Technical data – KROHNE OPTISWIRL 4070 EN User Manual

Page 72

8

TECHNICAL DATA

72

OPTISWIRL 4070

www.krohne.com

02/2013 - 4000150606 MA OPTISWIRL4070C R07 en

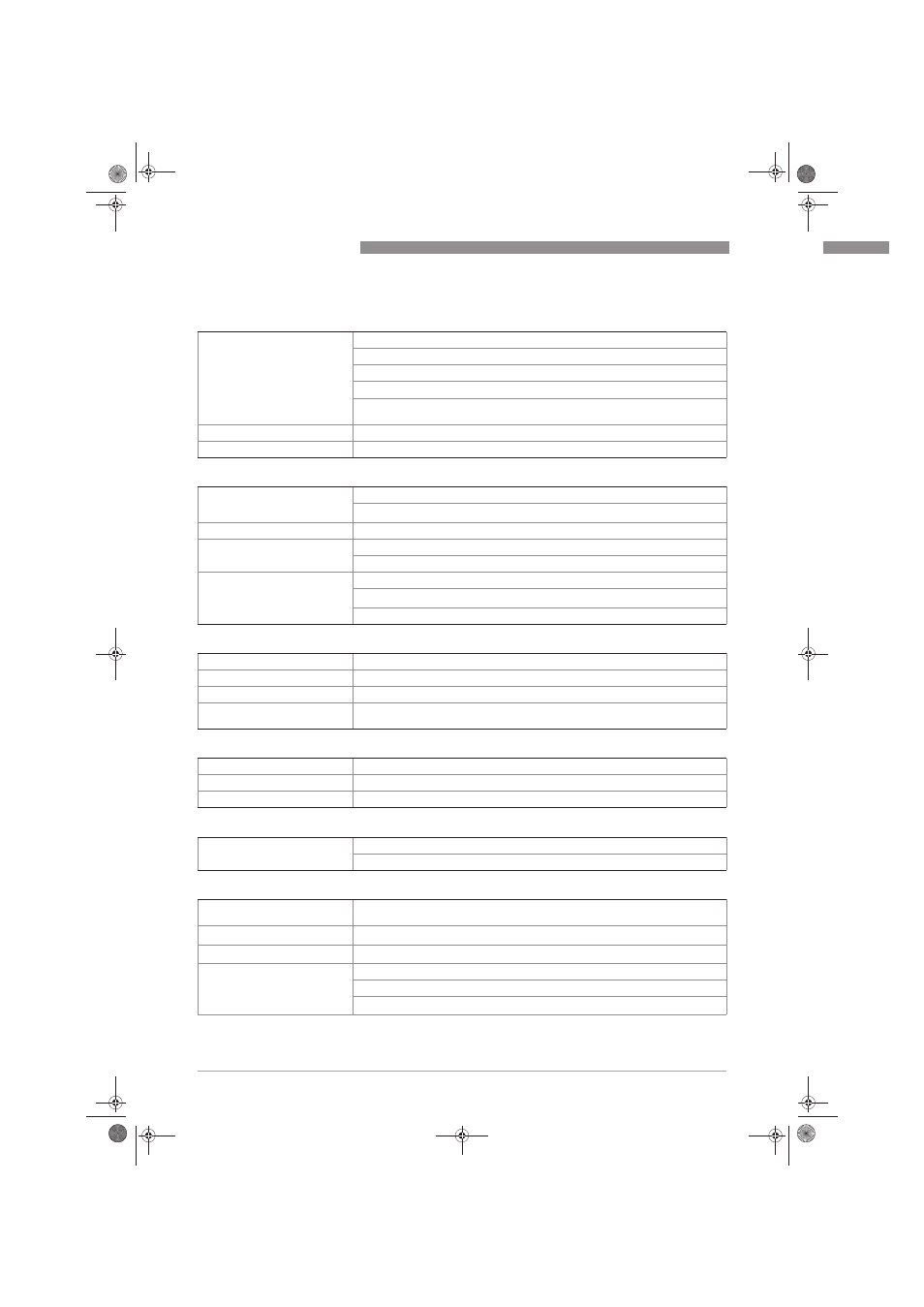

Installation conditions

Inlet run

≥ 20 x DN (without disturbing flow, after pipe narrowing, after a single 90° bend)

≥ 30 x DN (after a double bend 2x90°)

≥ 40 x DN (after a double three-dimensional bend 2x90°)

≥ 50 x DN (after control valves)

≥ 2 DN before flow straightener; ≥ 8 DN after flow straightener (specified values

apply only to original ≥ 20 DN inlet run)

Outlet run

≥ 5 x DN

Dimensions and weights

For detailed information refer to chapter "Dimensions and weights".

Materials

Measuring sensor and process

connections

Standard: 1.4404/316L

Option: Hastelloy

®

C-22 on request

Converter housing

Die-cast Aluminium

Pressure sensor gasket

Standard: FPM

Option: FFKM

Measuring tube gasket

Standard: 1.4435/316L

Option: Hastelloy

®

C-276

Selection depends on measuring sensor material/medium.

Process connections Flange version

DIN EN 1092-1

DN15...300 in PN16…100

ASME B16.5

½

...12" in 150…600 lb

JIS B 2220

DN15...300 in JIS 10…20 K

For detailed information on combination flange/pressure rating, refer to chapter

"Dimensions and weights".

Process connections Sandwich version

DIN

DN15...100 in PN100 (higher pressures on request)

ASME

½

...4" in 600 lb (higher pressures on request)

JIS

DN15...100 in 10…20 K (higher pressures on request)

Electrical connections

Power supply

Non-Ex: 14…36 VDC

Ex: 14…30 VDC

Current output

Description of the used

abbreviations

U

ext

= external voltage; R

L

= load + resistance

Measuring range

4...20 mA (max. 20.8 mA) + HART

®

protocol

Load

Minimum 0 Ω; maximum R

L

= ((U

ext

- 14 VDC) / 22 mA)

Error signal

Acc. to NAMUR NE43

Upper value: ≥ 21.0 mA

Lower value: ≤ 3.6 mA (not with HART

®

protocol)

MA_OPTISWIRL4070C_R07_en_150606_PRT.book Page 72 Wednesday, February 13, 2013 2:47 PM