Appendix – INFICON SQC-310 Thin Film Deposition Controller User Manual

Page 88

Appendix

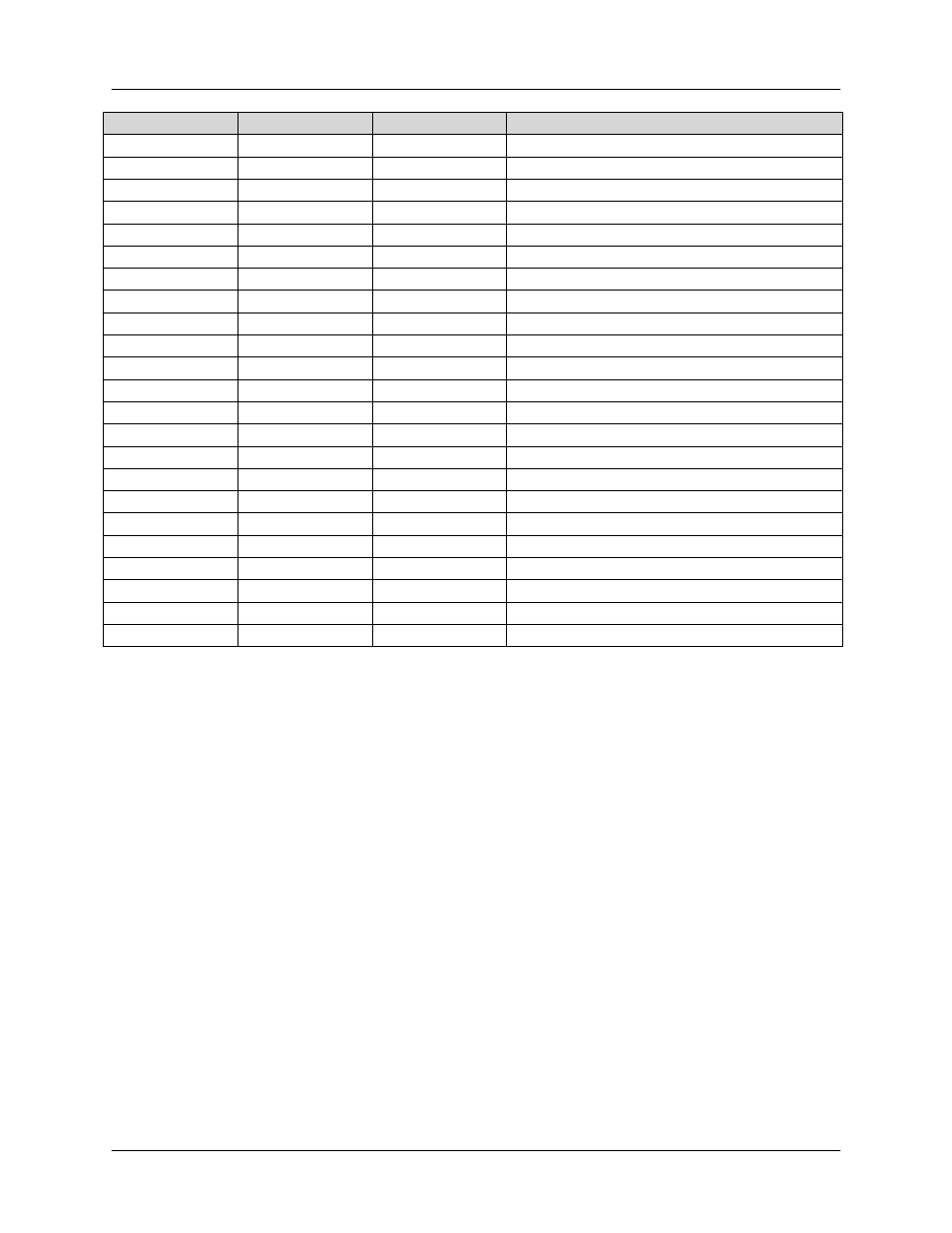

Formula

Density

Z-Ratio

Material Name

VO

2

4.340

*1.000

Vanadium Dioxide

W

19.300

0.163

Tungsten

WB

2

10.770

*1.000

Tungsten Boride

WC

15.600

0.151

Tungsten Carbide

WO

3

7.160

*1.000

Tungsten Trioxide

WS

2

7.500

*1.000

Tungsten Disulphide

WSi

2

9.400

*1.000

Tungsten Suicide

Y

4.340

0.835

Yttrium

Y

2

O

3

5.010

*1.000

Yttrium Oxide

Yb

6.980

1.130

Ytterbium

Yb

2

O

3

9.170

*1.000

Ytterbium Oxide

Zn

7.040

0.514

Zinc

Zn

3

Sb

2

6.300

*1.000

Zinc Antimonide

ZnF

2

4.950

*1.000

Zinc Fluoride

ZnO

5.610

0.556

Zinc Oxide

ZnS

4.090

0.775

Zinc Sulfide

ZnSe

5.260

0.722

Zinc Selenide

ZnTe

6.340

0.770

Zinc Telluride

Zr

6.490

0.600

Zirconium

ZrB

2

6.080

*1.000

Zirconium Boride

ZrC

6.730

0.264

Zirconium Carbide

ZrN

7.090

*1.000

Zirconium Nitride

ZrO

2

5.600

*1.000

Zirconium Oxide

Z-Factor is used to match the acoustic properties of the material being deposited to the

acoustic properties of the base quartz material of the sensor crystal.

Z-Factor = Z

q

/ Z

m

For example, the acoustic impedance of gold is Z=23.18, so:

Gold Z-Factor = 8.83 / 23.18 = .381

Unfortunately, Z Factor is not readily available for many materials. Z Factor can be

calculated empirically using this method:

1. Deposit the material until Crystal Life is near 50%, or near the end of life,

whichever is sooner.

2. Place a new substrate adjacent to the used quartz sensor.

3. Set QCM Density to the calibrated value; Tooling to 100%. Zero thickness.

4. Deposit approximately 1000 to 5000 Å of material on the substrate.

5. Use a profilometer or iterferometer to measure the actual substrate film thickness.

6. Adjust the Z Factor of the instrument until the correct thickness reading is shown.

Another alternative is to change crystals frequently. For a crystal with 90% life, the error

is negligible for even large errors in the programmed versus actual Z Factor.