Enerpac PL200-Series User Manual

Page 13

13

4. Remove fi lter bowl and inspect the air fi lter element (inside

fi lter bowl). Replace fi lter element if dirty.

NOTICE

Filter/regulator is manufactured by Norgren. Contact

Norgren for detailed maintenance instructions, fi lter elements

and replacement parts.

7.6 Air Line Lubricator (See Figure 13)

Every 30 hours of operation:

1. Remove the jack rear access cover. Refer to Section 7.1.

2. Check the sight gauge on the air line lubricant bowl. The

lubricant level should be at least 1/2 full.

NOTICE

If lubricant level is low, add additional lubricant as

described in steps 3 through 6. If lubricant level is OK, skip these

steps and go to step 7.

3. Completely relieve any trapped pressure in the jack hydraulic

and pneumatic systems. Disconnect the air supply hose

from the air shut-off valve. Follow procedure in Section 7.2.

WARNING

Be certain that jack pneumatic system is

completely depressurized and regulator air pressure gauge

indicates zero (0) psi/bar before removing lubricator fi ll plug.

Lubricant may spray from fi ll opening if fi ll plug is removed

while system is pressurized, even when air hose has been

disconnected and air shut-off valve is in the closed position.

Serious eye injury and/or skin penetration could result.

4. Remove

the

lubricator

fi ll plug. Add additional lubricant as

required, until the level reaches the top of the lubricant bowl

sight gauge. DO NOT OVERFILL!

For ambient temperatures above 32°F [0°C], use a high quality

SAE 10 [ISO 32] air tool lubricant. For ambient temperatures

below 32°F [0°C], use only a glycol-based anti-freeze air tool

lubricant (Enerpac part number DD5142835 or equivalent).

NOTICE

Lubricant level must not be higher then top of site

gauge. Do not operate jack with excess lubricant in lubricant

bowl. If lubricant bowl is overfi lled, jack air logic circuit may

become fl ooded with lubricant, preventing normal operation

of jack.

5. Reinstall the lubricator fi ll plug.

6. Reconnect the air supply hose. Be sure the air shut-off valve

is in the OPEN position.

7. Check the lubricator drip speed in the drip window:

• Drip speed should be 4 to 5 drops per minute. Always check

the drip speed while the cylinder is advancing or retracting.

• If drip speed is too slow or too fast, readjust the drip speed

as required. Use a fl at blade screwdriver to turn the drip

speed adjustment screw.

NOTICE

Air line lubricator is manufactured by Norgren. Contact

Norgren for detailed maintenance instructions, fi lter elements

and replacement parts.

8. Reinstall the jack rear access cover. Refer to Section 7.1.

7.7 Air Muffl

er (See Figure 14)

Every 30 hours of operation:

1. Remove the jack rear access cover. Refer to Section 7.1.

2. Disconnect the air supply hose from the air shut-off valve.

Completely relieve any trapped air in the jack pneumatic

system. Follow procedure in Section 7.2.

3. Inspect the air muffl

er. Remove any loose dirt or debris.

4. If old air muffl

er is very dirty or clogged, replace it with a new

air muffl

er. Use only a 25 micron air muffl

er of the original

specifi cations (Enerpac Part No. DD4791116 or equivalent).

Air Muffl

er

Figure 14, Air Muffler

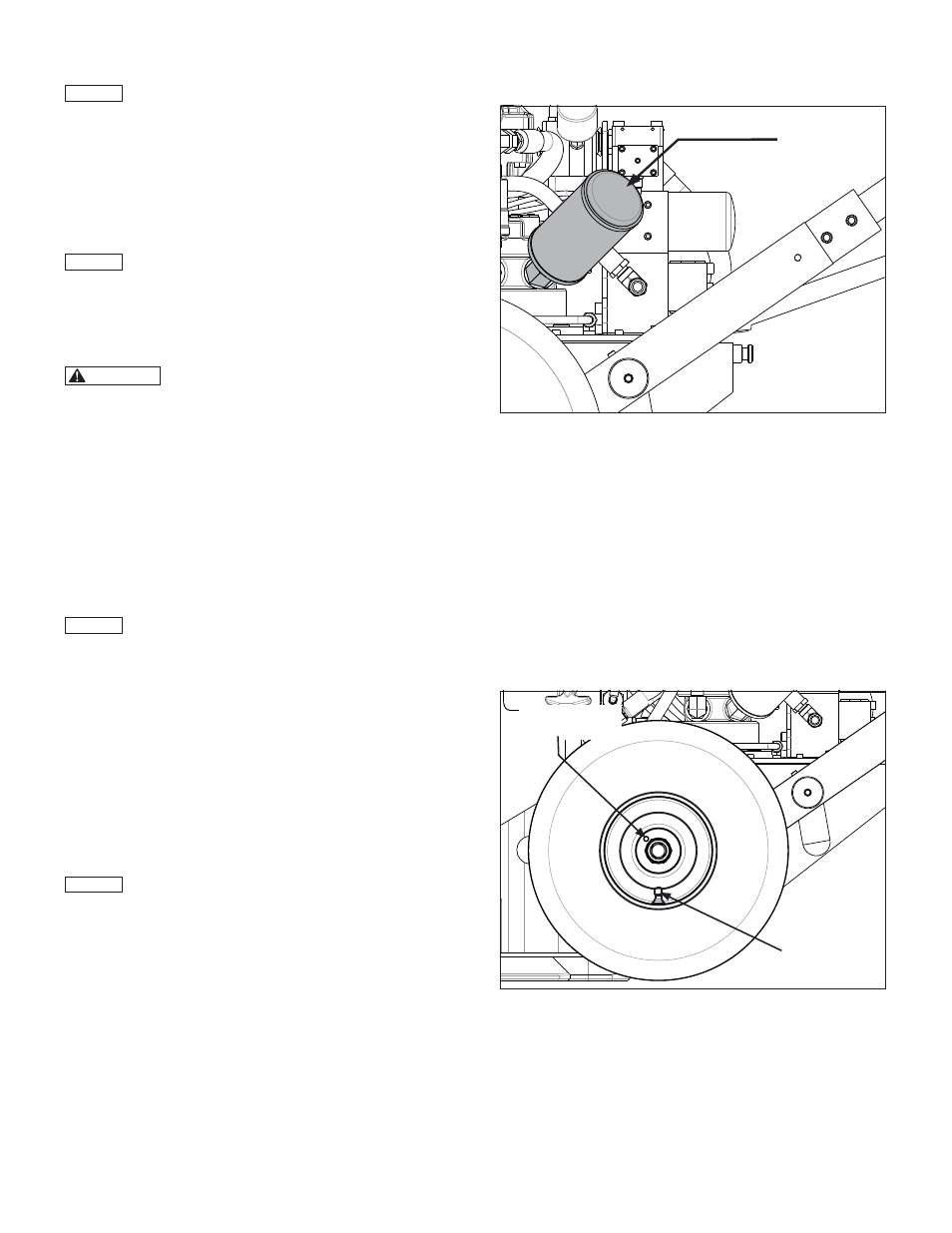

7.8 Wheels and Tires (See Figure 15)

Every 30 hours of operation:

• Check the tires for wear or damage. Replace as required.

• Check the tire infl ation pressure. Each tire should be infl ated

to 90 psi [6,2 bar].

Every 12 months:

• Each wheel hub contains a grease fi tting. Lubricate both wheel

bearings with a high quality wheel bearing grease.

• Inspect the caster wheel for damage and check that it turns

and pivots freely. Remove any loose dirt and lubricate bearings

with oil. Refer to Figure 7 in Section 5.7 of this manual.

Wheel Bearing

Grease Fitting

Tire Air Valve

Figure 15, Wheels and Tires