Landoll 171824 SHIM KIT User Manual

Gap between bearing and roller axle shaft shoulder, Notice

F-655 Edition

Brillion Farm Equipment

1-1

rev6-12-12

Brillion, Wisconsin 54110

INSTALLATION INSTRUCTIONS

SHIM PROCEDURE

SHIM KIT P/N 171824

WFPD22-36, WFPO22-36,

WFPC22-36 & WFPDS22-36

(WING FLOAT PULVERIZERS)

1.

Install the left bearing assembly to the Center Frame

to hold the Center Roller Axle Assembly as per

assembly instructions shown on the Wing Float

Pulverizer Operator’s Manual (2P542).

2.

Begin installation of the right hand bearing assembly

similarly.

— As you are lining up the center roller axle up to

the right bore, you should notice if there may be

a gap, either between the flangettes and the

center frame or between the bearing and the

shoulder on the roller axle shaft.

NOTICE

Gap Between Flangettes and

Center Frame Hanger Bracket

When the Center Roller Axle Assembly is installed to the

point that the flangette halves are clamped around the

bearing, and there is a gap between the flangettes and

the center frame hanger bracket (as shown in

Figure 1-3), additional shims must be added.

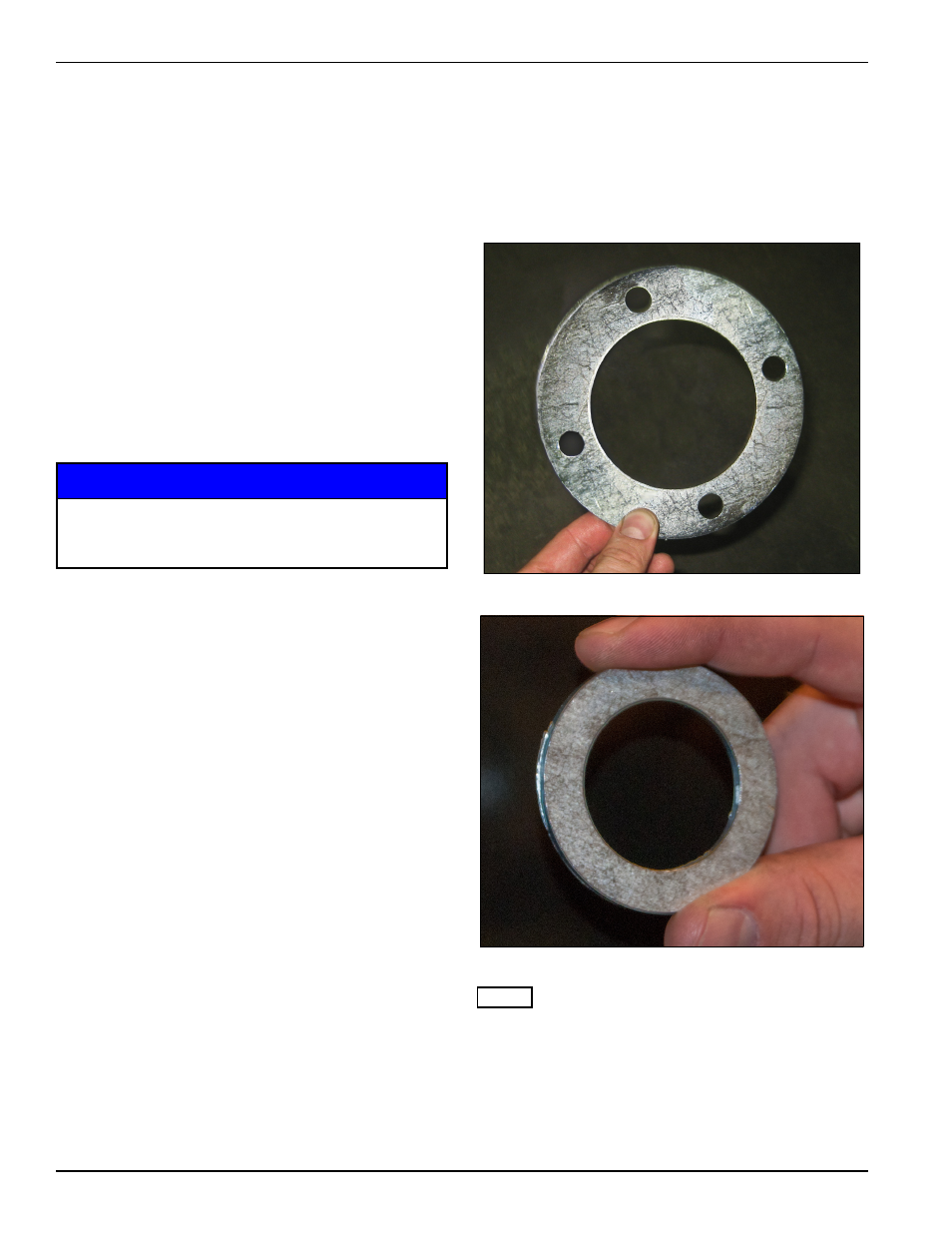

The shim for this type of gap, shown in Figure 1-1, should

be installed between the flangettes and the Center Frame

bracket. See Figure 1-5. In the instance that more than

one shim is needed, put an equal number of shims on

either side of the Center Frame to obtain a proper fit.

Gap Between Bearing and Roller

Axle Shaft Shoulder

When the Center Roller Axle Assembly is installed to the

point that the flagette halves are clamped around the

bearing, and there is a gap between the bearing and the

shoulder on the Roller Axle Shaft (as shown in

Figure 1-4), additional shims must be added.

The shim for this type of gap, shown in Figure 1-2, should

be installed between the bearing and the shoulder on the

Roller Axle Shaft. See Figure 1-5. In the instance that

more than one shim is needed, put an equal number of

shims on either side of the Center Frame to obtain a

proper fit.

Figure 1-1: Outside Shim

Figure 1-2: Inside Shim

NOTE

After installing the appropriate shims, proceed with

normal installation instructions, including use of

proper fasteners and torque specifications.

The bearings must be shimmed correctly to avoid

premature failure of the part. Correct installation

is vital to the longevity of the equipment.