107. tapered bushing removal -52 – JLG 1500SJ Service Manual User Manual

Page 404

SECTION 5 - HYDRAULICS

5-52

– JLG Lift –

3121262

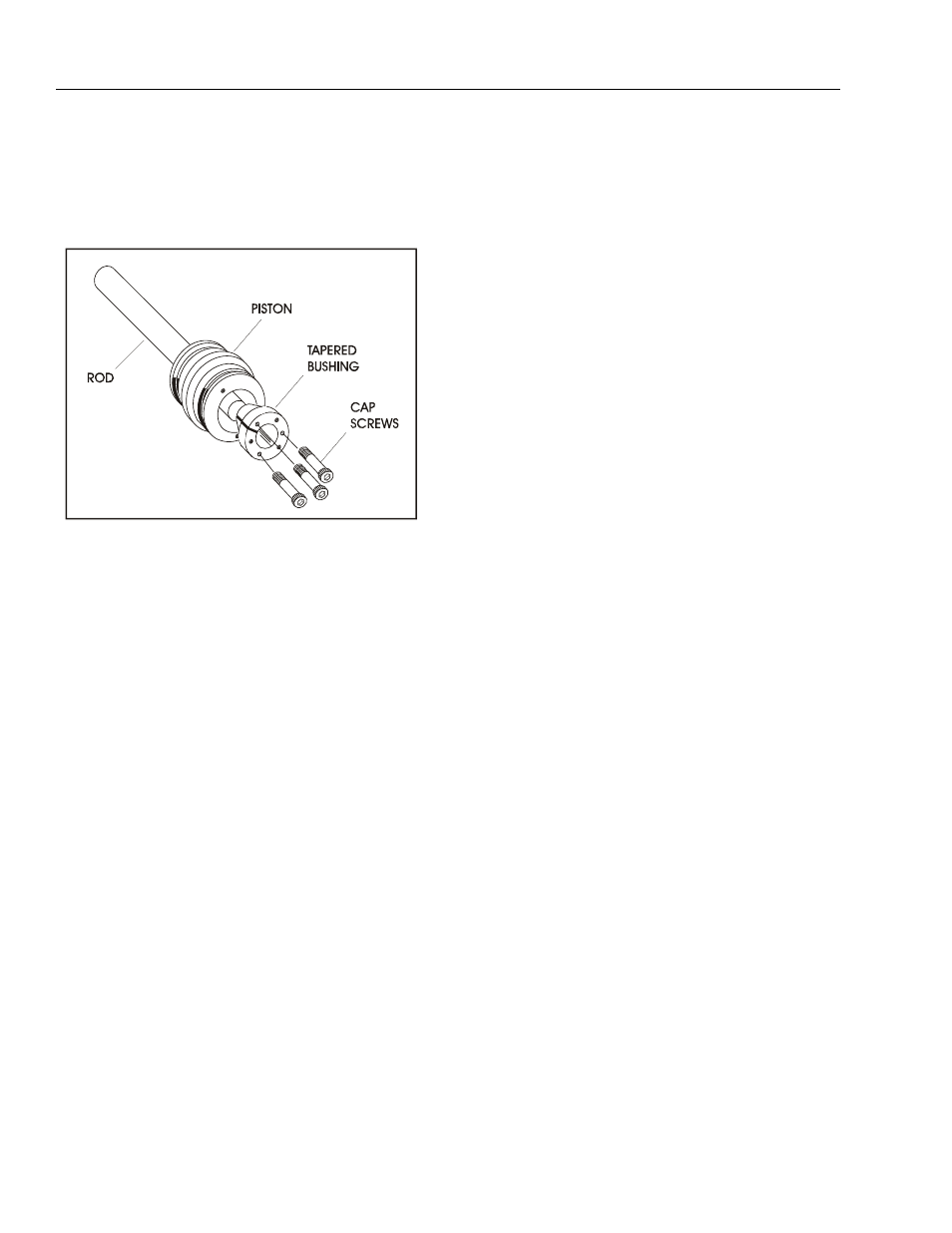

8. Using suitable protection, clamp the cylinder rod in

a vise or holding fixture as close to the piston as

possible.

9. Loosen and remove the capscrews which attach the

tapered bushing to the piston.

10. Insert the capscrews in the threaded holes in the

outer piece of the tapered bushing. Progressively

tighten the capscrews until the bushing is loose.

11. Remove the tapered bushing from the piston.

12. By hand, screw the piston counterclockwise and

remove it from cylinder rod.

13. Remove and discard the piston o-rings, seal rings,

and backup rings.

14. Remove the rod from the holding fixture. Remove

the cylinder head gland and washer ring. Discard all

seals on the cylinder head.

CLEANING AND INSPECTION

1. Clean all parts thoroughly in an approved cleaning

solvent.

2. Inspect the cylinder rod for scoring, tapering, ovality,

or other damage. If necessary, dress rod with

Scotch Brite or equivalent. Replace rod if necessary.

3. Inspect threaded portion of rod for excessive dam-

age. Dress threads as necessary.

4. Inspect inner surface of cylinder barrel tube for scor-

ing or other damage. Check inside diameter for

tapering or ovality. Replace if necessary.

5. Inspect threaded portion of barrel for damage. Dress

threads as necessary.

6. Inspect piston surface for damage and scoring and

for distortion. Dress piston surface or replace piston

as necessary.

7. Inspect threaded portion of piston for damage.

Dress threads as necessary.

8. Inspect seal and o-ring grooves in piston for burrs

and sharp edges. Dress applicable surfaces as nec-

essary.

9. Inspect cylinder head inside diameter for scoring or

other damage and for ovality and tapering. Replace

as necessary.

10. Inspect threaded portion of head for damage. Dress

threads as necessary.

11. Inspect seal and o-ring grooves in head for burrs

and sharp edges. Dress applicable surfaces as nec-

essary.

Figure 5-107. Tapered Bushing Removal