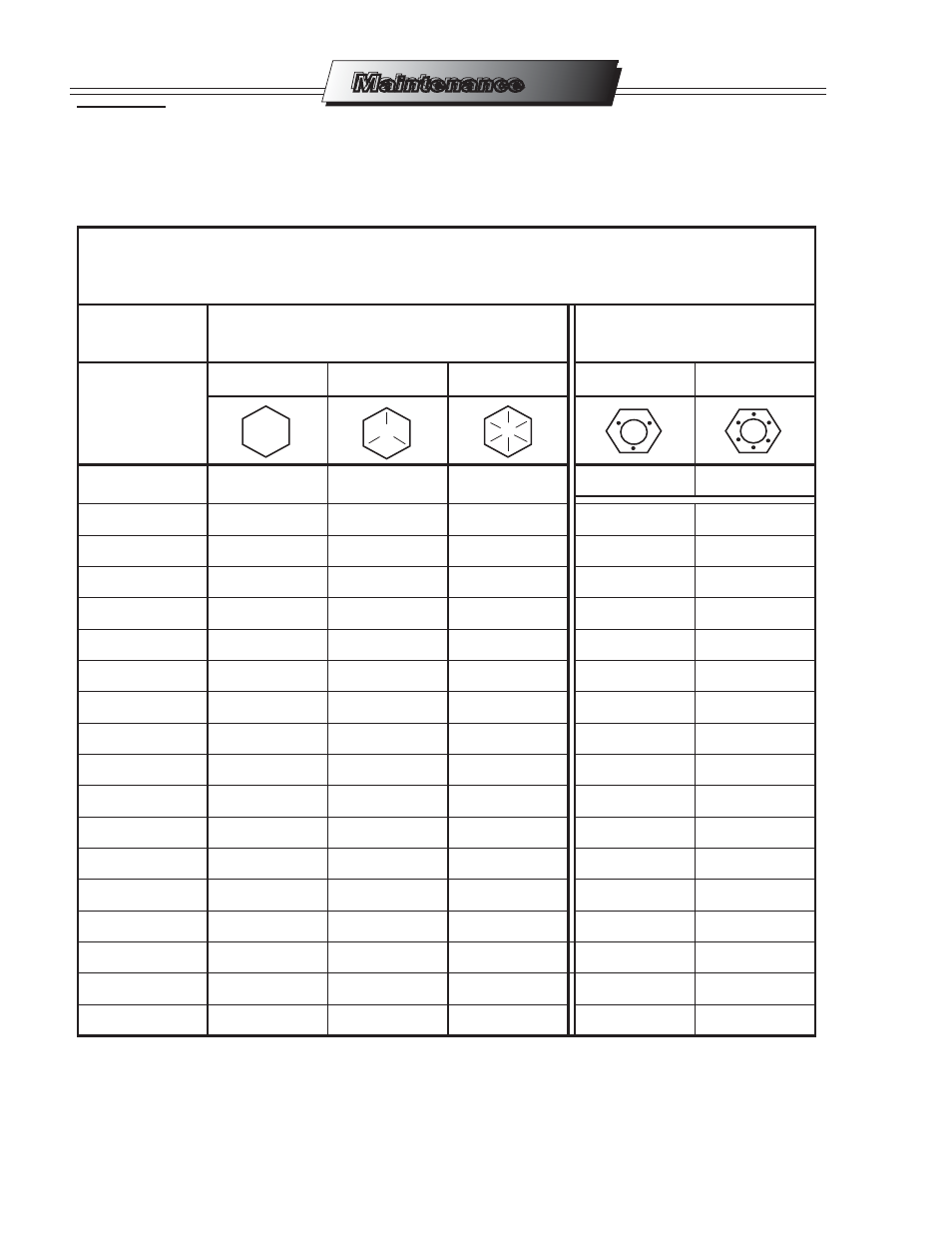

BOLT / NUT TIGHTENING TORQUES

For Fine Threads Multiply Chart Values by 1.1

THREAD

BOLT GRADE

PLATED, STOVER

SIZE

LOCK NUTS

GRADE 2

GRADE 5

GRADE 8

GRADE B

GRADE C

MIN / MAX

MIN / MAX

1/4-20

5

8

12

5 / 7

7 / 10

5/16-18

11

17

24

10 / 12

11 / 16

3/8-16

20

30

45

15 / 20

20 / 28

7/16-14

30

50

70

23 / 32

31 / 43

1/2-13

50

75

105

37 / 50

45 / 62

9/16-12

70

110

155

50 / 70

70 / 95

5/8-11

100

150

210

70 / 95

90 / 122

3/4-10

170

270

375

125 / 165

155 / 210

7/8-9

165

430

610

185 / 250

225 / 312

1-8

250

645

910

275 / 375

360 / 462

1 1/8 - 7

355

795

1290

1 1/4 - 7

500

1120

1820

1 3/8 - 6

745

1670

2710

1 1/2 - 6

870

1950

3160

•VALUES ARE GIVEN IN FOOT-POUNDS.

•USE GRADE B LOCK NUTS WITH GRADE 2 AND GRADE 5 BOLTS ONLY.

•USE GRADE C LOCK NUTS WITH GRADE 8 BOLTS ONLY.