Ashcroft 1132 - Differential Pressure Gauge User Manual

Installation instructions for ashcroft

Installation Instructions for ASHCROFT

®

Explosion Proof Differential Pressure

Gauge/Switch, Variation XEK

Types 1130, 1131, 1132

© 2007 Ashcroft Inc., 250 East Main Street, Stratford, CT 06614-5145, USA, Tel: 203-378-8281, Fax: 203-385-0499, www.ashcroft.com

All sales subject to standard terms and conditions of sale. I&M008-10100-5/29 AMR 2C09/09

For efficient working of your gauge, please read all instructions

carefully before attempting to install.

CAUTION: Do not exceed maximum operating pressure given

on the gauge label. Check fluid compatibility with wetted parts

before use.

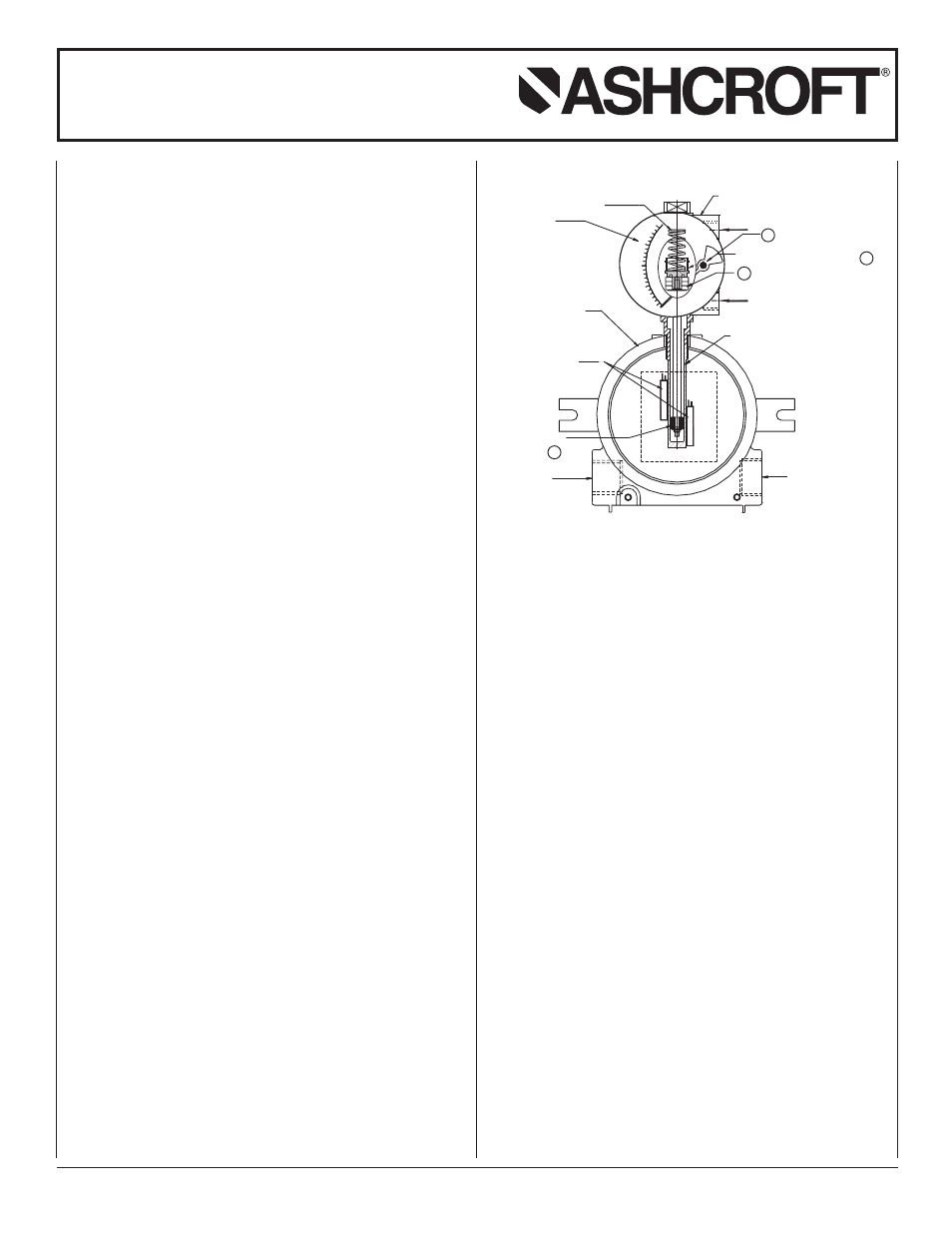

OPERATING PRINCIPLE

Variations in pressure between high and low ports is sensed by

a piston or diaphragm sensor

➀

which moves in proportion to

the pressure difference. A primary magnet

➁

is attached to the

sensor and moves with it in the same proportion. A rotary mag-

net

➂

with pointer is magnetically coupled with the primary

magnet, and is situated in an isolated cavity. Movement of rotary

magnet with pointer indicates differential pressure on the dial.

Process fluids are isolated from dial case and switch enclosure.

SWITCH: An auxiliary magnet

➃

situated in the tube extension

moves with the pressure sensors. Reed switches mounted on

the extension tube are activated due to interaction between

switch contacts and field of the auxiliary magnet. Switches can

be adjusted to open or close at preset points.

Note: The gauges are calibrated to give ±2%full scale accuracy

on ascending readings.

INSTALLATION

Depressurize the system and connect the high and low pres-

sure lines of your system to the “High” and “Low” ports of the

gauge, respectively.

Apply “High” and “Low” pressures simultaneously, to avoid dam-

age to the internal parts. If pressure exceeds the rated maxi-

mum pressure, “O” rings used on male connectors, and the

teflon seal inside the pressure chamber of piston instrument will

be damaged. In diaphragm instrument diaphragm may rupture.

If maximum operating pressure is within the allowable limit, but

the differential pressure exceeds gauge range, there will be no

damage to the gauge. Pointer will only go the extreme right end

of the scale.

EXPLOSION PROOF SWITCH INFORMATION

Switches and electrical connections are mounted in an explosion

proof enclosure with UL, CSA, FM and CENELEC approval. The

enclosure meets Class 1, Groups B, C, D, Class 2, Groups E, F,

G, Class, NEMA 7 & 9 and IP66. There are two

3

⁄

4

˝ electrical

condiut connections.

PRECAUTIONS

Do not connect “High” and “Low” ports to wrong pipe ends. Do

not subject the gauge to excessive vibration. The gauge is never

to be used in an area where a magnetic field is present. It may

affect readings.

As the gauge works on magnetic coupling principal, use only

non magnetic fittings, parts etc. in areas closer than 2˝ on all

sides, otherwise calibration will be affected.

Do not try to open any part of the gauge for any reason,

because if not reassembled properly, calibration and operation

will be affected.

SPST OR SPDT

MAGNET

3/4 NPT

CONDUIT PORT

AUXILIARY

SWITCH ENCLOSURE

REED SWITCH

ONE OR TWO

ADJUSTABLE

3/4 NPT

CONDUIT PORT

SENSING ELEMENT

PRESSURE EXTENSIONTUBE

HIGH PORT

PISTON OR DIAPHRAGM

RANGE SCALE

RANGE SPRING

D. P. GAUGE HOUSING

LOW PORT

0

5

10

15

20

25

2

1

3

4