IAI America ICS(P)A User Manual

Page 12

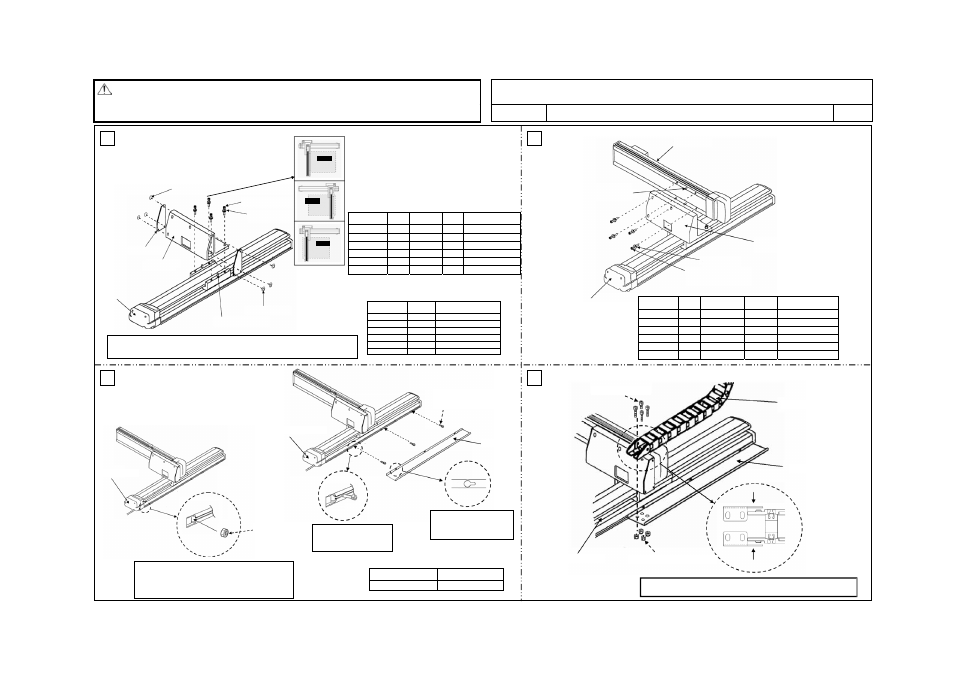

ICS(P)A Cartesian Robot, 2-axis Configuration XYB (Y-axis Base Mount) Type

ICS(P)A2-B

-CT Cable

Track

Caution:

x Although each part has been chamfered to remove sharp edges, exercise due caution

during the assembly to prevent injury. If necessary, wear gloves or other protective gears.

x Exercise due caution during the assembly to prevent pinching of hands and fingers.

Drawing No.

GMM08-004

1/2

* This assembly procedure applies to combination direction 1. If other combination direction such as 2, 3 or 4 is used, the actuator and bracket directions vary. However, you can still use this assembly drawing as a reference.

3

4

Flange-head hexagonal

socket head bolt

Tightening torque

M4x6mm 18kgf

xcm/176Nxcm

1

2

Configuration

type

Parallel

pin

Hexagonal

bolt

High-

tension

Tightening torque

ICS(P)A-BA

6x15

M6x30mm

M6 54.7kgf

xcm/536Nxcm

ICS(P)A-BB

8x18

M8x35mm

M8 306kgf

xcm/2997Nxcm

ICS(P)A-BC

8x18

M8x35mm

M8 306kgf

xcm/2997Nxcm

ICS(P)A-BD

8x18

M8x35mm

M8 306kgf

xcm/2997Nxcm

ICS(P)A-BE

8x18

M8x35mm

M8 306kgf

xcm/2997Nxcm

ICS(P)A-BF

8x18

M8x35mm

M8 306kgf

xcm/2997Nxcm

Configuration

type

Thin-head

screw

Tightening torque

ICS(P)A-BA

M3x6mm

8.9kgf

xcm/87.2Nxcm

ICS(P)A-BB

M3x6mm

8.9kgf

xcm/87.2Nxcm

ICS(P)A-BC

M4x6mm

20.8kgf

xcm/204Nxcm

ICS(P)A-BD

M4x6mm

20.8kgf

xcm/204Nxcm

ICS(P)A-BE

M4x6mm

20.8kgf

xcm/204Nxcm

ICS(P)A-BF

M4x6mm

20.8kgf

xcm/204Nxcm

Configuration

type

Parallel

pin

Hexagonal

socket head bolt

Dedicated

washer

Tightening torque

ICS(P)A-BA

6x15 M6x20mm Not

required

54.7kgf

xcm/536Nxcm

ICS(P)A-BB

6x15 M6x20mm Not

required

54.7kgf

xcm/536Nxcm

ICS(P)A-BC

8x18 M8x28mm Required

306kgf

xcm/2997Nxcm

ICS(P)A-BD

8x18 M8x28mm Required

306kgf

xcm/2997Nxcm

ICS(P)A-BE

8x18 M8x28mm Required

306kgf

xcm/2997Nxcm

ICS(P)A-BF

8x18 M8x28mm Required

306kgf

xcm/2997Nxcm

[Tools] Allen wrench

In the case of configuration direction types 2 to 4,

the actuator and bracket directions are different.

Thin-head screw (3 pcs)

[5] Bracket cover

[1] X-Y bracket

Thin-head screw (3 pcs)

Parallel pin (1 pc or 2 pcs)

Hexagonal socket

head bolt (4 pcs)

High-tension washer

Type 2

(Reverse of type 1)

Type 3

(Y-axis installed on

opposite side)

Type 4

(Reverse of type 3)

X-axis: IS(P)A

Note: To ensure squareness between the X-axis and Y-axis, insert one parallel pin.

Adjust the angle between the X-axis and Y-axis to the right angle, and then mount

the hexagonal bolts.

Y-axis: IS(P)A

[1] X-Y bracket

Parallel pin (2 pcs)

Dedicated washer

Hexagonal socket head bolt (4 pcs)

X-axis: IS(P)A

[Installation of Y-axis: IS(P)A on X-Y bracket [1]]

M6 x 8 mm (4 pcs)

[10] Cable track

[9] Guide rail

M6 hexagonal nut (4 pcs)

X-axis: IS(P)A

X-axis: IS(P)A

X-axis: IS(P)A

[9] Guide rail

The M4 hexagonal nut in the slot provided on the

side face of the X-axis, before the guide rail [9] is

installed. The number of hexagonal nuts to be

placed in the slot varies according to the stroke.

Install the bolts before

the guide rail [9] is

installed.

Install the bolts by

hooking them in the

holes in the guide rail [9].

[Installation of guide rail [9] on X-axis: IS(P)A]

M4 hexagonal nut

Flange-head hexagonal

socket head bolt

M4 x 6 mm

[Installation of X-Y bracket [1] on X-axis: IS(P)A]

[Installation of bracket cover [5] on X-Y bracket [1]]

Follow “Instruction for Cable Track Type Wiring (Drawing No. GMM12-001)”

for how to lay out the wiring inside a cable track.