Enerpac PL200-Series User Manual

Page 5

5

5.0 ASSEMBLY AND SETUP

5.1 Important Receiving Instructions

Visually inspect all components for shipping damage. Shipping

damage is not covered by warranty. If shipping damage is found,

notify carrier at once. The carrier is responsible for all repair and

replacement costs resulting from damage in shipment.

NOTICE

The jack rear access cover must be removed to gain

access to various components and service items discussed in

sections 5.2 through 5.4. Refer to Section 7.1 for cover removal

instructions.

5.2 Hydraulic Oil Level

Before using the jack or connecting the air supply, remove the

oil fi ll plug from the hydraulic reservoir and check the oil level.

Add additional hydraulic oil to reservoir if oil level is low. See

Section 7.3 for oil level diagram, oil specifi cations and additional

instructions.

5.3 Compressed Air Requirements

The compressed air system used with the jack must be capable

of providing 80 - 100 psi [5,5 - 6,9 bar] @ 130 CFM [3681 l/min].

The jack is equipped with an air fi lter/regulator assembly, which

consists of an air regulator, pressure gauge and moisture trap.

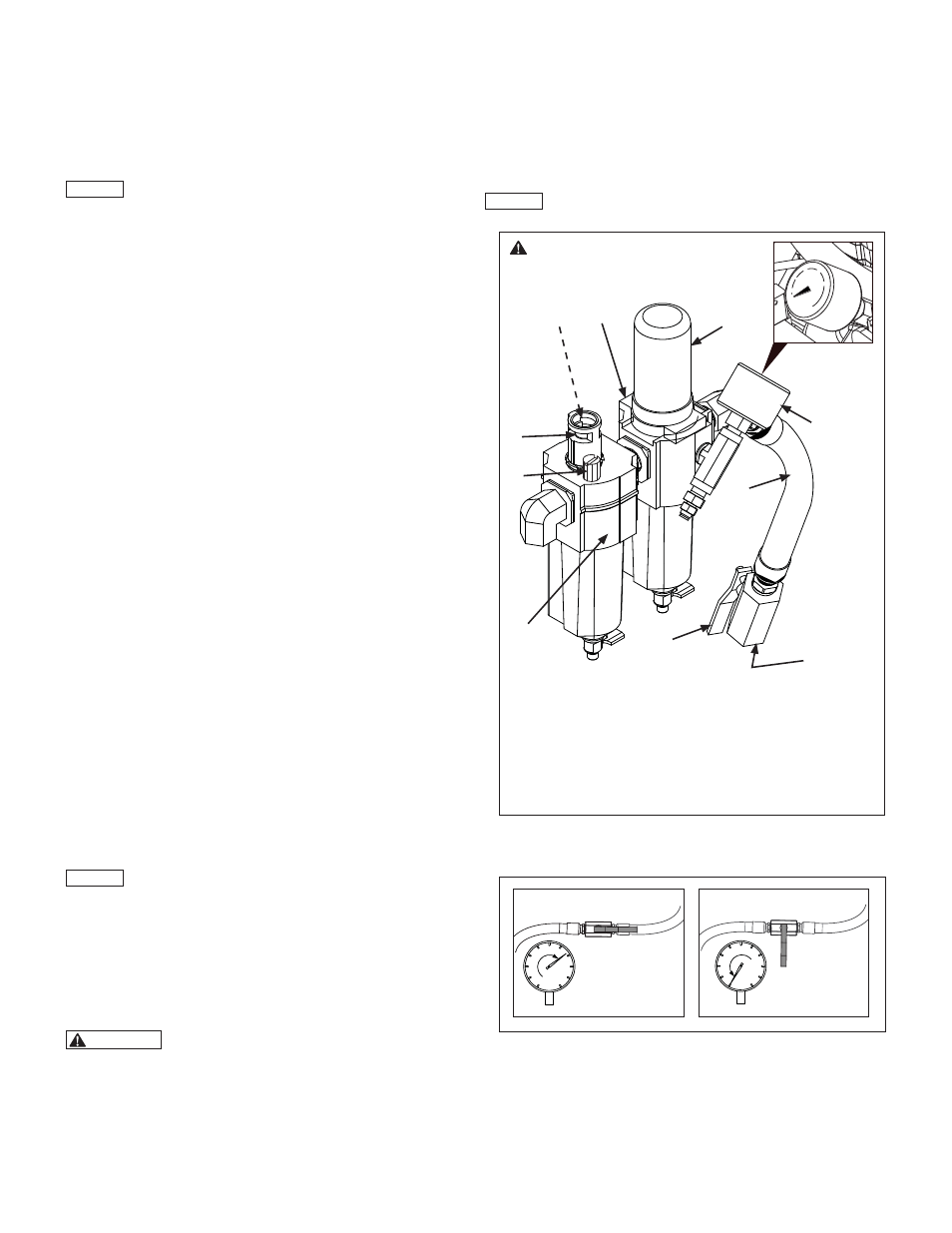

See Figure 3, items A, B and F.

A short hose connects the fi lter/regulator to the air-shutoff valve.

The air inlet connection is a 1/2 inch NPT female thread. See

Figure 3, items C, D and E. Refer to Figure 4 for shut-off valve

positions.

For effi

ciency of output and reliable operation, an air supply

line of not less than 0.82 inch [20,8 mm] internal diameter is

recommended. (Nominal Pipe Size - 3/4 inch pipe).

Check the air pressure gauge with the pendant UP button

depressed and the jack air motor running. Be sure there is NO

load on the cylinder. This will provide an accurate dynamic air

pressure reading.

The minimum dynamic air pressure required to operate the jack

will vary, but is typically about 50 to 60 psi [3,4 - 4,1 bar].

Approximately 90 to 100 psi [6,2 to 6,9 bar] dynamic air pressure

will be needed for the jack to achieve its rated 200 ton [1779 kN]

lifting capacity.

Lifting speed and torque can be adjusted using the knob located

at the top of the fi lter/regulator. To prevent damage to jack

pneumatic components, the regulator air pressure setting should

not exceed 120 psi [8,3 bar].

NOTICE

Pressure settings of above 120 psi [8,3 bar] will result

in reduced air motor life and will void the Enerpac product

warranty.

5.4 Air Lubrication

The jack pneumatic system is equipped with an automatic air

line lubricator. See Figure 3, items G, H, I and J. Lubricated air

is necessary to provide lubrication for the air motor and to help

prevent rust formation.

WARNING

Be certain that regulator air pressure gauge

indicates zero (0) psi/bar before removing lubricator fi ll plug.

Lubricant may spray from fi ll opening if fi ll plug is removed

while system is pressurized, even when air hose has been

disconnected and air shut-off valve is in the closed position.

Serious eye injury and/or skin penetration could result. If any

pressure is indicated, relieve pressure as described in

Section 7.2 of this manual.

Before using the jack, check the lubricant level in the sight gauge

on the air line lubricator. Add additional lubricant if low. Refer to

Section 7.6 for air lubricant recommendations and additional air

lubricator information.

After the air supply hose has been connected, observe the oil

fl ow through the oil drip window while the cylinder is in motion.

Verify that the lubricator drip speed is set at 4 to 5 drops per

minute.

NOTICE

Air motor must be running and cylinder must be

moving up or down when checking lubricator oil drip speed.

Be sure air pressure gauge (item B)

indicates zero (0) psi/bar before

removing lubricator fi ll plug (item H).

Figure 3, Filter/Regulator, Air Line Lubricator

and Air Shut-off Valve

A

B

C

D

F

J

G

E

H

I

Key:

A. Air Regulator Knob

B. Air Pressure Gauge

C. Air Inlet Hose

D. Air Inlet Connection

(1/2 inch NPT)

E. Air-shutoff Valve

F. Air Filter/Regulator

(with moisture trap)

G. Air Line Lubricator

H. Lubricator Fill Plug

I. Oil Drip Window

J. Oil Drip Speed Control

(inside oil drip housing)

5

Figure 4, Air Shut-Off Valve Positions

OPEN

CLOSED

0