Calib rtmodule – Ashcroft ATE-100 Handheld LCD Digital Calibrator User Manual

Page 62

- 62-

Revision 4.6 3/2004

Section 27.0

Recertification of the Calibrator

Both the base unit and the pressure modules can be

recalibrated and recertified in the field. The base unit

includes a firmware based, menu driven procedure that

provides operator prompts to facilitate the recalibration

process. The procedure encompasses both the acquisi-

tion of “as found” data and performing adjustment and

recalibration of the base unit and modules. The recertifi-

cation program is accessed via the set up menu key.

Access Code

The calibration data is password protected with an

access code. The recalibration access code is different

than the owner access code. Both of the access codes

are provided with the calibrator at time of shipment and

are located on the base unit calibration certificate. If

the access code has been lost contact the factory and be

prepared to provide the serial number of the base unit.

The serial number is located on the product label in the

module bay of the base unit. To locate the product label

remove any installed pressure modules, hold the base

unit keypad side down and look into the module bays.

The label is located on the underside of the keypad/front

panel section of the base unit.

Section 27.1

Calibration/Recertification Overview

The base unit calibration firmware provides a means

of linearization and recertification of pressure modules

and the base unit’s electrical input (Vdc/mA) calibration

reference. In addition, the base unit employs a preci-

sion 1 VDC reference for interfacing with the modules

which can be calibrated. The calibration of this reference

is critical to ensure the combined output of pressure

module and base unit is within rated accuracy.

Section 27.2 Required Equipment

The following equipment is required to perform recali-

bration or recertification of the calibrator.

1. A precision voltage supply capable of providing

1 Vdc

±

50 microvolts (±0.00005 Vdc)

2. Primary pressure standard with an accuracy rating of

4:1 compared to the rating of the pressure module to

be tested.

3. Test leads with banana jacks and mini clips.

4. Recommended – Model CQS calibration quick

select module. Although recalibration and recertifica-

tion work can be performed with out it, this module

will greatly simplify the process and reduce risk of

damage to the base unit.

Section 27.3

As Received Readings of the

Base Unit Electronics

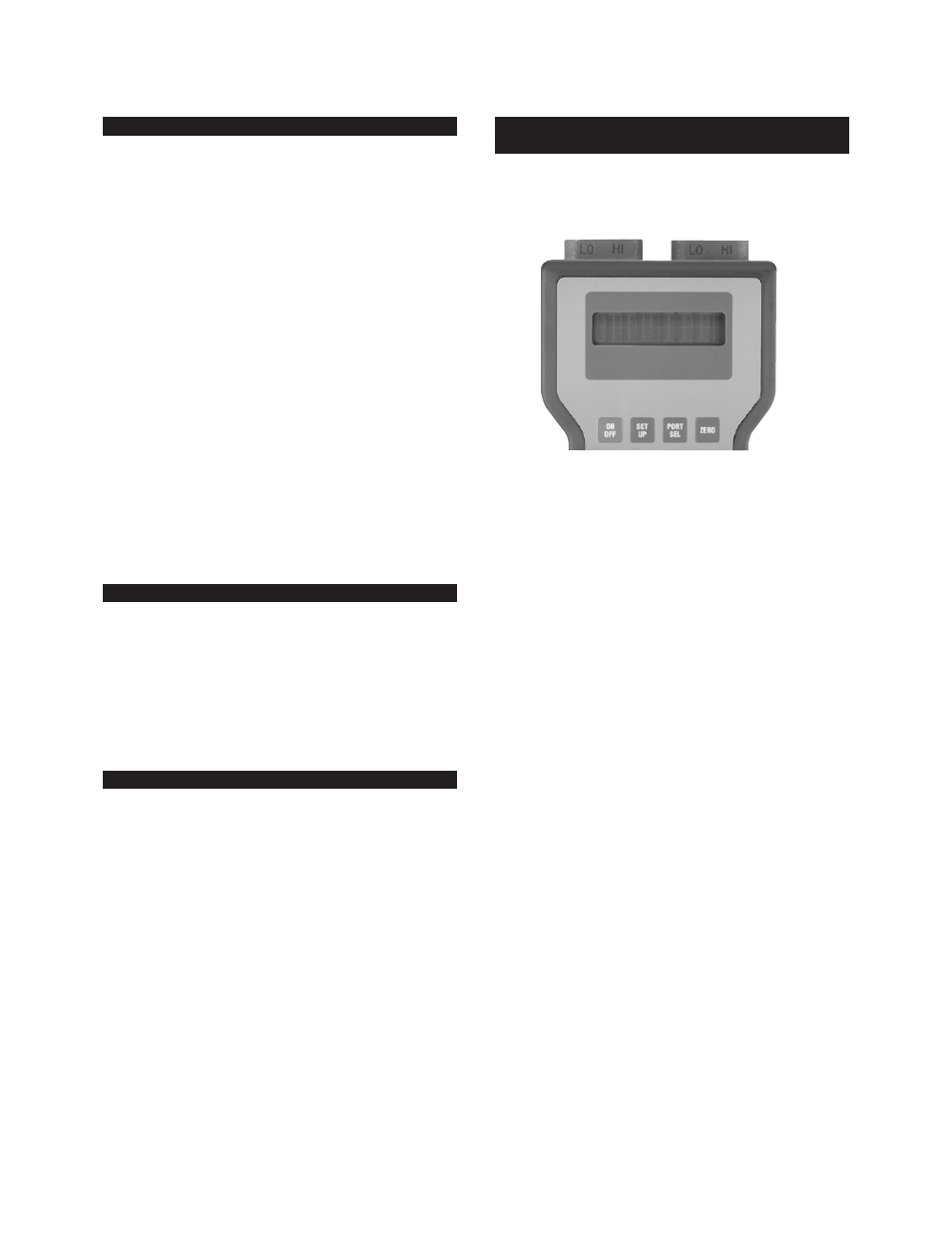

Please note. The following convention is used when

referring to modules or module bays in this procedure.

Step 1

Remove any installed measurement modules.

If the CQS calibration module is to be used, install it in

module bay #1 at this time.

Step 2

Turn power on and allow for at least 15 minutes

warm up time.

Step 3

With the calibrator powered up and displaying a

dashed line across the display, press the set up key.

SET

UP

Step 4

Using the arrow keys locate the text “Calib” in

the set up menu.

Calib RTmodule

Using the arrow keys select the text “Calib” from the

set up menu. When the calibration function has been

selected it will flash on the display.

Step 5

With the text “Calib” displayed and flashing

press the enter key.

ENT

Step 6

The calibrator will respond by displaying:

Access code ?

.00000

Step 7

Enter the 5 digit calibration access code pro-

vided with the base unit.

Access code ?

12345

Note:

The access code is specific for the base unit being

used. The code is provided on the certification sheet that

Module Bay #1

Module Bay #2