Warning – Enerpac PL200-Series User Manual

Page 16

16

16

8.0 TROUBLESHOOTING

The information in the Troubleshooting Guide (refer to Table 10) is

intended as an aid to help diagnose and correct various possible

problems that may occur.

For repair service, contact your local Enerpac Authorized Service

Center. Only an Enerpac Authorized Service Center should

service the jack and its components.

WARNING

Failure to observe and comply with the following precautions

could result in death or serious personal injury. Property

damage could also occur.

• Never tighten or loosen hydraulic fi ttings while jack hydraulic

system is pressurized. Escaping oil under pressure can

penetrate the skin, causing serious personal injury.

• Keep hands, fi ngers and other body parts clear of pinch

points and moving parts when observing operation during

troubleshooting.

• To prevent injury, always be sure the jack air shut-off valve

is in the CLOSED position and that the air supply hose is

disconnected before beginning any maintenance, adjustment

or repair procedures. Be certain that any trapped pressure is

completely relieved as described in Section 7.2 of this manual.

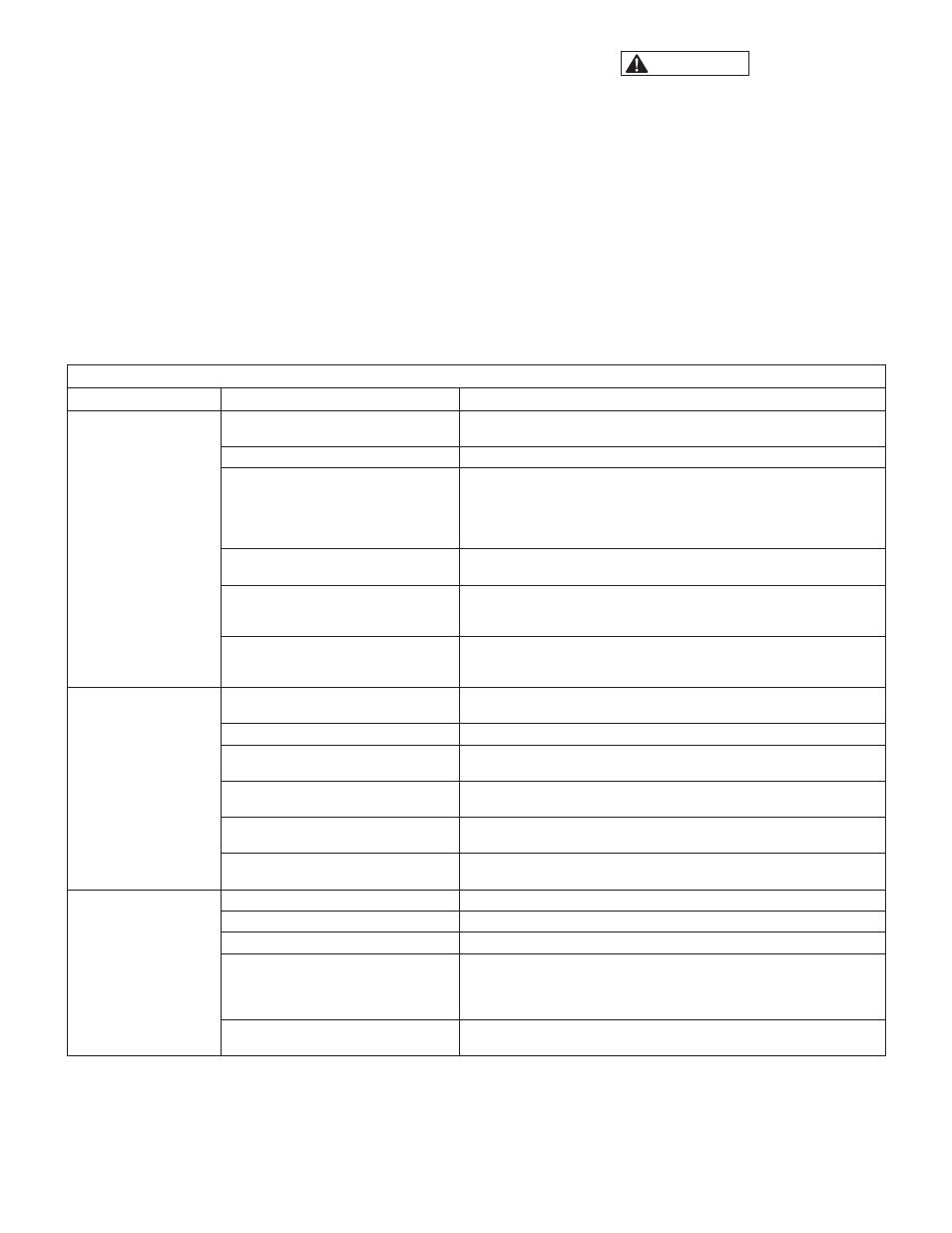

Table 10 - Troubleshooting Guide

Symptom

Possible Cause

Solution

1. Sporadic cylinder

action and/or sluggish

operation.

a. Air trapped in hydraulic system.

Cycle cylinder up and down several times to bleed trapped air.

b. Low oil level in hydraulic reservoir.

Add Enerpac HF oil as required.

c. Insuffi

cient compressed air pressure

or volume.

Check air pressure at fi lter/regulator. Increase regulator setting if pressure

shown on gauge is too low.

If necessary, increase volume of compressed air or increase size of supply

air line to meet airfl ow and pressure requirements.

d. Clogged or blocked pump intake

screen.

Have hydraulic reservoir and intake screen fl ushed and cleaned by

Enerpac Authorized Service Center.

e. Pneumatic control circuit components

leaking, worn, damaged or out of

adjustment.

Have pneumatic control circuit inspected by Enerpac Authorized Service

Center. Repair or replace components as required.

f. Seal wear, internal leakage, worn

components and/or other internal

damage.

Have hydraulic system inspected by Enerpac Authorized Service Center.

Repair or replace components as required.

2. Noisy operation.

a. Air trapped in hydraulic system.

Cycle cylinder up and down several times to bleed trapped air.

b. Low oil level in hydraulic reservoir.

Add Enerpac HF oil as required.

c. Air muffl

er missing or damaged.

Replace air muffl

er.

d. Air leaks in hydraulic system.

Check all points where air might leak into system. Tighten, repair or replace

components as required.

e. Clogged or blocked pump intake

screen.

Have hydraulic reservoir and intake screen fl ushed and cleaned by

Enerpac Authorized Service Center.

f. Air motor worn or damaged.

Have air motor inspected by Enerpac Authorized Service Center. Repair or

replace components as required.

3. Oil is overheating.

a. Low oil level in hydraulic reservoir.

Add Enerpac HF oil as required.

b. Oil viscosity too high or too low.

Drain oil from reservoir and refi ll with Enerpac HF oil.

c. Excessive cycling of cylinder.

Reduce cycling of cylinder. Allow time for oil to cool between lifts.

d. Jack is overloaded.

Reduce load or use a diff erent jack of higher capacity.

NOTICE: Oil may overheat if jack is overloaded, and oil runs over the relief

valve for a prolonged period of time.

e. High pressure leakage at the pump.

Have hydraulic system inspected by Enerpac Authorized Service Center.

Repair or replace components as required.

(Continued on next page)