IAI America PCON-CFA User Manual

Page 54

2. ACON-C/CG,

PCON-C/CG

48

CompoNet

2.7.6

Remote I/O Mode 2 (Number of occupied channels 6CH)

This is the operation mode with the position No. set up as the same as using PIO (24V I/O).

Set the position data using the teaching tools such as PC software.

The number of operable positions varies depending on the parameter No. 25 “PIO Pattern” setting.

This mode is the same as the remote I/O mode, but the current-position read function and command-current

read function are also available.

The features of each PIO pattern are shown below. (Refer to Operation Manual for the controller main body for

more information)

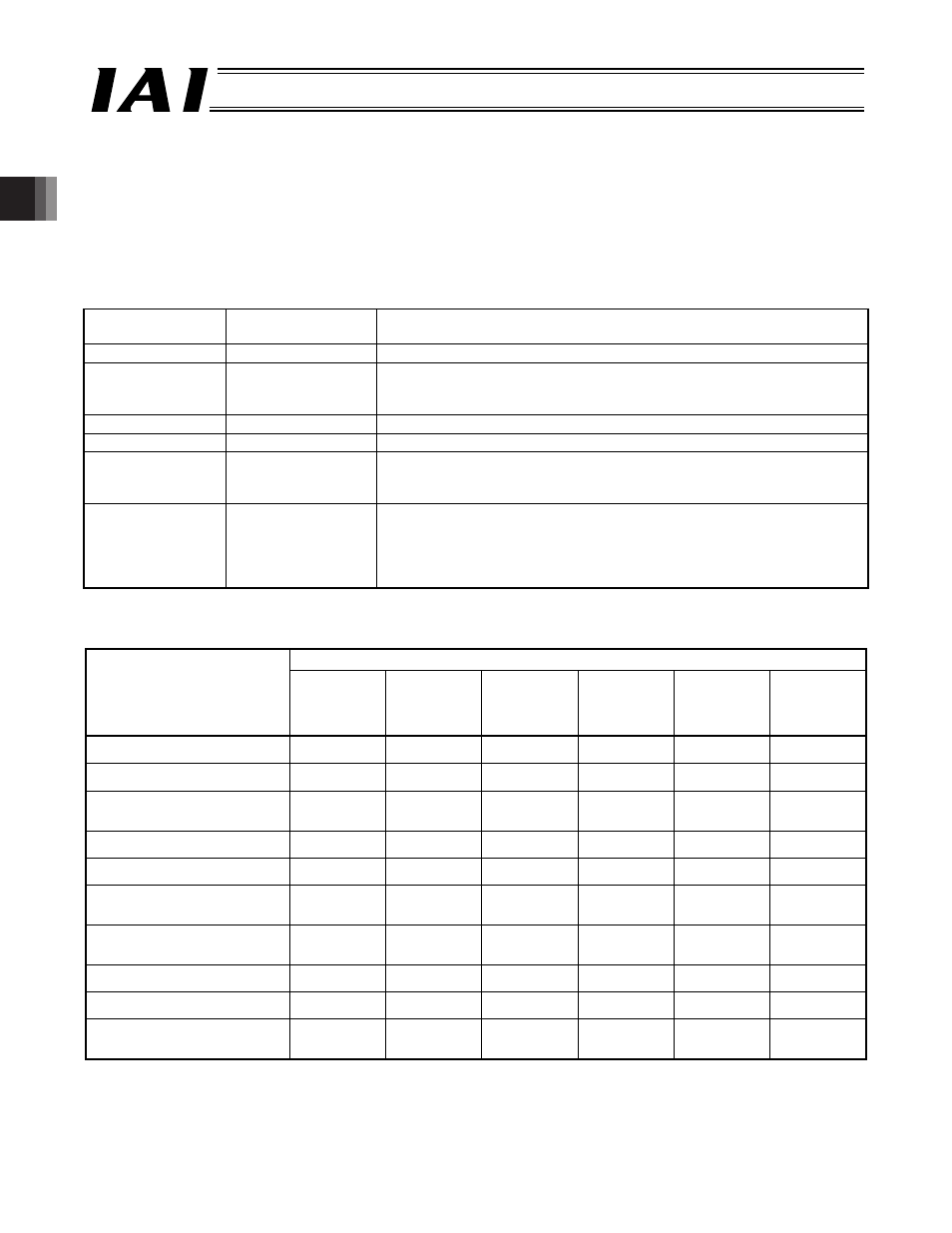

Value set in parameter

No. 25

Operation Mode

I/O Specification

0 Positioning

mode

64 positioning points and two zone output points are available.

1 Teaching

mode

64 positioning points and one zone output point are available.

Positioning operation and jog operation are supported.

The current position can be written to a specified position.

2 256-point

mode

256 positioning points and one zone output point are available.

3 512-point

mode

512 positioning points are available. There are no zone outputs.

4 Electromagnetic

valve

mode 1

7 positioning points and two zone output points are available.

The direct operation command is available for each position No.

A position complete signal is output for each position number.

5 Electromagnetic

valve

mode 2

3 positioning points and two zone output points are available.

The actuator is operated by specifying forward, backward and intermediate

position commands.

A position complete signal is output separately for the front end, rear end and

intermediate position.

The robot cylinder's effective main functions that can be controlled using this mode, are as shown in the

following table.

PIO Pattern

ROBO cylinder function

0:

Positioning

mode

1:

Teaching

mode

2:

256-point

mode

3:

512-point

mode

4:

Electro-

magnetic

valve mode 1

5:

Electro-

magnetic

valve mode 2

Home-return operation

{

{

{

{

{

x

Positioning operation

{

{

{

{

{

{

Speed and acceleration/

deceleration setting

{

{

{

{

{

{

Pitch feed (inching)

{

{

{

{

{

{

Pressing Operation

{

{

{

{

{

x

Speed change during the

movement

{

{

{

{

{

{

Operation at different

acceleration and deceleration

{

{

{

{

{

{

Pause

{

{

{

{

{

{ (*1)

Zone signal output

{

{

{

x

{

{

PIO pattern selection

(set by a parameter)

{

{

{

{

{

{

{

:Supported, x:Not supported

(*1) It is available when the parameter No. 27 “Movement Command Type” is set to “0”.

Turning “OFF” the “Movement Command” can stop the system temporarily.