Bell & Gossett 10-001-275 XLS Integrated Pump Controller User Manual

Page 11

11

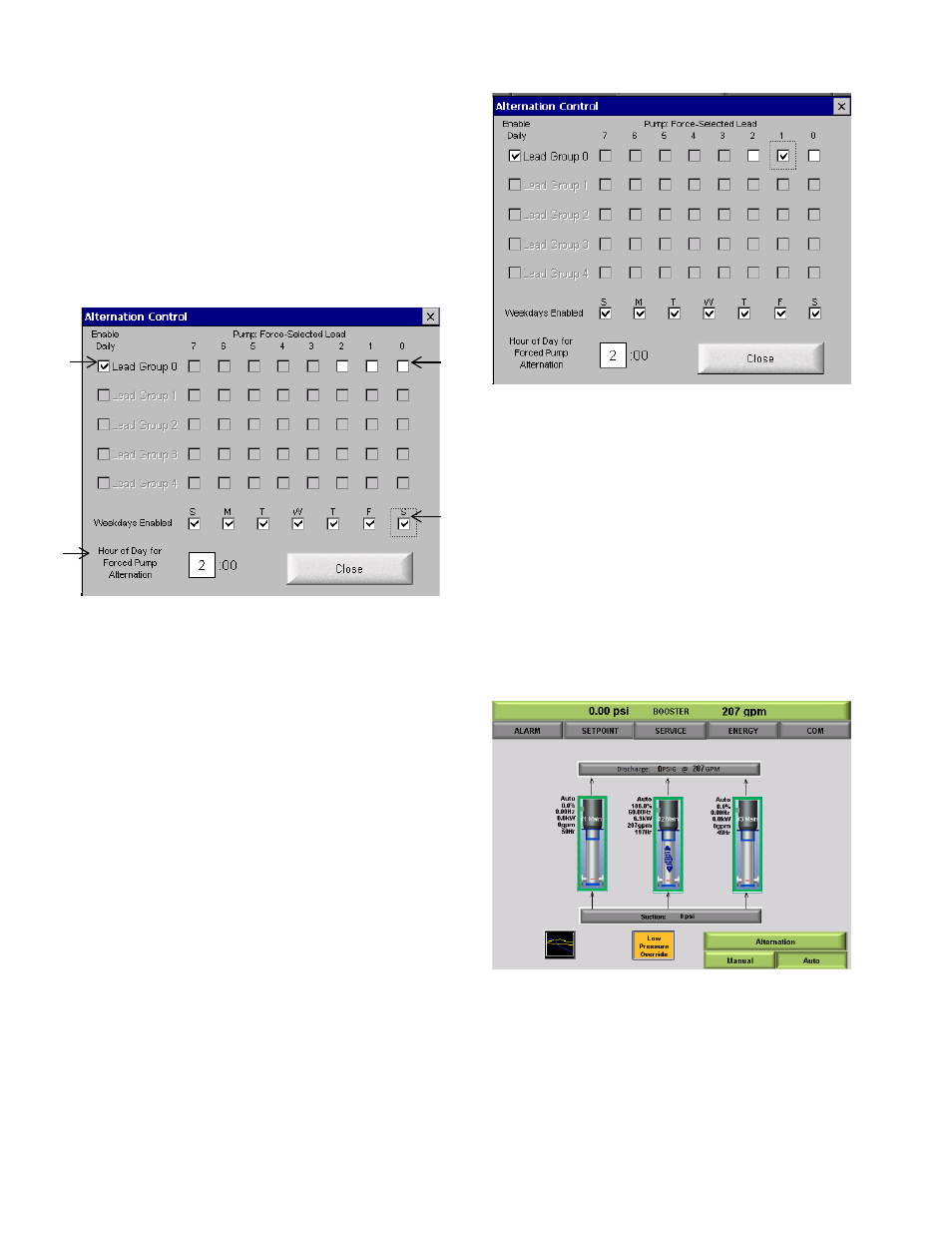

ALTERNATION SET UP

The default alternation sequence is set from the factory to

alternate the pumps every time a pump is turned off by the

system. The control will automatically select the pump with

the lowest number of run-hours every time a pump is

staged on/off.

By tapping [ALTERNATION] an enhanced screen shown

in Figure 19 will appear that allows the modification of

the alternation sequence for the station.

Figure 1 9 : Default Alternation Screen

The Alternation screen will allow the user to force

alternation of a given pump during a particular time of

day.

a. Enables forced alternation for given pump group

based on scheduled parameters in remaining

fields. Leaving this unchecked will disable the

forced alternation based on time of day. The

pumps will still alternate as they turn on and off

due to demand.

b. Sets the time for forcing alternation.

c. This section will default to the “unchecked”

position as shown. By ”checking” one of these

boxes, you will be forcing that pump to be the lead

pump when alternation occurs. Only one box

needs to be checked. If multiple boxes are

checked then the first checked pump from the right

will always be the lead pump.

d. Sets the day in which the system will force

alternation

Figure 2 0 : Example Alternation Screen

In the above example alternation will occur normally

anytime the pumps are turned off. However, alternation

will be forced daily at 2:00 a.m. with pump 1

established as the lead.

LOW PRESSURE OVERRIDE

The Low Pressure Override button allows the station’s

low pressure safeties to be disabled for system service.

This function will allow for the technician to perform

system checks without low pressure alarms shutting the

station down. This feature should never be left on

while the station is unattended.

Figure 2 1 : Low Pressure Override

a

b

d

c