IAI America TTA User Manual

Page 71

-71/85-

Normal

re

spon

se

(Con

tinued

from

th

e pre

v

iou

s

p

age)

Single-a

x

is sta

tu

s

(

*1)

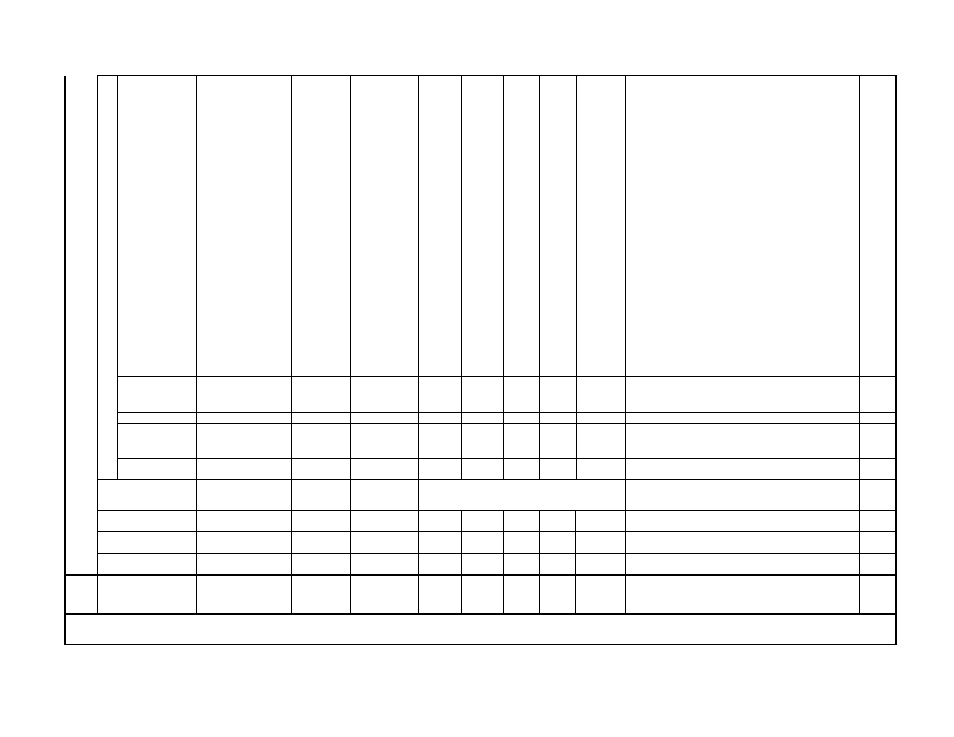

Axis status

'XX(h)'

2

24

Bit 0 (Servo axis in use): 0 = Not in use / 1 = In use (moving, etc.)

* “Servo axis in use” indicates that a given task has the right to use

the applicable axis. Therefore, this bit will turn ON not only when an

operation command involving axis movement is in progress (including

when an axis is moving), but also in the following conditions:

Servo is starting up from an OFF state

Servo is shutting down from an ON state (excluding emergency stop)

Operation axis is paused

Bits 1, 2 (Home return): 0 = Not yet performed / 1 = Returning to home /

2 = Completed

Bit 3 (Servo): 0 = OFF / 1 = ON

Bit 4 (Operation command successful completion): 0 = Not yet

complete / 1 = Completed successfully

* Can be used only for completion check after an operation command.

(For positioning that includes any of the X, Y and R-axes, be sure to

check completion for all of the X, Y and R-axes.)

Bit 5 (Push error detection): 0 = Not detected / 1 = Detected

Bits 6, 7 (Reserved for system use)

* Check method for operation command positioning under IAI protocol

After an IAI-protocol operation command is executed, turning OFF (Not

in use) of bit 0 (Servo axis in use) will be monitored for the applicable

axis.

When “Not in use” is detected, the cause will be checked based on the

conditions of bit 4 (Operation command successful completion) and bit

5 (Push error detection) (three causes are shown below):

(1) [Bit 0 (Servo axis in use) = OFF] AND [Bit 4 (Operation command

successful completion) = ON]

---

Positioning

has

completed successfully.

(2) [Bit 0 (Servo axis in use) = OFF] AND [Bit 5 (Push error detection) =

ON]

--- Push error (* Need not be checked if push command is not

used.)

(3) [Bit 0 (Servo axis in use) = OFF] AND [bit 4 (Operation command

successful completion) = OFF] AND [Bit 5 (Push error detection) =

OFF]

--- Operation cancellation due to error, emergency stop, etc.

Axis sensor input

status

'X(h)' 1

25

Bit 0 (Creep sensor): 0 = OFF / 1 = ON

Bit 1 (Overrun sensor): 0 = OFF / 1 = ON

Bit 2 (Home sensor): 0 = OFF / 1 = ON

Bit 3: (Reserved for system use)

Axis error code

'XXX(h)'

3

28

Encoder status (at

reset)

'XX(h)' 2

30

Bit 0 (Overspeed (OS))

Bit 1 (Full absolute status (FS))

Bit 2 (Count error (CE))

Bit 3 (Counter overflow (OF))

Bit 4 (Reserved for system use) Bit 5 (Multi-rotation error (ME))

Bit 6 (Battery error (BE))

Bit 7 (Battery alarm (BA))

Current position

'XXXXXXXX(h)'

8

38

0.001 mm or

0.001 deg

Long-type data (hexadecimal ASCII code)

Single-axis status

repetition for remaining

axes

Data indicated by *1 for

the number of

remaining axes

MAX

112

MAX

150

Refer to the data indicated by *1.

Data indicated by *1 x Number of remaining effective axes = 16 bytes x

(Max 8 – 1) = Max 112 bytes

SC 'XX(h)'

2

MAX

152

CR 0Dh

1

MAX

153

LF 0Ah

1

MAX

154

Error

respon

se

Error response format

Refer to the error

response format.

10 10

(Note 1)

Add H (or h) at the end of each data expressed in hexadecimal notation. If there is no H or h at the end, the data is considered a decimal.

(Note 2)

Data enclosed in single quotation marks indicates an ASCII code. Data is a hexadecimal ASCII code if (h) is added before the closing quotation mark, or a decimal ASCII code if (d) is added before the closing

quotation mark.