Enerpac PL200-Series User Manual

Page 15

15

7. Remove any loose dirt or debris from the cylinder threads

and inspect the threads for obvious wear or damage. If the

old lubricant has dried-up, clean the threads with a brush

and some solvent before applying new lubricant.

8. Using an oil bottle with spout, apply two vertical streams

of SAE 80w-90 gear oil [ISO 150] on the exposed cylinder

threads, from top to bottom of cylinder. See Figure 19.

Apply two

streams of

gear oil to threads.

(see Section 7.9 for

detailed instructions)

Figure 19, Cylinder Thread Lubrication

9. Remove the lifting sling and lower the jack front access

cover to its normal position, so it is supported by the chain

drive plate. The front access cover and protective bellows

should now completely cover the cylinder threads and chain

drive mechanism.

WARNING

Be certain that jack front access cover is

installed and fully lowered before starting the jack. Never

operate the jack with the front access cover removed or

raised, either during lubrication and maintenance procedures

or when the jack is in use. Failure to observe this precaution

may result in persons becoming entangled in the moving

parts of the chain drive mechanism. Serious personal injury

could result.

10. Reconnect the air supply hose and move the air-shutoff

valve to the OPEN position.

WARNING

In the following step, it will be necessary to

extend and retract the cylinder several times. Stay clear of

the cylinder and related components. Keep hands and

fi ngers away from pinch and crush points. Serious personal

injury could occur if these precautions are not observed.

Refer to Section 1.3 of this manual for additional hazard

information.

11. With no load on the jack, fully extend and retract the cylinder

several times to distribute the gear oil on the cylinder

threads, and on the chain and drive components. Verify

proper operation.

12. Reinstall the jack rear access cover. Refer to Section 7.1.

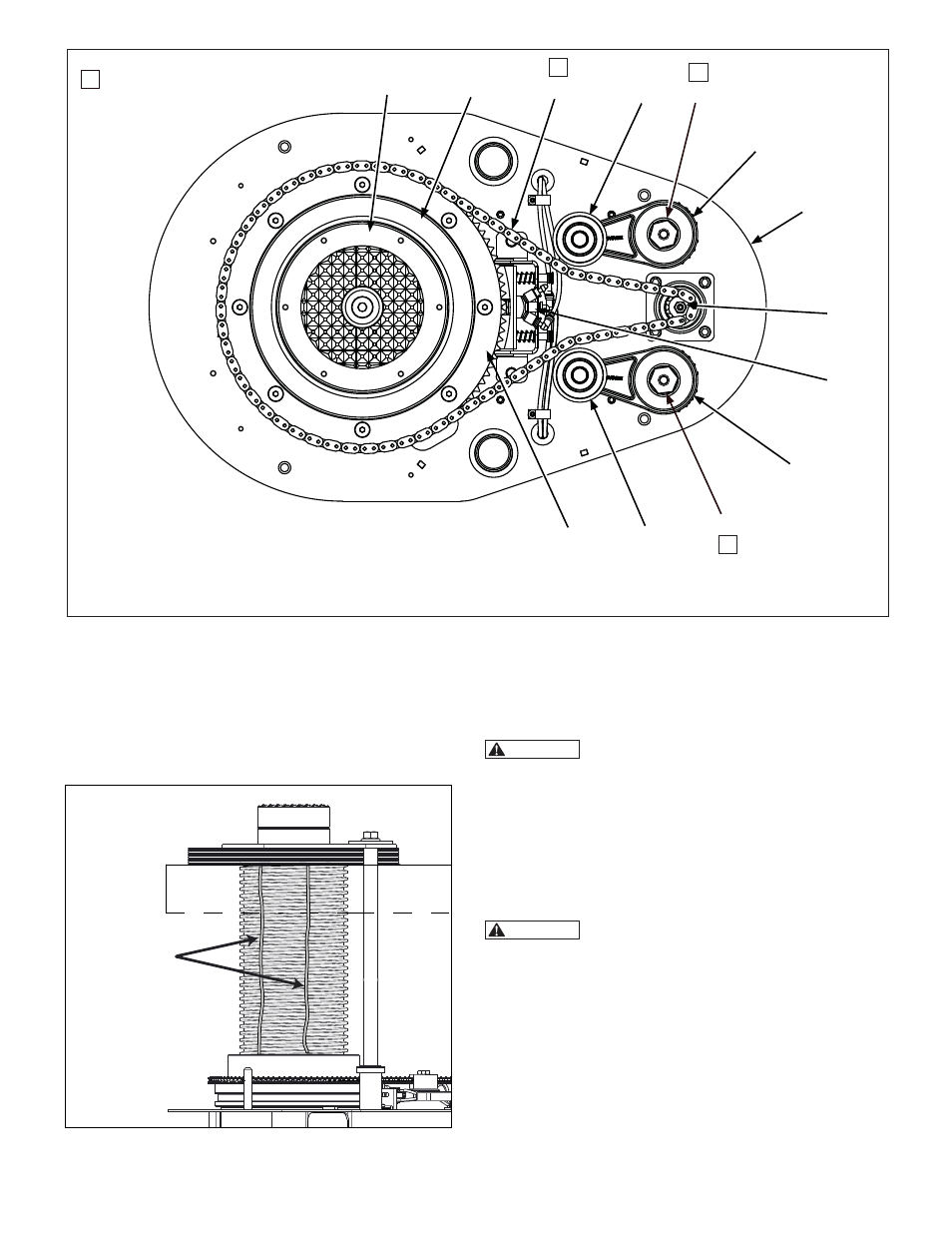

Figure 18, Lock Nut Chain Drive Assembly

C

D

E1

G

E1

D

I

Key:

A. Hydraulic Cylinder

B. Lock Nut

C. Drive Chain

D. Roller

E 1. Chain Tensioner

E 2. Tensioner Pivot Shaft

F. Chain Drive Plate

G. Drive Sprocket

H. Proximity Sensors

I. Lock Nut Sprocket

A

H

B

F

E2

E2

✽

✽

✽

✽

Lubricate with gear oil.

(see Section 7.9 for

detailed instructions)