Device description – KROHNE OPTISWIRL 4070 EN User Manual

Page 16

2

DEVICE DESCRIPTION

16

OPTISWIRL 4070

www.krohne.com

02/2013 - 4000150606 MA OPTISWIRL4070C R07 en

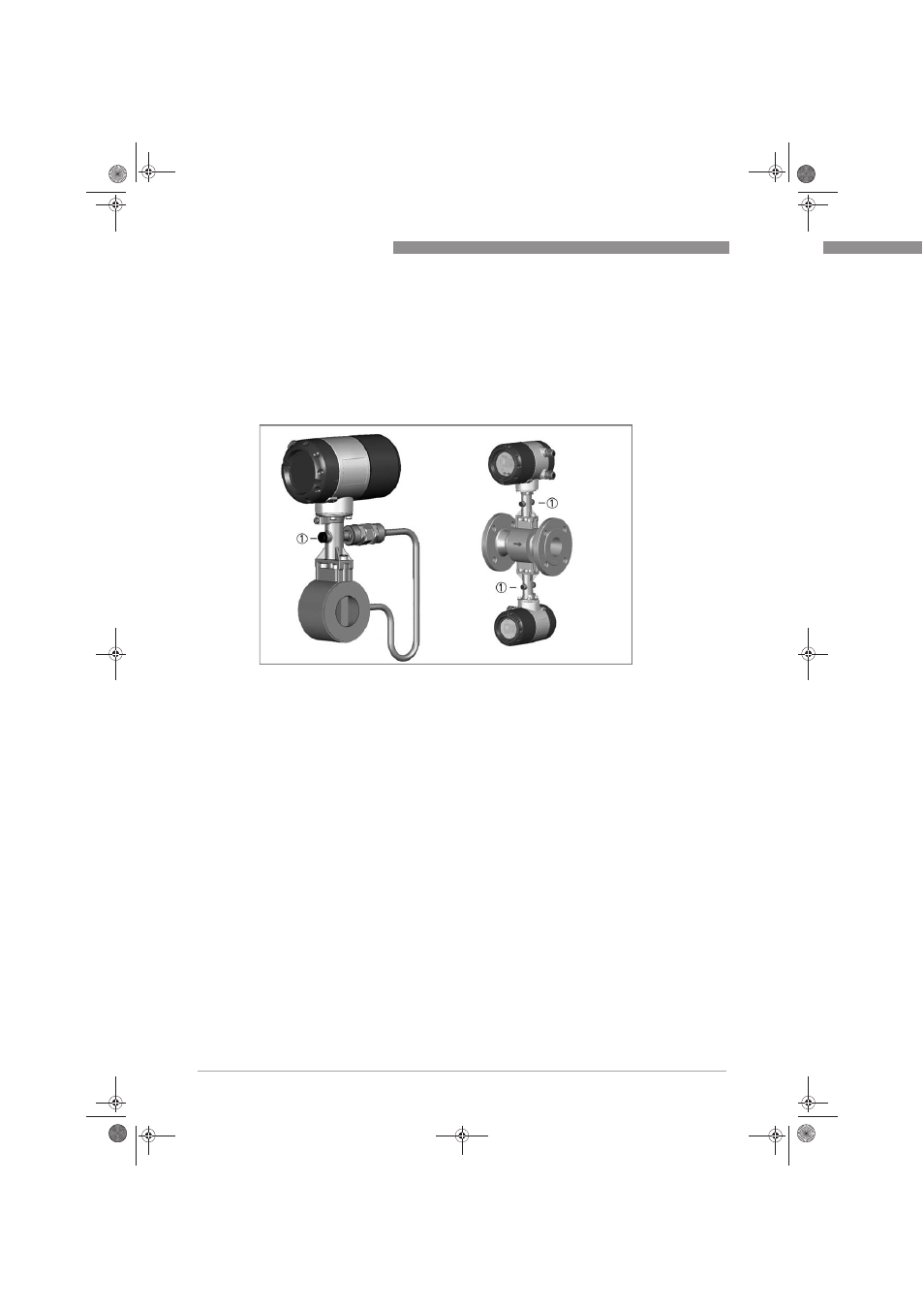

2.2.8 Dual seal

To cover the requirements of ANSI/ISA-12.27.01-2003 “Requirements for Process Sealing

Between Electrical Systems and Flammable or Combustible Process Fluid” Dual seal, a

membrane vent is integrated in the neck of the instrument. This vent works in the improbable

case of a leakage as an annunciation valve between the primary seal (Process) and secondary

seal (electronic compartment).

The sealing between the pick-up and the Flow tube is considered as the primary seal. Its

construction material is always the same as the Flow tube itself (e.g. Stainless steel 316L or

Hastelloy C22). Chemicals used for the process, going through the Flow tube, must be

compatible with the designated material.

By using the membrane vent as annunciation valve, all requirements for a dual seal device in

accordance to above mentioned standard, are fulfilled.

• It protects the electronic compartment against access by process media, due to possible

leakages.

• The leakage of the primary seal is visible.

Regular maintenance should be performed by the customer to ensure this Dual Seal notification

system is working properly or that there is no leak.

If a leakage is noticed:

The manufacturer service should be contacted for servicing or replacement of the meter.

1 Annunciation valve (Membrane vent)

MA_OPTISWIRL4070C_R07_en_150606_PRT.book Page 16 Wednesday, February 13, 2013 2:47 PM