Composite bearing installation -44, Rod seal installation -44 – JLG 1500SJ Service Manual User Manual

Page 396

SECTION 5 - HYDRAULICS

5-44

– JLG Lift –

3121262

8. Using suitable protection, clamp the cylinder rod in

a vise or holding fixture as close to the piston as

possible.

9. Loosen and remove the lock nut that secures the

piston to the cylinder rod.

10. Remove the piston from the cylinder rod.

11. Remove and discard the piston o-rings, seal rings,

and t-seal.

12. Remove the rod from the holding fixture. Remove

the cylinder head. Discard all seals on the cylinder

head.

CLEANING AND INSPECTION

1. Clean all parts thoroughly in an approved cleaning

solvent.

2. Inspect the cylinder rod for scoring, tapering, ovality,

or other damage. If necessary, dress rod with

Scotch Brite or equivalent. Replace rod if necessary.

3. Inspect threaded portion of rod for excessive dam-

age. Dress threads as necessary.

4. Inspect inner surface of cylinder barrel tube for scor-

ing or other damage. Check inside diameter for

tapering or ovality. Replace if necessary.

5. Inspect threaded portion of barrel for damage. Dress

threads as necessary.

6. Inspect piston surface for damage and scoring and

for distortion. Dress piston surface or replace piston

as necessary.

7. Inspect threaded portion of piston for damage.

Dress threads as necessary.

8. Inspect seal and o-ring grooves in piston for burrs

and sharp edges. Dress applicable surfaces as nec-

essary.

9. Inspect cylinder head inside diameter for scoring or

other damage and for ovality and tapering. Replace

as necessary.

10. Inspect threaded portion of head for damage. Dress

threads as necessary.

11. Inspect seal and o-ring grooves in head for burrs

and sharp edges. Dress applicable surfaces as nec-

essary.

12. Inspect cylinder head outside diameter for scoring

or other damage and ovality and tapering. Replace

as necessary.

13. If applicable, inspect rod and barrel bearings for

signs of correct excessive wear or damage. Replace

as necessary.

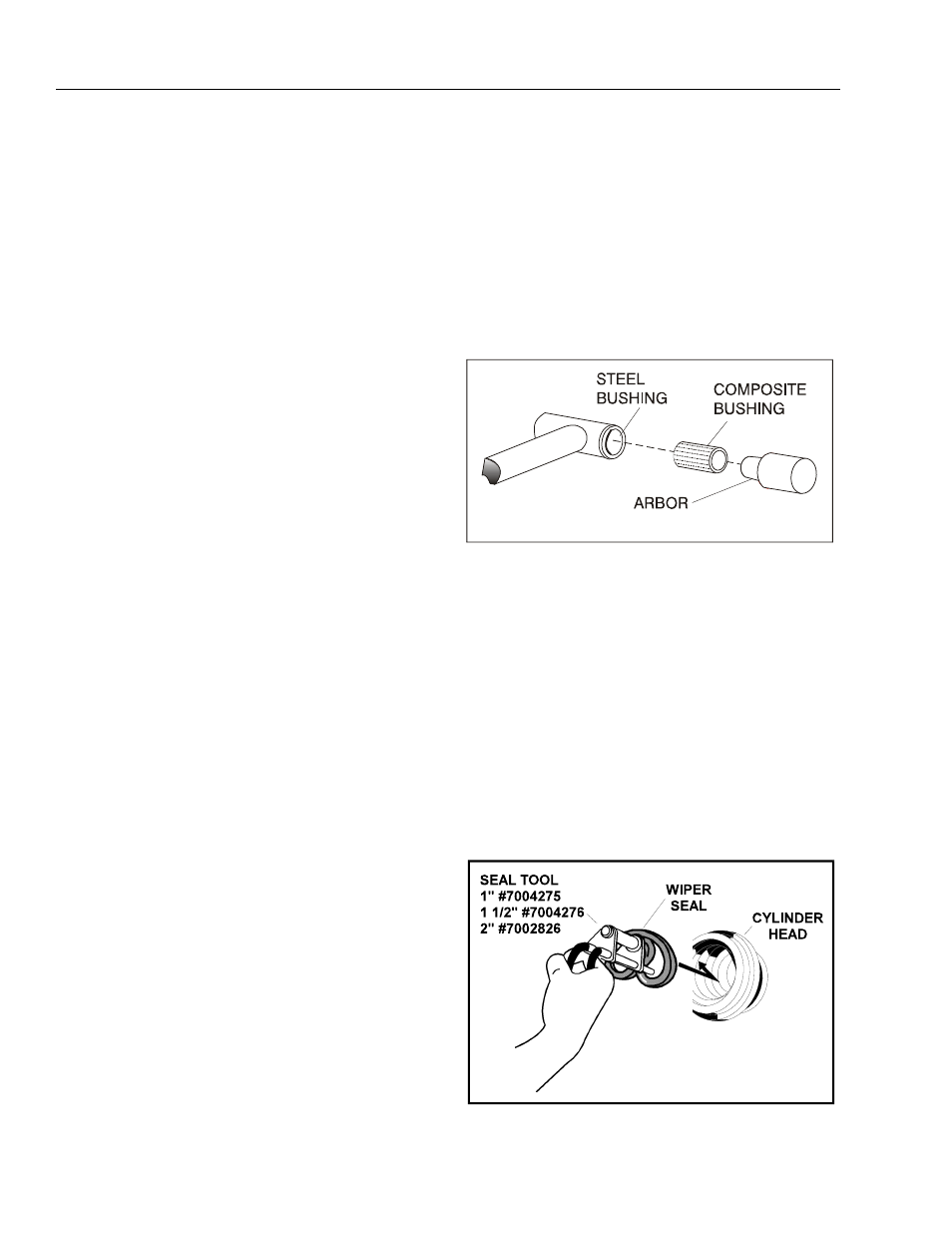

a. Thoroughly clean hole, (steel bushing) of burrs,

dirt etc. to facilitate bearing installation.

b. Inspect steel bushing for wear or other damage.

If steel bushing is worn or damaged, rod/barrel

must be replaced.

c. Lubricate inside of the steel bushing with WD40

prior to bearing installation.

d. Using an arbor of the correct size, carefully

press the bearing into steel bushing.

NOTE: Install pin into the composite bearing dry. Lubrication

is not required with nickel plated pins and bearings.

14. Inspect the oil ports for blockage or the presence of

dirt or other foreign material. Repair as necessary.

15. If applicable, inspect piston rings for cracks or other

damage. Replace as necessary.

ASSEMBLY

NOTE: Prior to cylinder assembly, ensure that the proper

cylinder seal kit is used. See your JLG Parts Manual.

Apply a light film of hydraulic oil to all components

prior to assembly.

1. A special tool is used to install a new rod seal into

the applicable cylinder head gland groove.

Figure 5-96. Composite Bearing Installation

Figure 5-97. Rod Seal Installation