Straight pipe requirements, Pipe reducer requirements, Figure 8: straight pipe requirements – Badger Meter M-Series M2000 User Manual

Page 10

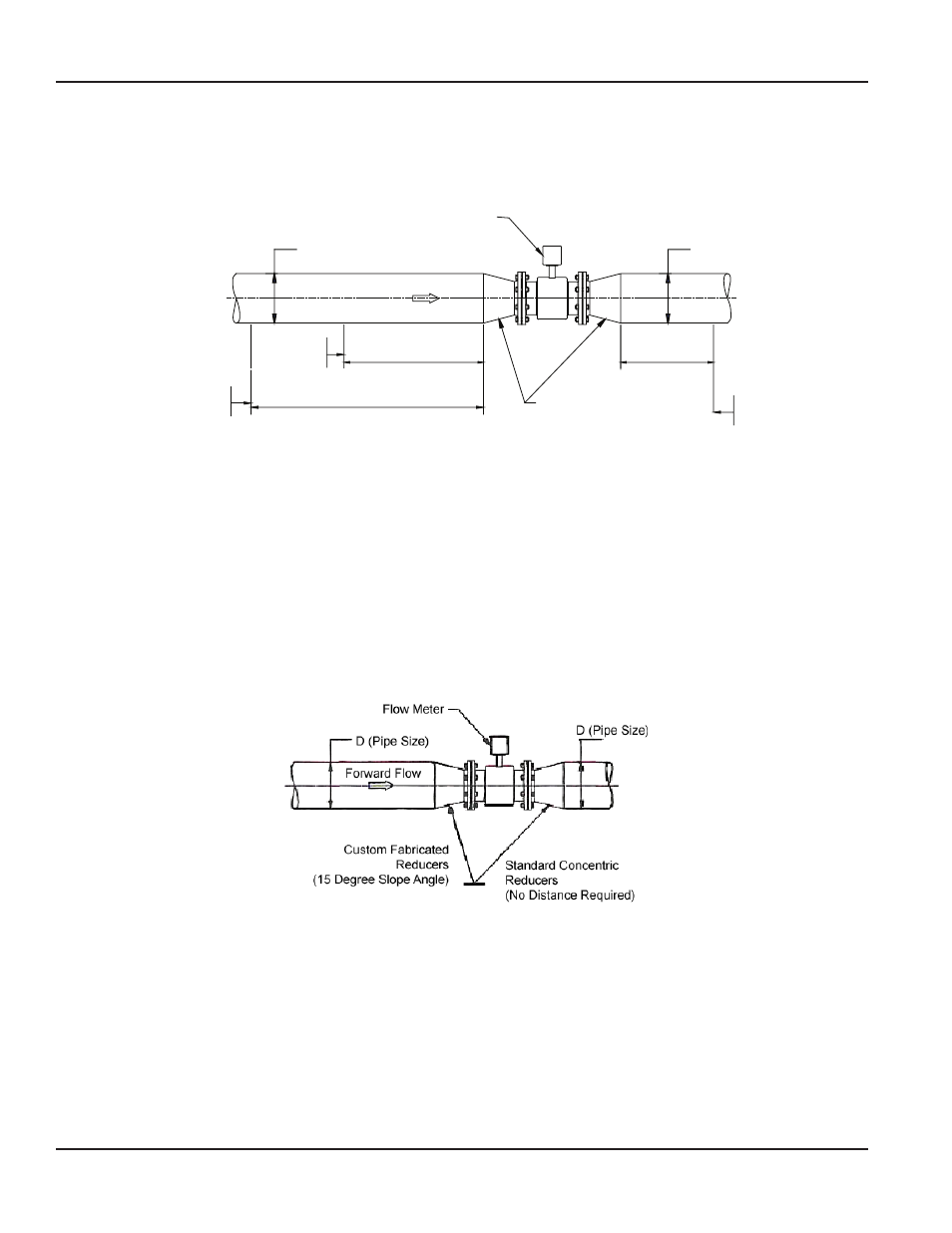

Straight Pipe Requirements

Sufficient straight-pipe runs are required at the detector inlet and outlet for optimum meter accuracy and performance An

equivalent of three diameters of straight pipe is required on the inlet (upstream) side Two diameters are required on the outlet

(downstream) side

FORWARD FLOW

MINIMUM STRAIGHT PIPE

MINIMUM STRAIGHT PIPE

ELBOW

TEE

GATE VALVE

(FULLY OPEN)

MINIMUM STRAIGHT PIPE

CHECK VALVE

GLOBE VALVE

BUTTERFLY VALVE

PUMP

ELBOW

TEE

ANY VALVE

FLOWMETER

3 x D

7 x D

2 x D

D (Pipe Size)

D (Pipe Size)

MINIMUM PIPING REQUIREMENT

STANDARD CONCENTRIC

REDUCERS

(NO DISTANCE REQUIRED)

Figure 8: Straight Pipe Requirements

Pipe Reducer Requirements

With pipe reducers, a smaller meter can be mounted in larger pipelines This arrangement may increase low-flow accuracy

There are no special requirements for standard, concentric, pipe reducers

Custom fabricated pipe reducers must have an approximate slope angle of 15 degrees to minimize flow disturbances and

excessive loss of head If this is not possible, install the custom pipe reducers as if they were fittings and install the required

amount of straight pipe

Figure 9: Pipe Reducer Requirements

M-Series® M2000 Electromagnetic Flow Meter

Page 10

August 2012