Bell & Gossett 10-001-275 XLS Integrated Pump Controller User Manual

Page 21

21

Combo Up (After XL Start):

This setting controls the speed the VFD running

the main pump will be forced to when a fixed

speed lag pump starts. This helps prevent

overpressuring by reducing the capacity of the

VFD Pump, which is then being provided by the

fixed speed pump after it starts. Generally set to

1/3 the value between min speed and 32767.

This speed will be held for “Hold Sec”, which is

generally set to 1 (may need to increase for

systems using soft-starters for fixed speed lag

pumps).

Combo Down (After XL Stop):

This setting controls the speed the VFD running

the main pump will be forced to when a fixed

speed lag pump stops. This helps replace the

capacity provided by the fixed speed pump and

eliminate pressure dips when these pumps are

shut off. Generally set to 2/3 the value between

min speed and 32767. This speed will be held

for “Hold Sec”, which is generally set to 1.

Speed at 0 psi Startup:

This setting controls the speed the VFD of the

Jockey OR main will start if pressure is very low

when the pump starts (see deadband below).

This setting should be adjusted to be the point the

pump just begins to flow water at 0 psi discharge.

The actual starting speed will be calculated

between this speed and “Combo Down (After XL

Stop)” speed setting, depending on the actual

pressure at the time of start. A function is used to

calculate the speed between these points.

Threshold Deadband (psi):

This setting determines the pressure below

setpoint for determining starting speed. If set

to “20”, the threshold function is used to

calculate starting speed when pressure is

equal to or less than 20 psi below setpoint.

The VFD 1start factor corresponds to the starting

speed of the first main or Jockey pump starting on

VFD. A high value causes the VFD to start running at

a higher speed, creating more pressure. This helps

the system to reach the setpoint faster, but at the

same time the system may overshoot the setpoint

very quickly since the PID does not have enough

time to react to the fast occurring changes. A very

low value will make the system take a lot of time to

reach the setpoint.

Tap [Next] to move to the next Field Setup screen

Supplemental Control

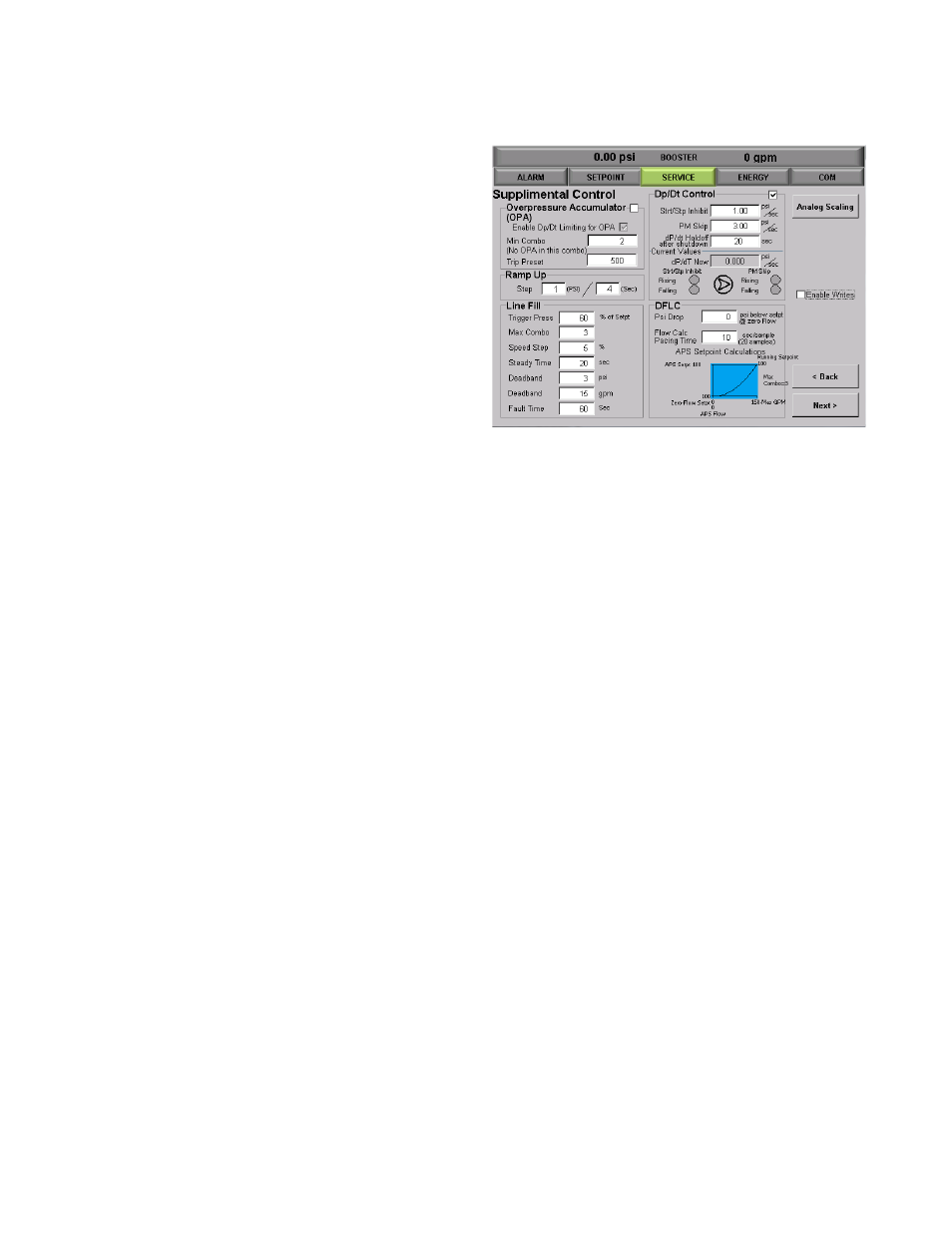

Figure 5 0 : Supplemental Control Home Screen

OPA Enable

This is a method used to shut down lag pumps

operating across-the-line in a system that uses both

VFD and XL (across-the-line) pumps. Check this box

to enable.

The overpressure accumulator measures the

overpressure, and calculates a value to add to the

Overpressure Accumulator depending on this error

on each program scan. The system will shut off a lag

pump when “Trip Preset” is reached.

Min combo:

Combo # on which, OPA is not desired because it is

preferred that the last pump stop in speed test.

Line Fill Mode

This configures how the XLS controller will respond

to powering up, or being put in “Auto”, under very low

pressure conditions. Under these conditions, air may

be in the system and it can be dangerous to the

piping to immediately start pumps and run full out to

attempt to bring pressure back too setpoint too

quickly.

The line fill system works by starting one main pump

at a fixed frequency (calculated from Speed @ 0 psi

startup) under PID control). The system will hold this

speed until pressure and flow are considered

“Steady” for a period of time. Then the system will

increase the speed. The process continues, possibly

starting additional pumps, until the max line fill

pressure is reached, at which time the system

switches over to “Ramp up” mode and continues.