Landoll 4K647 FLAIR SHREDDER V-BELT User Manual

Landoll Special machinery

4K647

V-BELT INSTALLATION FOR FLAIR SHREDDER

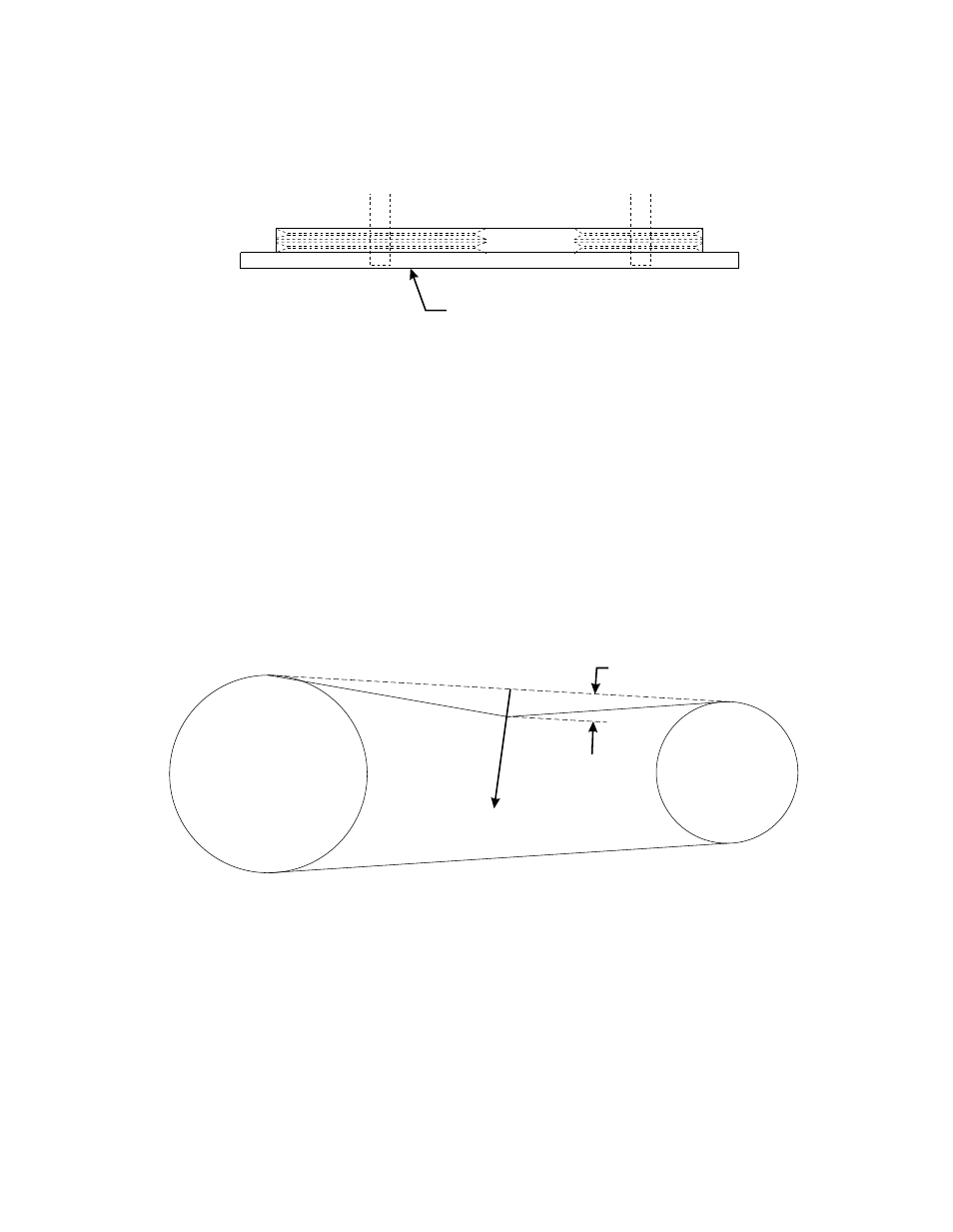

TO CHECK PULLEY ALIGNMENT

Straight Edge

Lay straight edge against both pulleys. Straight edge should touch on

both edges of each pulley. It may be necessary to slide the pulley in

or out of the shaft, as well as move the gearbox to properly align the

belts.

It is important to maintain pulley alignment for normal belt life.

TO CHECK PROPER BELT TENSION ON MODELS

WITH MULTIPLE “C” SECTION BELTS

1-1/4

Force

1. Using spring scale at right angles to the center of the span, apply a force

to one belt large enough to deflect the belt 1-1/4”.

2. The force required should be about 20 lbs. For a new belt that is being

tightened for the first time the force required for 1-1/4” deflection should be

30 lbs.

3. At the end of 2 - 4 hours of operation the should be retightened to the

normal tension.

4. After 24 - 48 hours the belt tension should be rechecked. Either too high

or too low a belt tension will shorten belt life.