Ashcroft 2462 - Receiver Gauges User Manual

Ashcroft Measuring instruments

TYPE 1279 & 1379 SOLID FRONT

DURAGAUGE PRESSURE GAUGE

LIQUID FILL CONVERSION

INSTRUCTIONS

© 2007 Ashcroft Inc., 250 East Main Street, Stratford, CT 06614 USA, Tel: 203-378-8281, Fax 203-385-0402 www.ashcroft.com

All sales subject to standard terms and conditions of sale. All rights reserved. I&M008-10090 (84B276) Rev 5/05 P5/07

1. Unscrew front threaded ring (turn CCW).

Remove and discard glass window. For

range spans 60 psi and under, shift pointer

down scale by the amount shown in the

table. With either the glass or plastic win-

dow, replace the O-ring with one furnished

in the kit.

2. Remove protective paper from acrylic plas-

tic window taking care not to scratch win-

dow. Assemble window in gauge.

3. Moisten face of threaded ring with silicone

oil or silicone grease where ring bears up

against window. Replace front threaded

ring and tighten firmly hand tight. See

instructions on reverse side for applying

proper torque to ring to establish desired

squeeze on O-ring seal. (Fig. 4).

It is important to hold gauge rigidly, other-

wise ring lugs may be damaged during

removal or assembly process.

4. From rear of gauge, remove and discard

these parts: rear cover and cover gaskets

from case.

Note: Disregard Step No.s 5a and 5b if

converting to hermetically sealed version.

When converting a 45-1379 with the top fill

hole configuration, p/n 256A176-01 fill plug

is required and must be ordered separately.

5. Filling Procedures:

a. Manual Filling Procedure: Place gauge

face down on bench and tip gauge by

blocking up front with a

3

⁄

8

inch block at

the 12 o’clock dial position. Tipping of

the gauge is necessary so fluid will flow

into front cavity of the case. Pour in fill

liquid to within about

1

⁄

16

inch of rear

seal lip. When bubbles stop rising, front

cavity is filled. Remove

3

⁄

8

inch block and

pour in liquid until level is about

1

⁄

16

inch

below rear sealing lip.

Note: An alternative method of filling is to

fill the front dial cavity, adding the front

window, etc., as in Step No. 3. Then fill

the rear of the gauge. This method elimi-

nates the need to tip the gauge.

b. Vacuum Pump Fill Procedure: (This

procedure is recommended when filling

a large number of gauges.) Place gauge

face down and insert a

1

⁄

8

inch diameter

tube, connected to a vacuum pump,

through the 12 o’clock position hole in

the rear, solid front portion of the case

(see Fig. 5). Evacuate the air from the

front dial cavity while pouring in the fill

fluid through the case back. The vacuum

will displace the air with fluid. When the

dial cavity is solidly filled, remove the

tubing and continue to pour the fill fluid

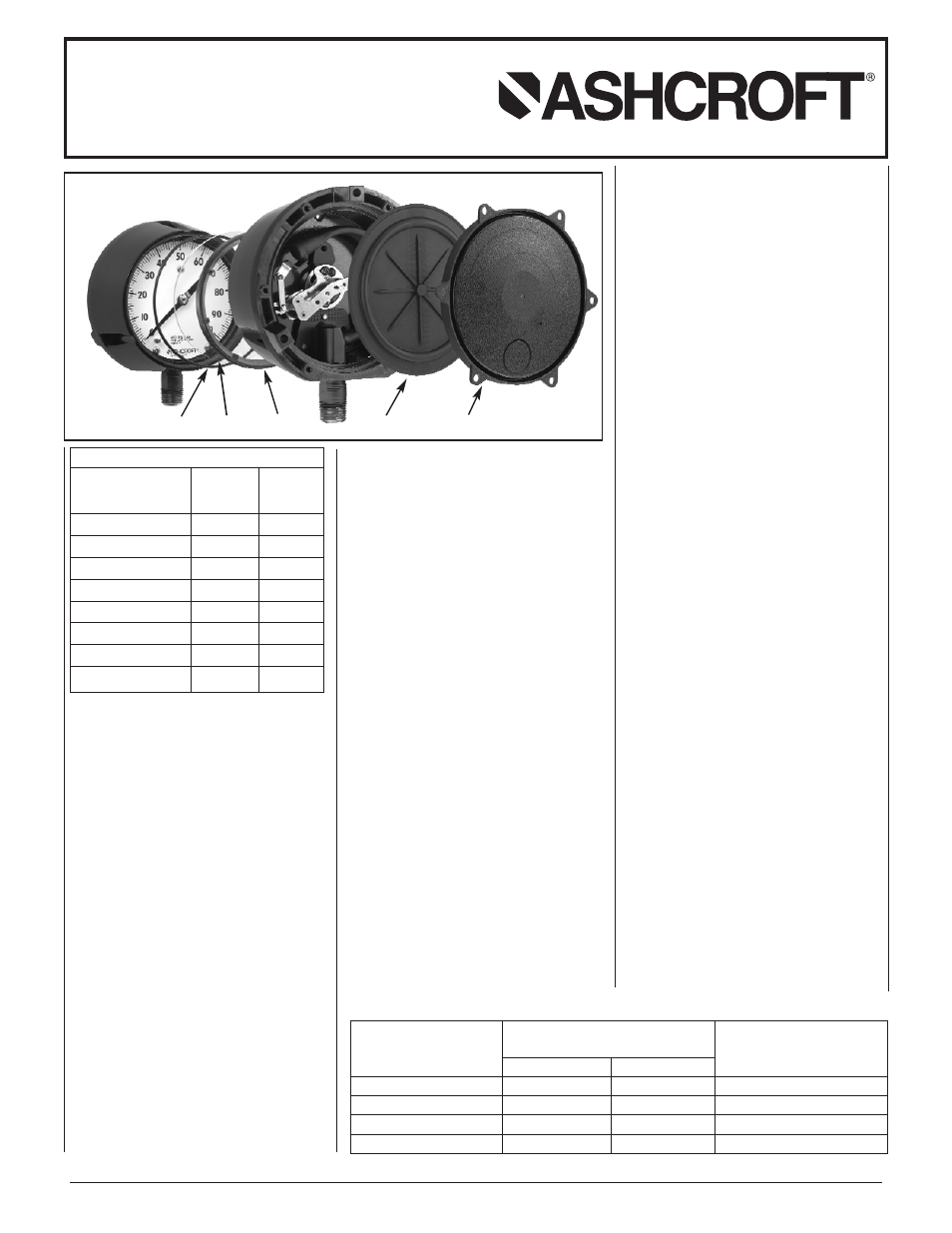

TYPICAL 45-1279_S-04L-100* GAUGE

SHOWN WITH KIT 101A202-01

LIST OF INCLUDED PARTS

4

1

⁄

2

˝ LOWER

4

1

⁄

2

˝ BACK

CONN.

CONN.

DESCRIPTION

101A202-01

101A203-01

ACRYLIC WINDOW

1

1

FRONT O-RING

1

1

DIAPHRAGM

1

1

REAR COVER

1

1

COVER SCREWS

4

4

THROTTLE SCREWS

2

2

GARTER SPRING

–

1

FILL IDENTIFICATION

1

1

“O” Ring

Acrylic Window

Threaded Ring

Elastomeric Diaphragm

with Integral “O” Ring

Rear Cover

to within

1

⁄

16

inch BELOW the O-ring

channel lip.

Pre-measuring fill amount is not nec-

essary with above methods. For refer-

ence, amount of fill is approximately

400 ml. or 14 fluid oz. (4

1

⁄

2

˝ GA.) and

455 ml. or 16 fluid oz. (6˝ GA.).

c. Note: The liquid fill level should be

3

⁄

8

˝

(±

1

⁄

8

) as measured from the inside of the

ring at the 12:00 o’clock position.

6. On lower connection gauges, assemble

rear seal diaphragm to case.

For back connection gauges see instruc-

tions on reverse side. (Fig. 2/4).

7. Assemble rear cover and six self tapping

screws in a criss-cross pattern.

Assemble throttle screw to threaded hole in

socket.

Note: If system is monel (socket wrench

flat stamped “PHS” or “PH”) use monel

throttle screw.

8. Check appropriate box on fill identification

label, and peel off label back, and attach fill

label to gauge case.

9. If gauge is to be repackaged:

a. Include enclosed instruction sheet inside

carton.

b. Change type number on carton label to:

(1) Hermetically Sealed – 1279(*)SH.

(2) Liquid Filled – 1279(*)SL.

*Bourdon Tube System Code

Ambient

60 psi and Under

Temp. Limits

Down Scale Zero

°F °C

Shift

Required

Weatherproof

–50/150

–45/65

N/A

Hermetically Sealed

–10/125

–25/50

N/A

Glycerin Filled

0/150

30/65

.15 psi

Silicone Filled

–50/150

–45/65

.12 psi

Glycerin or silicone should not be used in

applications involving Oxygen, Chlorine, Nitric

Acid, Hydrogen Peroxide or other strong oxi-

dizing agents, because of danger of sponta-

neous chemical reaction, ignition or explo-

sion. Halocarbon should be specified.

Products with this fill can be ordered from

factory.

The use of fluids other than those listed in the

table above (for example, Hydrocarbon-based

oils) may result in leakage caused by a reac-

tion between the fluid and the elastomeric

seals. Consult the factory before filling with

any other fluid.