Make up – Hawk Industries Hawkjaw Sr. Manual ALS Serial Numbers 1 to 100 User Manual

Page 23

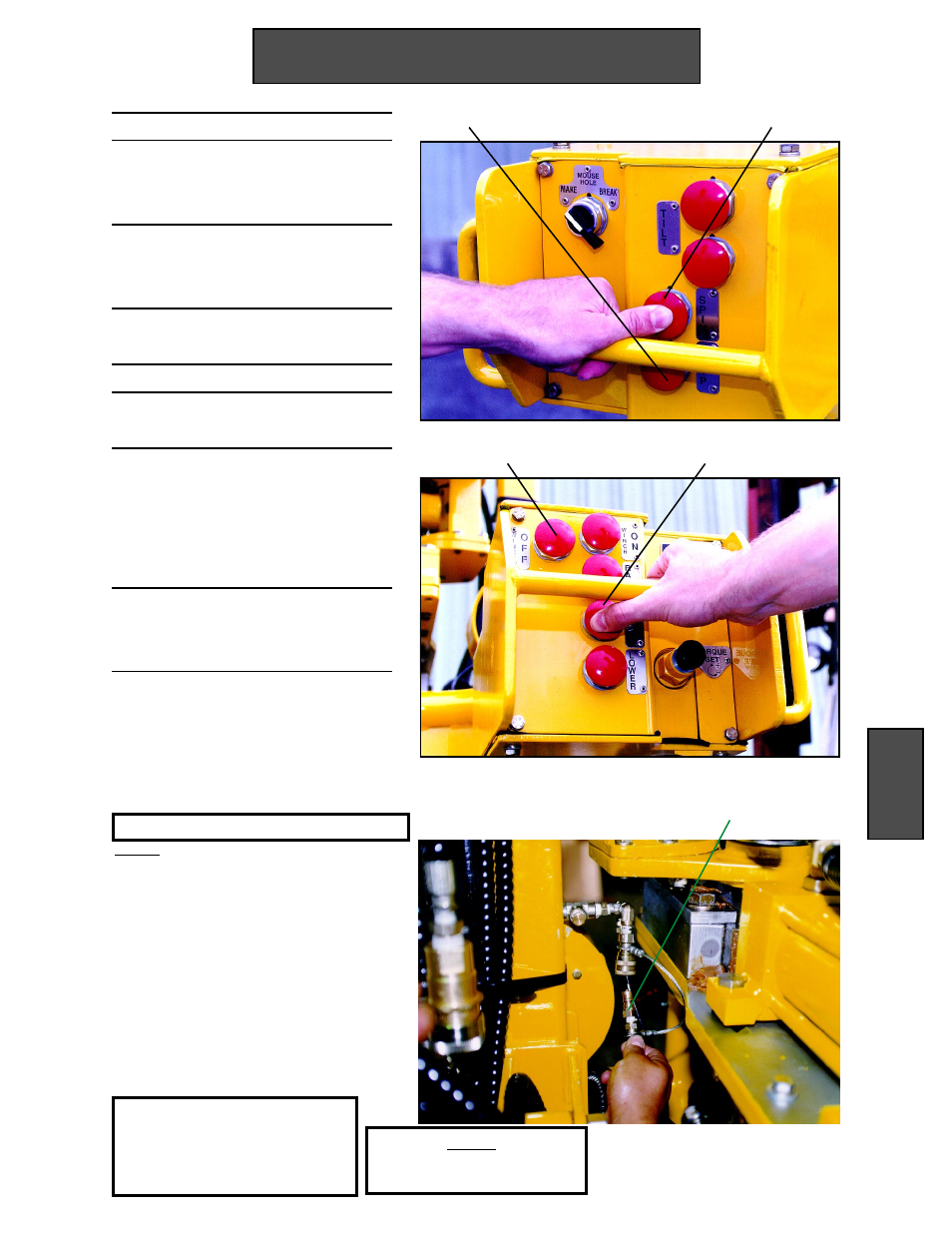

Make Up

1. Follow the steps on pages 17-22.

2. Make sure the Torque gauge

red needle (RN) is dialed to the

desired torque.

3. Push and hold down Spin (S)

until the stand rotates down to

the shoulder.

4. Release Spin (S). Immediately

push and hold down Grip (G).

5. Push and hold down Torque (T).

6. Watch the Torque gauge needle

(TN). *See note below

7. When the Torque gauge needle

rises above and settles at the

desired torque, release both

Torque (T) and Grip (G) at the

same time.

8. Push and hold down Winch Off

(WOff) to pull the HawkJaw off

the drill pipe connection.

Operation

23

G

S

WOff

T

*If the Torque cylinder strokes out before

the desired torque is reached, the Torque

gauge needle (TN) will fall off to approxi-

mately a 8000 Ft.-Lb. reading. If this

happens, release Torque (T). Immediately

release Grip (G). Wait for the Torque

cylinder to reset. Repeat Steps 5-8.

Operation

Test#1: Hawk strongly recommends testing

the Low Torque Warning System on every

trip. If this test procedure is not performed,

the drill string could be over torqued.

Disconnect the Low torque warning test

connector (LTC) located as shown. Torque

the first connection. Note the torque gage

needle position; keep the Hawkjaw positioned

on the same connection. Now re-connect the

Low Torque Warning Connector. Re-torque

the connection. The torque gage should

indicate the same reading. If it does not, see

Trouble Shooting page 96.

LOW TORQUE WARNING SYSTEM CHECK

Do not make up pipe with the low

torque warning test connector dis-

connected. This may result in under

torqued pipe in the hole.

WARNING

NOTE

For safety, push in the "E" stop

when the HawkJaw is at rest.

LTC