Enerpac PL200-Series User Manual

Page 10

10

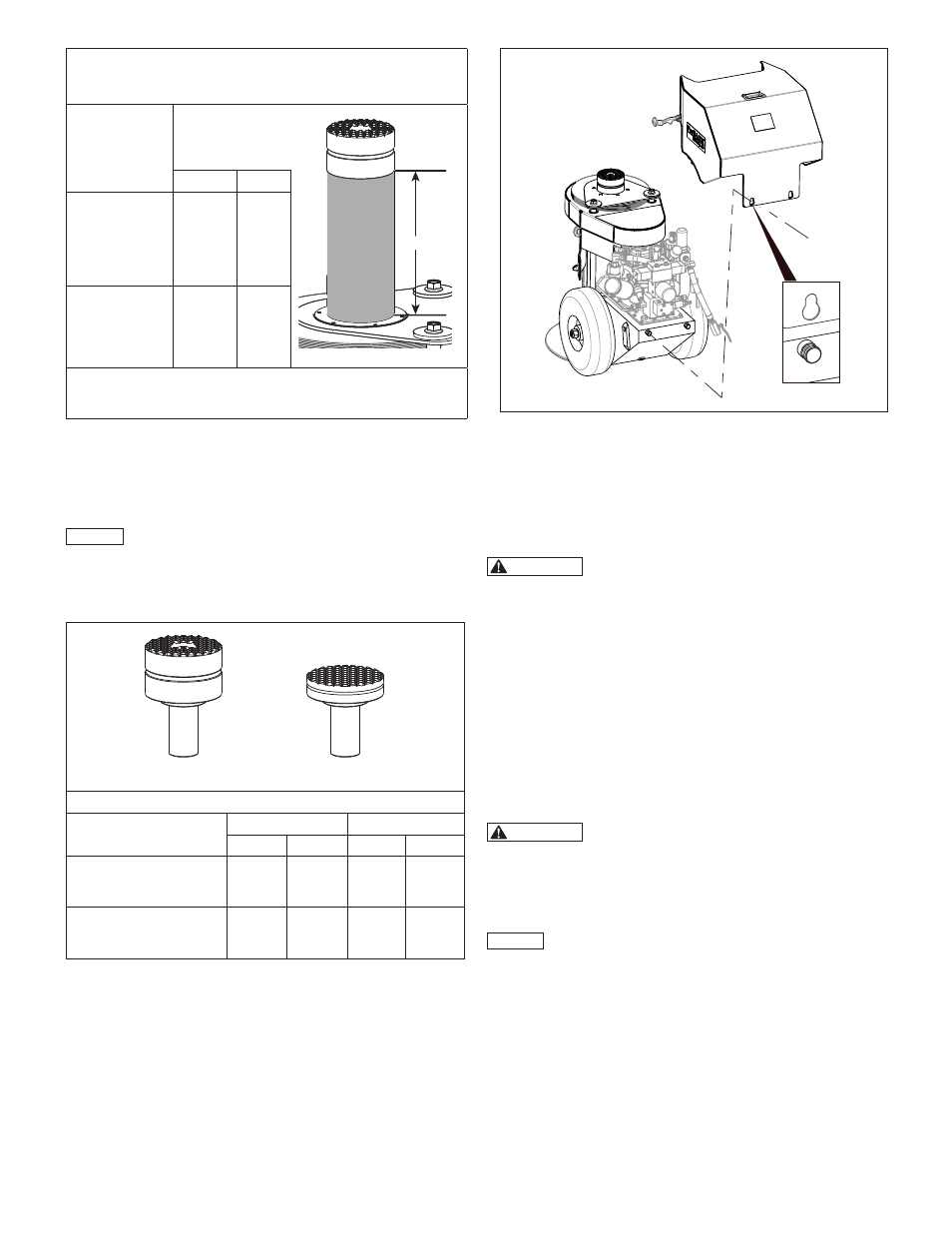

Table 6 - Maximum Additional Stack Height

(Using optional PLB and PLE Series

extensions and PLS Series spacers)

Jack

Model

Maximum

Additional

Stack Height

(dimension “X”)

X

inches

mm

PL20014-ASA

28.0

711

PL20025-ASA

9.0

229

Stack height (dimension “X”) includes total combined height of all

installed extensions and spacers. Load cap height is NOT included in

the stack height.

6.7 Load Caps

A swivel load cap is included with the jack as standard equipment.

A non-swivel load cap is available as an optional accessory, and

is for use in applications where a reduced collapsed height is

needed. Refer to Table 7 for load cap model numbers.

NOTICE

Use a swivel load cap to properly engage angled lifting

points. A swivel load cap should always be used when the

amount of misalignment between a non-swivel load cap and the

lifting point is too large to be compensated for by use of plywood

or other suitable high-friction compression material alone.

DD4880045SR

PLC1

Table 7 - Load Caps

Load Cap Model

Height (each)

Weight (each)

inches

mm

pounds

kg

DD4880045SR

Swivel Load Cap

(standard)

3.3

84

20.2

9,2

PLC1

Non-swivel Load Cap

(optional accessory)

0.88 22

10.4

4,7

NOTICE: Dimensions and weights shown are approximate.

7.0 MAINTENANCE

7.1 Rear Access Cover Removal

The jack rear access cover must be removed to gain access to

various inspection, lubrication and maintenance points. Remove

the jack rear access cover as described in the following steps:

1. Unhook the rubber latches on each side of the cover.

2. Pull up on the cover until the round openings on the cover

keyways align with the cover support pins on the rear of the

hydraulic reservoir.

Figure 10, Rear Access Cover Removal

3. Gently guide the cover rearward until it has cleared the pins

and then lift the cover off of the jack.

4. Reverse steps 1, 2 and 3 to reinstall the cover. At the keyway

openings, be sure the groove in each cover support pin is

aligned with the cover sheet metal before fully installing the

cover onto the jack.

WARNING

Always reinstall the jack rear access cover

before using the jack. Except as necessary for maintenance

procedures, do not operate jack with cover removed. Serious

personal injury could occur if persons make contact with hot

surfaces or pressurized lines and components while cover is

removed. Damage could also occur if falling objects drop

onto exposed components.

7.2 Depressurizing the Jack Hydraulic and Pneumatic

Systems

For some maintenance procedures contained in Section 7 of

this manual, it is required that the jack hydraulic and pneumatic

systems be depressurized before the procedure can begin. These

operations are necessary to ensure the safety of the maintenance

personnel.

WARNING

Failure to follow the procedure in the following

steps may result in unexpected start-up of jack while

maintenance and repair procedures are being performed.

Uncontrolled release of pressure may also occur if

pressurized components are opened or pressurized fi ttings

are loosened. Serious personal injury could result.

NOTICE

The hydraulic system must be depressurized fi rst,

before the pneumatic system is depressurized. Always be sure to

depressurize both systems.

1. Depressurize the jack hydraulic system, as described in

steps 1a through 1c:

a. Check that the jack is connected to the air supply and the

air-shutoff valve is in the OPEN position.

b. Be sure the cylinder is in the fully retracted position.

c. Depress the pendant UP button while watching the

cylinder. Release the UP button IMMEDIATELY when the

cylinder starts advancing (usually after about 1 or 2 seconds).

This procedure will relieve any trapped pressure in the jack

hydraulic system.