Troubleshooting – Badger Meter M-Series M2000 User Manual

Page 56

TROUBLESHOOTING

The M2000 mag meter is designed for many years of optimal performance However, should it malfunction, there are certain

things that we recommend you check before contacting our Technical Support department or your local Badger Meter

Representative

NOTE:

N

If the fluid measured has a high concentration of conductive solids, deposits may accumulate on the internal

liner walls and electrodes These deposits will cause a reduction of the measuring output Thus, Badger Meter

recommends that you remove the meter and inspect the liner and electrodes after six months If deposits are found,

remove them with a soft brush Repeat inspection process every six months or until an appropriate inspection cycle

can be established for the specific application

NOTE:

N

Other general conditions include:

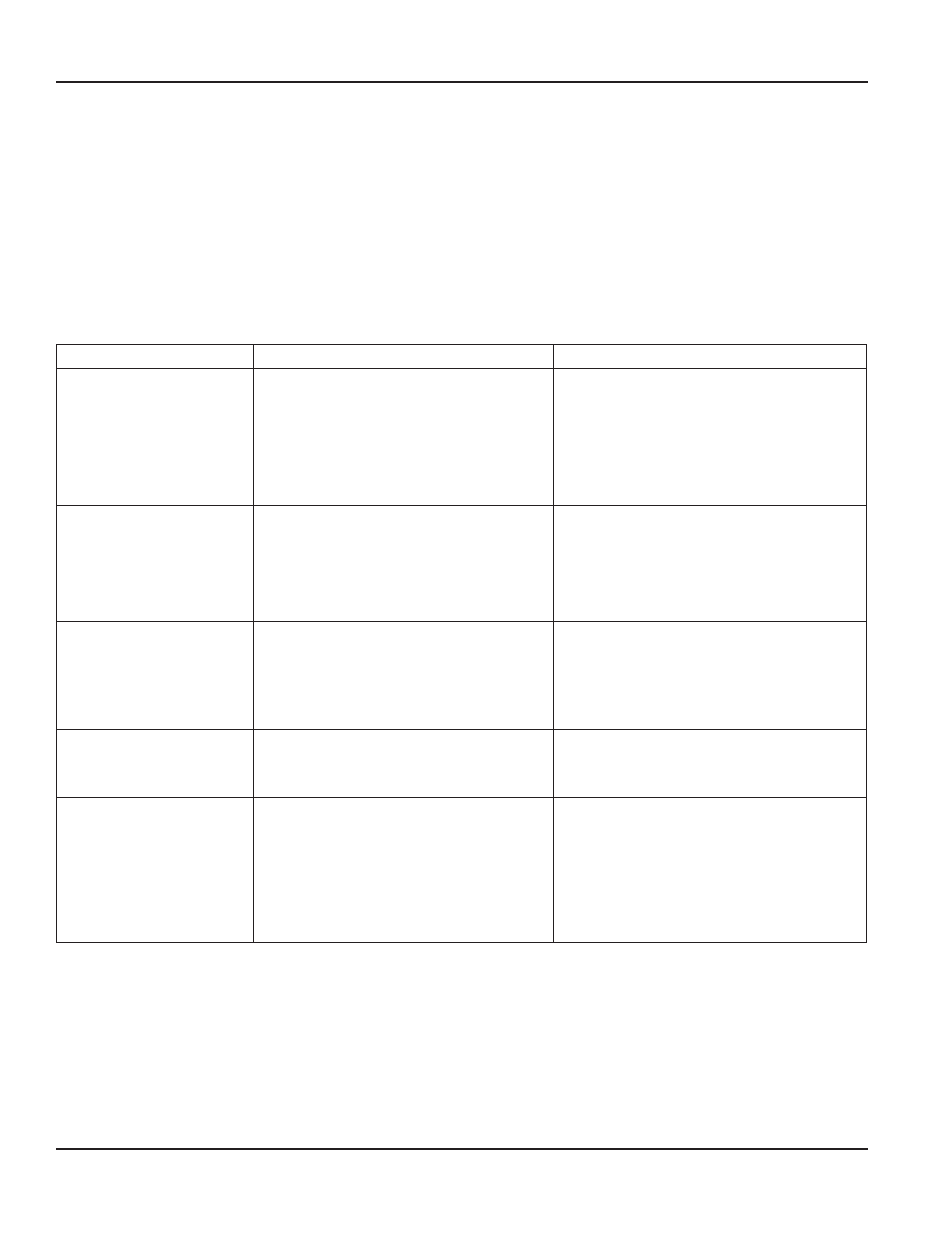

Description

Possible Cause

Recommended Action

Flow is present but display

is "0"

Digital input is holding flow

Disconnected signal cable

Detector mounted opposite of the main

flow direction (see arrow on the nameplate)

Coil or electrode cables exchanged

Improper low flow cutoff or full scale flow

Check signal cable

Turn detector by 180° or switch terminal E1

and E2 or reprogram to bidirectional mode

Check cable connections for cross wiring

Verify digital input configuration

Replace configuration defaults

Inaccurate measuring

Improper calibration

Wrong calibration parameter

Pipe not fully filled, or air in pipe

Invalid fluid conductivity

Invalid fluid mixture

Restore calibration defaults

Check the parameters (detector factor and

size) according to supplied data sheet

Check if meter is completely filled with fluid

Purge line to eliminate air bubbles

No display

No power

Incorrect power

Bad wiring connections

Blown fuse

Apply power

Check power value

Replace fuse (2 amp, 250V AC, slow blow

5 x 20 mm)

Check display ribbon cable

Flow rate value known to be

wrong

Detector factor

Deposits on electrodes and/or liner

Incorrect pipe size programmed

Check value on label

Check and remove deposits

Check size if necessary

Flow rate indication

unstable

Cable issue

Grounding issue

Partially full pipe

Air in pipe

Amplifier location – outside electrical

Invalid fluid conductivity

Make sure cable is shielded and not vibrating

Make sure meter is properly grounded to a

good earth ground

Make sure pipe is full of fluid

Make sure fluid does not contain air bubbles

Make sure amplifier is not too close to sources

of electrical interference

M-Series® M2000 Electromagnetic Flow Meter

Page 56

August 2012