Archive, Troubleshooting guide (cont.), Evolver 202 robotic atomizers - maintenance – Ransburg Evolver 202 Solvent A11918-XXX User Manual

Page 56

AA-07-01

5 1

5 1

5 1

5 1

5 1

Evolver 202 Robotic Atomizers - Maintenance

TROUBLESHOOTING GUIDE (Cont.)

TROUBLESHOOTING GUIDE (Cont.)

TROUBLESHOOTING GUIDE (Cont.)

TROUBLESHOOTING GUIDE (Cont.)

TROUBLESHOOTING GUIDE (Cont.)

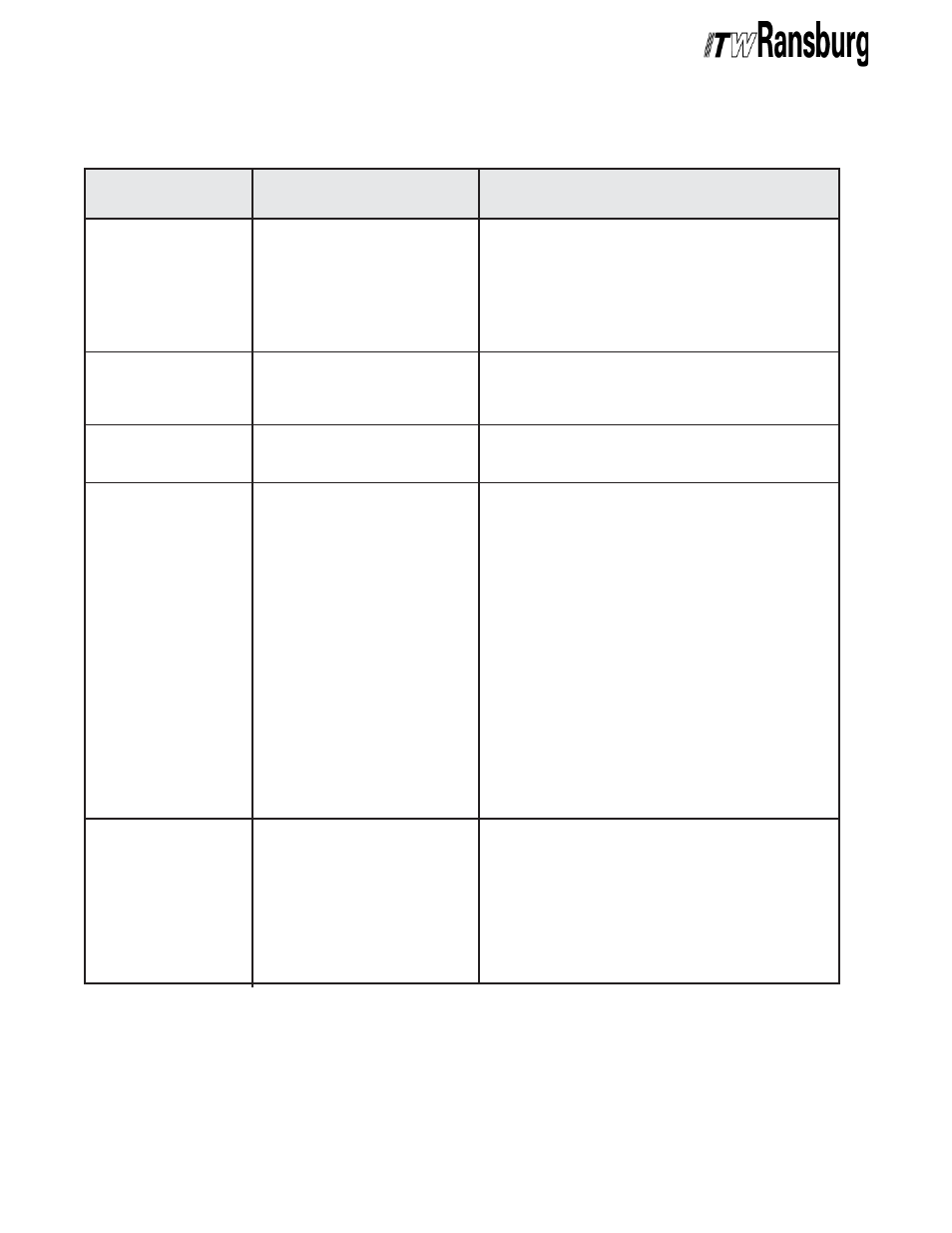

General Problem

General Problem

General Problem

General Problem

General Problem

Possible Causes

Possible Causes

Possible Causes

Possible Causes

Possible Causes

Corrective Action

Corrective Action

Corrective Action

Corrective Action

Corrective Action

No Electrostatics

No Electrostatics

No Electrostatics

No Electrostatics

No Electrostatics

Low kV, High μA

Low kV, High μA

Low kV, High μA

Low kV, High μA

Low kV, High μA

Output

Output

Output

Output

Output

Low kV, Low μA

Low kV, Low μA

Low kV, Low μA

Low kV, Low μA

Low kV, Low μA

Output

Output

Output

Output

Output

No Fluid Flow

No Fluid Flow

No Fluid Flow

No Fluid Flow

No Fluid Flow

Continuous Fluid

Continuous Fluid

Continuous Fluid

Continuous Fluid

Continuous Fluid

Flow

Flow

Flow

Flow

Flow

1. Cascade not functioning

1. Exterior of applicator

contaminated with conduc-

tive material

1. Cascade failure

1. Fluid valve does not actuate

2. Clogged fluid tube

3. Bad transceiver module

4. Plugged inlet

5. Regulator (needle and seat)

stuck

6. No pilot air

7. Two component valve

contaminated

8. In-line mix tube clogged

1. Fluid valve open

2. Fluid valve seat damaged or

worn

3. Regulator (needle and seat)

dirty

4. Regulator pilot air not shut

off

1. Check low voltage cable and harness timing

mark positions. Correct as required.

2. Cascade bad. Replace as required.

3. Low voltage cable connections wrong at

MicroPak.

4. Low voltage cable bad. Replace as required.

1. Replace applicator cover.

2. Clean exterior with a non-polar solvent.

1. Replace as required.

1.a. Verify that air pilot signal is present.

b. Fluid valve air pilot pressure is too low.

Increase air pressure to 70 psig minimum.

c. Replace fluid valve.

2. Remove and inspect fluid tube.

3. Replace transceiver module.

4. Flush clean

5. Remove and clean or replace

6. Check air pilot

7. Remove valve manifold and clean

8. Replace

1 a. Remove air pilot signal.

b. If still open, replace fluid valve.

2. Replace fluid valve seat.

3. Remove and clean or replace.

4. Check air supply.

ARCHIVE