1 incremental encoders – NORD Drivesystems BU0510 User Manual

Page 12

POSICON position control for NORD frequency inverters, SK 530E and above

12

Subject to technical alterations

BU 0510 GB-3911

2.2.1

Incremental encoders

According to the resolution (pulse number), incremental encoders generate a defined number of pulses for

each rotation of the encoder shaft (Track A / Track A inverse) With this, the precise speed of the encoder or

motor can be measured by the frequency inverter. By the use of a second track (B / B inverse) shifted by

90° (¼ period), the direction of rotation can also be determined. In turn, the "zero track" (0 / 0 inverse)

provides exactly one pulse per rotation and can therefore be used as a referencing signal for positioning

systems.

The voltage source can be an external source or the internal voltage (according to the frequency inverter

version: 12V /15V /24V).

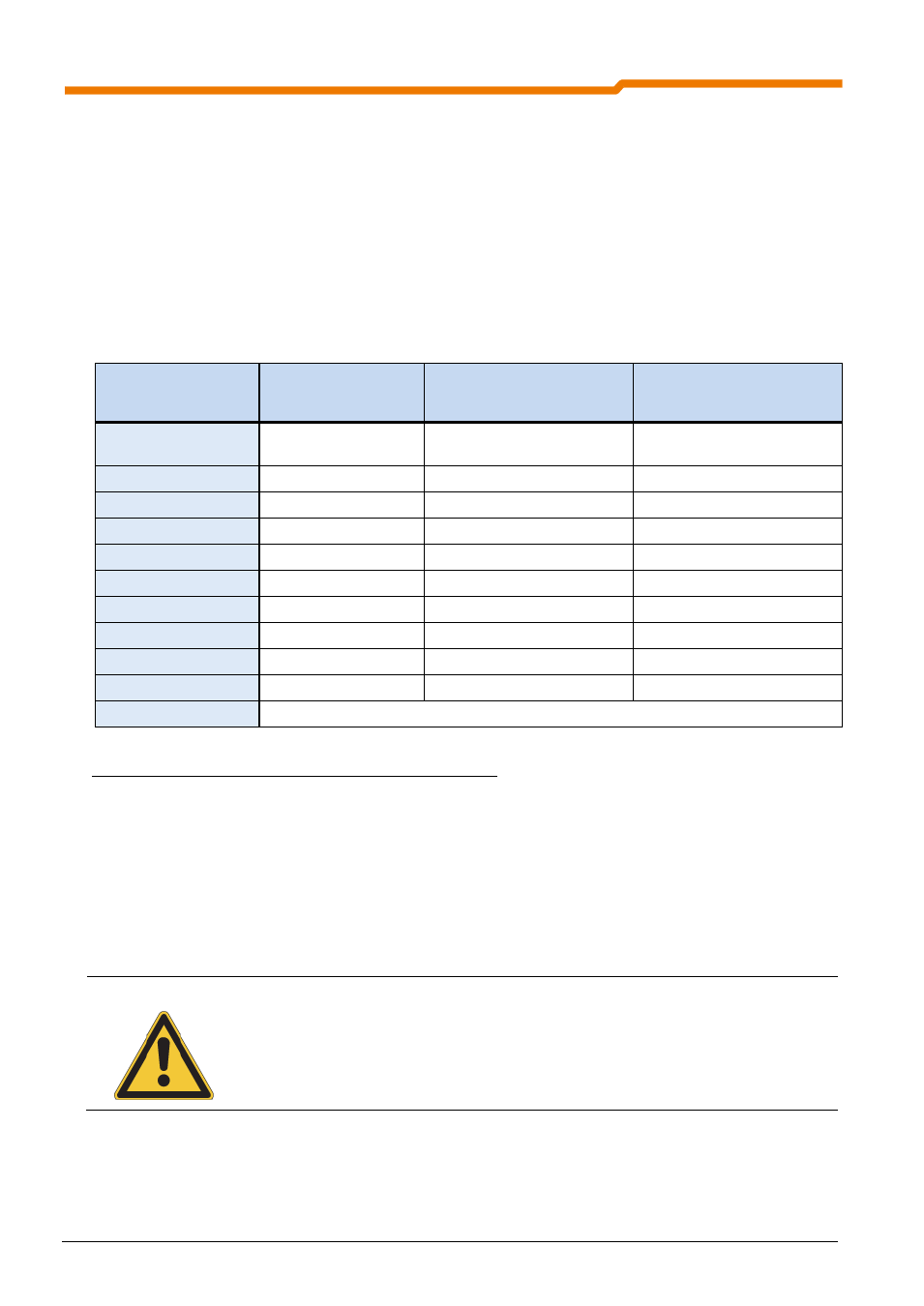

Function

Cable colours,

for incremental

encoder

Assignment for SK 53xE

Assignment for SK 54xE*

10-30V supply

brown / green

X5:42(/44)

15V (/24V)

X5:42( /X5:44 /X6:49)

15V ( /24V /12V)

0V supply

white / green

X6:40 GND/0V

X5:40 GND/0V

Track A

brown

X6:51 ENC A+

X6:51 ENC A+

Track A inverse

green

X6:52 ENC A-

X6:52 ENC A-

Track B

grey

X6:53 ENC B+

X6:53 ENC B+

Track B inverse

pink

X6:54 ENC B+

X6:54 ENC B+

Track 0

red

--

X14:63 CLK +

Track 0 inverse

black

--

X14:64 CLK-

+ 5V Sense

blue

--

X14:65 DAT +

0V Sense

white

--

X14:66 DAT -

Cable shield

connected to a large area of the frequency inverter housing or shielding angle

*Zero track not necessary for speed feedback or operation of asynchronous machines.

Table 1: Connection assignments for incremental encoders

Evaluation of the zero track and the Sense signal is necessary for the operation of PMSM (Permanent Magnet

Synchronous Motors). The zero impulse is then used for synchronisation of the rotor position. The offset

between the zero pulse and the actual "zero" rotor position is set in parameter P334 "Encoder offset". If the

Sense cable (+5V Sense and 0V Sense) is not connected, there is no synchronisation to the zero pulse. The

zero track is not required for asynchronous machines. Alternative to the commutation of the position,

Hiperface, BISS, Endat or SSI encoders with additional Sin/Cos or incremental tracks may be used.

NOTE

If there are deviations from the standard equipment (Type 5820.0H40, 10-30V encoder,

TTL/RS422) for the motors, please note the accompanying data sheet or consult your supplier.