7 boom lubrication application, 8 platform leveling cylinder, Removal – JLG 1500SJ Service Manual User Manual

Page 305: Boom lubrication application -59, Platform leveling cylinder -59, Removal -59, 8 platform leveling cylinder removal

SECTION 4 - BOOM & PLATFORM

3121262

– JLG Lift –

4-59

4.7 BOOM LUBRICATION APPLICATION

This procedure applies to booms after assembly or during

annual application using Super Lube® lubricant (JLG p/n

3020042).

1. Position the boom on the boom rest using the 500lb

capacity setting.

2. Telescope main boom section as far as it will extend

at this position, approximately 3 ft. (0.9 m).

3. From the front of the machine (boom pivot end),

moderately apply lubricant to the interior surfaces of

the base boom, inner mid boom, and outer mid

boom. To prevent misdiagnosis of hydraulic leaks,

take care to prevent excessive application of lubrica-

tion.

4. At the rear of the machine, apply lubricant to the

side, top and bottom surfaces of the fly boom, outer

mid, and inner mid specifically to wear pad contact

paths. To prevent misdiagnosis of hydraulic leaks,

take care to prevent excessive application of lubrica-

tion.

5. After application of the lubricant is complete, cycle

the boom through its full range of travel 2 times.

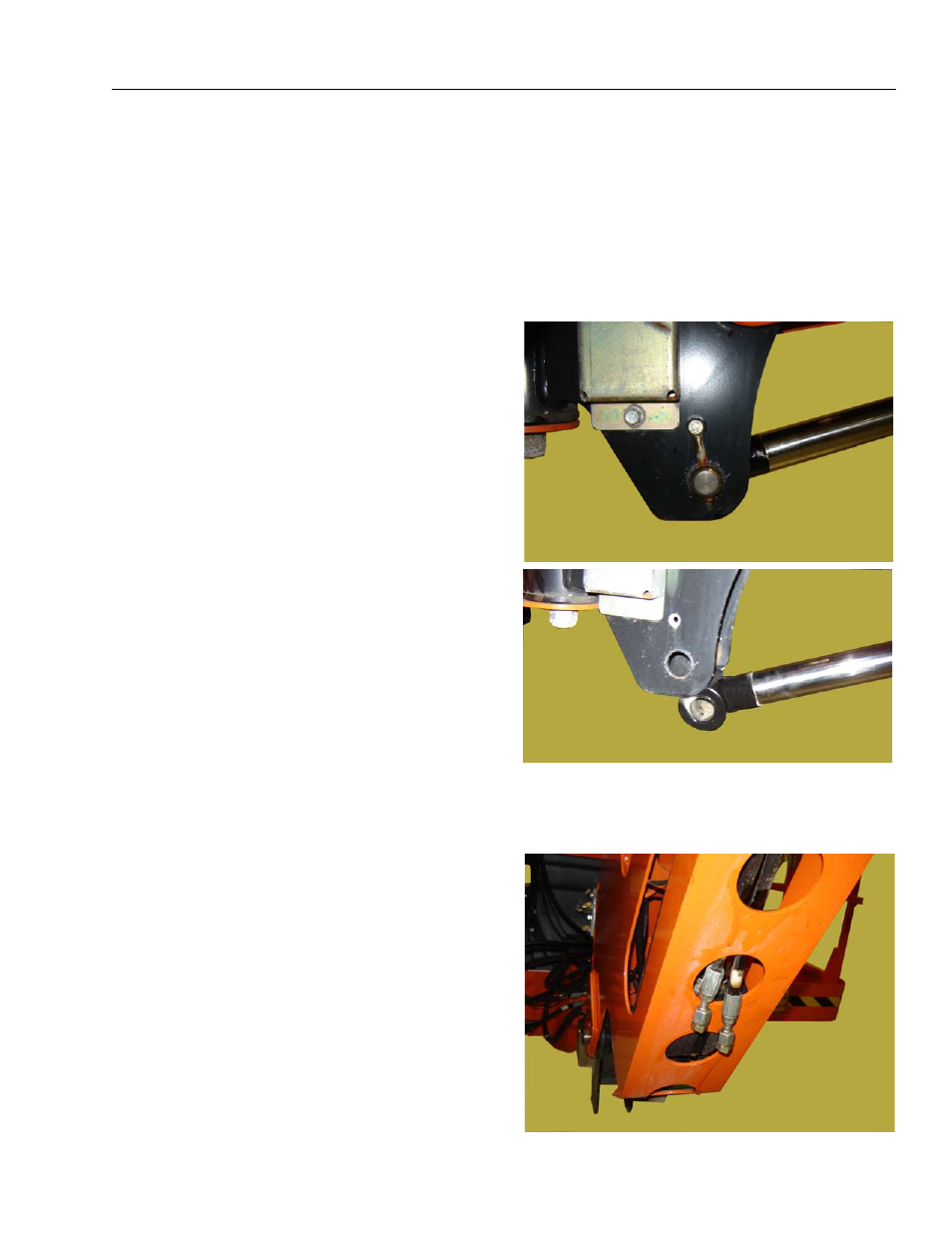

4.8 PLATFORM LEVELING CYLINDER

Removal

1. Ensure the platform is supported by blocking or an

adequate lifting device.

2. Remove the bolt and keeper pin securing the retain-

ing pin that secures the cylinder rod to the platform

assembly and remove the pin.

3. Tag and disconnect the hydraulic hoses from the

platform level cylinder. Cap or plug all openings. Tag

and disconnect the electrical harness running to the

cylinder.